Chapter: Aquaculture Engineering : Heating and Cooling

Composite heating systems - Aquaculture Engineering

Composite heating

systems

A composite heating system is normally used to heat water for

use in fish farming. The system comprises several components that all have some

heating effect on the inlet water. Usually there are one or several heat

exchangers in addition to either a heat pump on large farms, or a heater or an

oil burner on smaller farms. The COP is calculated for the entire heating

system and are usually in the range 15ŌĆō25, which means that for each kW of

electric energy supplied, the water is heated by 15ŌĆō25 kW. Examples given below

include heaters, heat pumps and heat exchangers to illustrate the profitability

of using a composite heating system.

Example

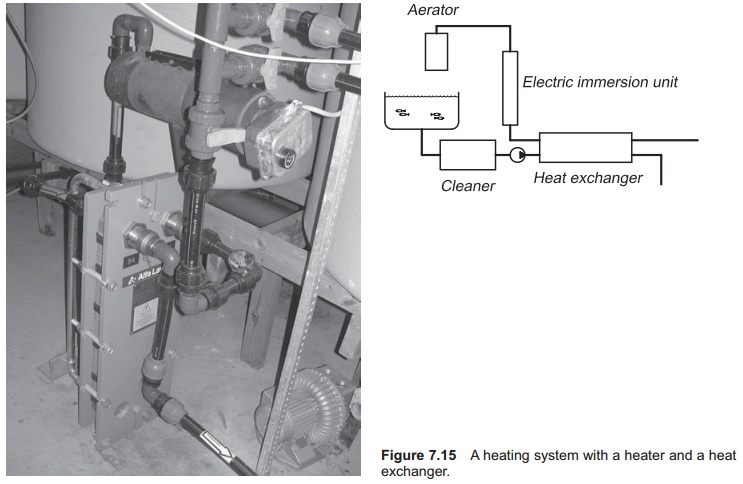

Heater and heat exchanger (Fig. 7.15)

Calculate the profitability of adding

a heat exchanger compared with using only an electric immersion heater in a

small heating system. A water flow of 180 l/min (3 l/s) is to be heated from 4 to 8┬░C. The first calculation is for an

electric heater alone.

Size of the heater:

P =mcpdt

= 3 l/s ├Ś 4.18 kJ/(kg ┬░C) ├Ś (8 ŌłÆ 4┬░C)

=50.2 kJ/s

=50.2 kW

The daily cost of using this system

with an electric-ity price of 0.1 Ōé¼/kWh is:

50.2 kW ├Ś 24 h ├Ś 0.1 Ōé¼/kWh = 120.5 Ōé¼

Now a heat exchanger is included in

the circuit to recover the energy in the outlet water; 75% recovery is quite

normal. This value of course depends on the cost of the heater, heat exchanger

and electricity; simu-lations should be done to find the most economical

combination. If 75% of the total heat increase above 4┬░C is provided by the

heat exchanger, 3┬░C of the temperature rise results from its use. This gives

the following temperatures in the heat exchanger as the same amount of water

flows on both sides:

Water entering heat exchanger 4┬░C

Water leaving heat exchanger 7┬░C

Water entering heater 7┬░C

Water leaving heater 8┬░C

A smaller heater is therefore needed

as the water is only going to be heated from 7 to 8┬░C:

P =3├Ś4.18├Ś(8ŌłÆ7)= 12.5 kW

This gives the following new daily

running costs:

12.5 ├Ś 24 ├Ś 0.1 = 30.0 Ōé¼

As can be seen, the daily cost of

heating is reduced from 120.5 to 30.0 Ōé¼, a saving of 90.5 Ōé¼ per day, by adding

a heat exchanger. This clearly illustrates the advantage of using a heat

exchanger.

The necessary size of the exchanger

will now be found.

Since the same amount of water is

circulating on both sides of the heat exchanger, it has the following

temperature programme:

Water entering heat exchanger 4┬░C

Water leaving heat exchanger 7┬░C

Water entering heater 7┬░C

Water leaving heater 8┬░C

The energy to be transferred from the

warm to the cold side in the heat exchanger given by

=

mcpdt

3 ├Ś 4.18 ├Ś 3

37.6 kJ/s

For a heat exchanger the following

equation applies:

P = kA LMTD

The k value for the plates in the

exchanger is set to 6 kW/(m2

┬░C) and the LMTD (temperature differ-ence that drives the heat transfer) is

1.0┬░C, which gives the following area:

=

P/(k LMTD)

=37.6/(6 ├Ś 1.0)

= 6.3 m2

Assuming a plate size of width 0.4 m

and height 1 m, the area is 0.4 m2 (this depends on the size of

plate supplied). The number of plates required = 6.3/0.4

= 15.8; this is an exchanger with 16 plates.

Example

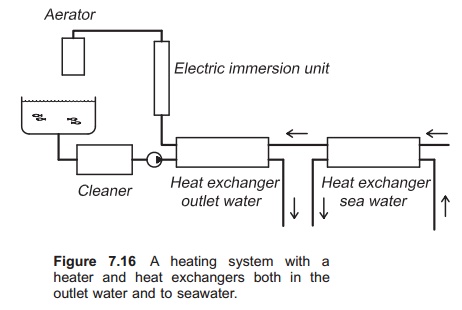

Heater with heat exchangers in outlet

water and in seawater (Fig. 7.16).

The inlet water has a temperature of

2┬░C and this is increased to 4┬░C when the water passes the seawater exchanger.

The water then enters an outlet exchanger where the temperature is further

increased to 9┬░C. The last increment up to 10┬░C, which is the temper-ature in

the fish tank, is supplied through an electric heater. Calculate the COP of the

system.

e = Qdeliverd/Qsupplied

= (ttankŌłÆtraw water)/(ttankŌłÆtbefore heater)

= (10 ŌłÆ 2)/(10 ŌłÆ 9)

= 8

The COP is 8 for this system, so that

for every kW of electric energy supplied 8 kW is supplied to the inlet water.

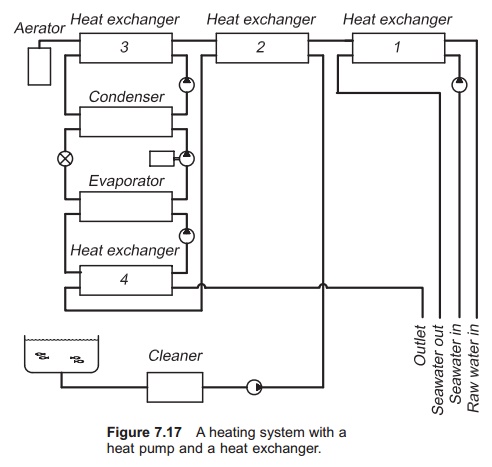

Example

Heat pump and heat exchanger (Fig.

7.17)

Find the profitability of installing

a heat pump, com-pared with a total energy system including a heat pump and

heat exchangers. A water flow of 300 l/min (50 l/s) is to be heated from 2 to 8┬░C. The heat pump has a COP of 5. How

much electric energy must be supplied?

First, the total amount of energy

that has to be trans-ferred to the water is calculated.

P =mcpdt

= 50 l/s ├Ś 4.18 kJ/(kg ┬░C) ├Ś (8 ŌłÆ 2┬░C)

= 1254 kJ/s

= 1254 kW

The COP is 5, meaning that the amount

of energy transferred to the compressor is

1254/5 = 250.8 kW

The daily cost of using a heat pump

with an elec-tricity price of 0.1 Ōé¼/kWh is therefore

250.8 kW ├Ś 24 h ├Ś 0.1 Ōé¼/kWh = 601.9 Ōé¼

Now a heat exchanger that recovers

the energy in the outlet water and transfers it to the inlet water is added to

the circuit. The heat exchanger is assumed to meet 75% of the heating

requirement. Of the total temperature increase of 6┬░C, 75% is provided by the

heat exchanger, i.e. 4.5┬░C, which gives the following temperatures in the heat

exchanger:

The new size of the heat pump can now

be calculated:

P =50├Ś4.18├Ś(8ŌłÆ6.5)

= 313.5 kW

With a COP of 5, the amount of energy

that must be supplied to the compressor is 313.5/5 = 62.7 kW. Therefore new daily costs are:

62.7 ├Ś 24 ├Ś 0.1 = 150.7 Ōé¼

As can be seen the daily cost of

heating is reduced from 601.9 Ōé¼ to 150.7 Ōé¼, a saving of 451.2 Ōé¼ per day, by

using a heat exchanger in addition to the heat pump. This illustrates how

useful it is to utilize a heat exchanger together with a heat pump. Heat pumps

are nearly always used together with one or several heat exchangers because of

the large reduction in energy costs compared to the investment costs of heat

exchangers.

The overall COP can now be

calculated:

e = total energy transferred to

thewater/electric energy supplied

= 1254 kW/62.7 kW

= 20.0

This means that of the total energy

transferred to the water, only 1/20 (5%) is supplied as electric energy.

Related Topics