Chapter: Aquaculture Engineering : Heating and Cooling

Construction and function of a heat pump

Construction and

function of a heat pump

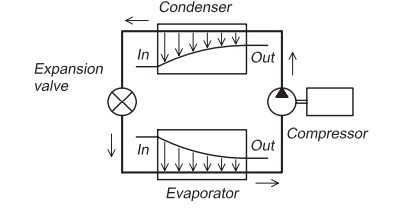

A heat pump consists of four main components (Fig. 7.12):

· Evaporator

· Compressor

· Condenser

· Expansion valve.

Between the four components there is a closed pipeline,

the transport circuit, in which the working medium or refrigerant circulates.

The medium is adapted so that it performs a phase transfer: it will change

phase between liquid and gas when circu-lating between the components in the

circuit. The system utilizes the energy needed for evaporation of the working

medium, which is released when the medium is condensed.

To explain the construction and function of the heat pump or refrigerator, the working medium can be followed for one lap round the closed pipeline circuit. When the medium enters the evaporator, it is a liquid of low temperature and with relatively low pressure. The boiling point of the medium is quite low. In the evaporator, which is actually a heat exchanger, the temperature is higher than in the working medium. Energy is therefore transferred from the surroundings and into the working medium, i.e. heat exchange occurs. The temperature increases up to the evaporation point for the working medium which starts to change phase from liquid to gas. When a medium changes from liquid to gas much energy is needed which is stored in the gas. The liquid–gas mix is then sucked into the compressor where the pressure increases together with the temperature so that all the medium is transformed into gas. The pressure in the working medium is now much higher than before.

The compressor is supplied with additional energy

(normally electricity) to function. Available compressors either use a piston

principle or the screw principle, the latter having continuous delivery of

gas. Not all the energy supplied to the compressor is transferred to the gas,

because there are some energy losses. The efficiency of a compressor is

normally about 70–80%, meaning that 70–80% of the added electricity is

transferred to the gas.

From the compressor the gas is pushed into the condenser

with the help of the created pressure. The condenser is another heat exchanger

where energy is transferred from the gas, which has the highest temperature,

into the surrounding water. The gas is now chilled and it reaches a temperature

where phase transfer occurs again, the dew point, and changes into liquid. The

evaporation energy that has been stored in the gas is now released and

transferred to the cold medium. The gas–liquid mix (or just the liquid,

depending on the construction and conditions) now flows to the expansion valve

where the pressure is reduced, for instance by increasing the cross-sectional

area of the pipe where the medium is flowing. The gas–liquid mix now expands.

(A simplification of this is that the liquid is pressed through a small hole

and out into a pipe with larger diameter.) All the medium now changes into

liquid. The pressure decrease of the medium is accompanied by a drop in

temperature. The working medium now enters the evaporator again and can then

start a new lap round the circuit; thus it circulates continuously.

The working medium or refrigerant must be adapted to the

temperature and pressure conditions in the evaporator and condenser. It must

evaporate and condense at temperatures that fit the temperature to which the

inlet water is to be heated, and of the water from which the heat is collected.

Neither must the pressure and pressure difference be too large. There has been

much discussion about refrigerants, because the most suitable have negative

effects on the environment by contributing to the greenhouse effect. New more

environmentally friendly refrigerants have there-fore been developed during the

past few years. In fish farming ammonia is much used, which is a relatively

environmentally friendly material regarding the greenhouse effect but highly

toxic for the fish, so it is important to avoid leakage of refrigerant into the

inlet water.

Related Topics