Chapter: civil : Design Of Steel Structures

Types Of Welded Connections

WELDED

CONNECCTION

INTRODUCTION

When two members are connected by

means of welds, such a connection is known as welded connection. Welding offers

an opportunity to the designer to achieve a more efficient use of the

materials. Earlier designers considered welds as less fatigue resistant. It was

believed that attaining good welds at site is impossible. Now a day, with the

advances in the field of non destructive testing methods (NDT), testing and

quality control of welds became easier. This gives the designers enough courage

to explore the possibilities and capabilities of welded connections. Speedy

construction is facilitated by using welded connections. Weight of welded

connections is relatively low and hence cuts cost of construction. Since there

is no reduction of holes the gross cross section is effective in carrying

loads.

TYPES OF WELDED CONNECTIONS

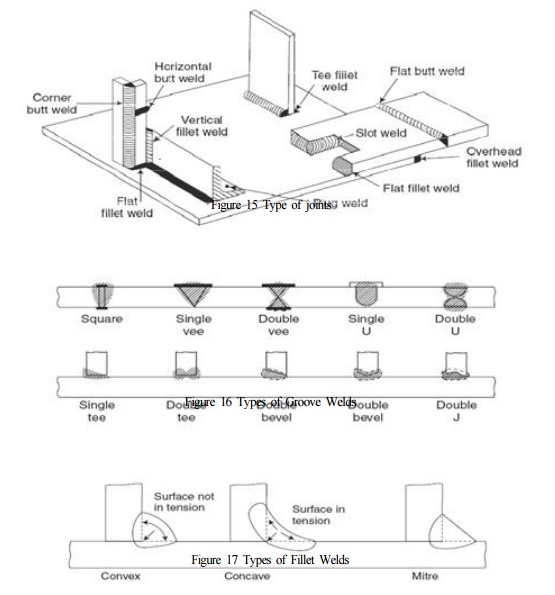

The basic types of welded joints

can be classified depending on the types of welds, position of welds and type

of joint.

1. Based

on the type of weld

Based on type of weld, welds can be classified in

to fillet weld, groove weld (or butt weld), plug weld, slot weld, spot weld

etc. Various types of welds are shown in Figure 15.

1.1.

Groove welds (butt welds)

Groove welds (butt welds) and

fillet welds are provided when the members to be joined are lined up. Groove

welds are costlier since it requires edge preparation. Groove welds can be

employed safely in heavily stressed members. Square butt welds are provided up

to a plate thickness of 8mm only. Various types of butt welds are shown in

Figure 16.

1.2.

Fillet welds

Fillet welds are provided when

two members to be jointed are in different planes. Since this situation occurs

more frequently, fillet welds are more common than butt welds. Fillet welds are

easier to make as it requires less surface preparation. Nevertheless, they are

not as strong as the groove welds and cause concentration of stress. Fillet

welds are preferred in lightly stressed members where stiffness rather than

strength governs the design. The various types of fillet welds are shown in

Figure 17.

1.3. Slot

and plug welds

Slot and plug welds are used to

supplement fillet welds where the required length of fillet weld cannot be

achieved.

2. Based

on the position of weld

Based on the position of weld,

welds can be classified in to flat weld, horizontal weld, vertical weld,

overhead well etc.

Based on

the type of joints

Based on

the type of joints, welds can be classified in to butt welded joints, lap

welded joints, tee welded joints and corner welded joints.

Related Topics