Chapter: civil : Design Of Steel Structures

Analysis And Design Of Fillet Welds

Analysis And Design Of Fillet Welds

ASSUMPTIONS IN THE ANALYSIS OF WELDED JOINTS

The following assumptions are made in the analysis of welded

joints.

• Welds

connecting various parts are homogeneous, isotropic and elastic.

• The

parts connected by welds are rigid and their deformations are therefore

neglected.

•

Only stresses due to external loads are

to be considered. Effects of residual stresses, stress concentrations and shape of welds

are neglected.

ANALYSIS

AND DESIGN OF FILLET WELDS

Fillet welds are provided for

connecting two members which are overlapping each other. Shear stresses are

usually the type of stress in the case of fillet welded connection. Direct

stresses to which the connections are subjected to are usually of lesser

importance. Concave fillet weld was favoured because it offers a smoother path

for the flow of stress. But concave fillet weld up on cooling shrinks and cause

tension to the surface which may cause cracks in the joint. On the other hand,

shrinkage of weld will cause compression in the case of convex fillet weld.

Concave fillet welds are more suitable under alternating stresses.

1. Size of Fillet weld

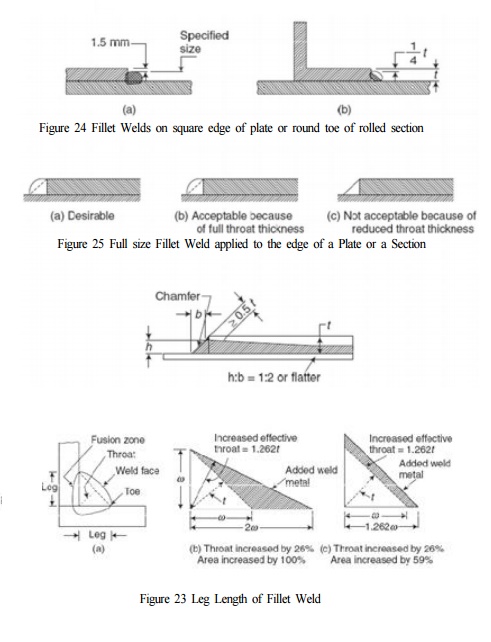

Cl.10.5.2.1 of IS800-2007 specifies the size of normal fillets

shall be taken as the minimum weld leg size. For deep penetration welds, where

the depth of penetration beyond the root run is a minimum of 2.4 mm, the size

of the fillet should be taken as the minimum leg size plus 2.4 mm. Figure 23

shows the leg length of fillet weld for various cases.

Cl.10.5.2.3 of IS800-2007

restricts minimum size of fillet welds to be 3 mm. The minimum size of the

first run or of a single run fillet weld shall be as given in Table 21 of IS800-2007,

to avoid the risk of cracking in the absence of preheating. Table 21 if

IS800-2007 is reproduced for ready reference as Table 6.

As per Cl.10.5.8.3 of IS800-2007,

where the size specified for a fillet weld is such that the parent metal will

not project beyond the weld, no melting of the outer cover or covers shall be

allowed to occur to such an extent as to reduce the throat thickness (see Fig.

18 of IS800:2007). The figure is reproduced here as Figure 25.

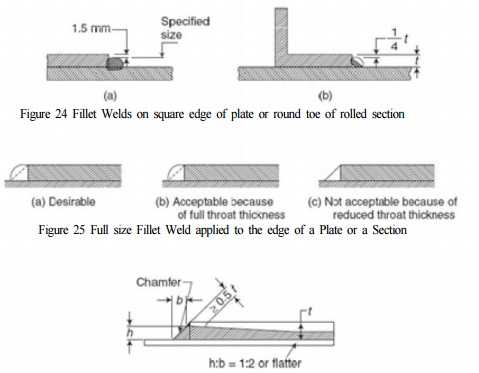

Cl.10.5.8.5 of IS800-2007

specifies for end fillet weld, normal to the direction of force shall be of

unequal size with a throat thickness not less than 0.5t, where t is the

thickness of the part, as shown

in Fig. 19 of IS800-2007. The

difference in thickness of the welds shall be negotiated at a uniform slope.

Fig. 19 of IS800-2007 is reproduced here as Figure 26.

Table 6

Minimum size of first run or of a single run fillet weld

SN Thickness of thicker part (mm)

Over Up

to and including - Minimum size (mm)

1 - 10 3

2 10 20 5

3 20 32 6

4 32 50 8

of 1st run, 10 for minimum weld size

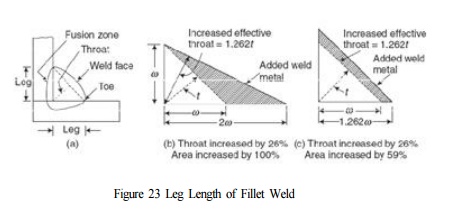

Cl.10.5.8 of IS800-2007 specifies the maximum size of fillet

weld applied to the edge of a plate

or section. Cl.10.5.8.1 specifies

where a fillet weld is applied to the square edge; the specified size of the

weld should generally beat least 1.5 mm less than the edge thickness (see Fig.

17A of IS800:2007). This figure is reproduced here as Figure 24(a).

Cl.10.5.8.2 of IS800-2007 gives the specification where the

fillet weld is applied to the rounded toe of a rolled section; the specified

size of the weld should generally not exceed 3/4 of the thickness of the

section at the toe (see Fig. 17B of IS800:2007). This figure is reproduced here

as Figure 24(b).

2. Effective throat thickness of fillet welds

Cl.10.5.3 of IS800-2007 gives the specification for Effective

Throat Thickness. Cl.10.5.3.1 specifies the effective throat thickness of a

fillet weld not to be less than 3 mm and shall generally not exceed 0.7t, or

1.0t under special circumstances, where t is the thickness of the thinner plate

of elements being welded. Further, Cl.10.5.3.2 of the code specifies the

effective throat thickness. For the purpose of stress calculation in fillet

welds joining faces inclined to each other, the effective throat thickness

shall be taken as K times the fillet size, where K is a constant, depending

upon the angle between fusion faces, as given in Table 22 of IS800-2007. Table

22 of IS800-2007 is reproduced here as Table 7 for ready reference.

Table

7 Values of K for different angles

Angle between fusion faces in degrees 60-90

91-100 101-106 107-113

114-120

Constant, K 0.70 0.65 0.60 0.55 0.50

3. Effective length of fillet welds

Effective Length of Weld is

considered in accordance with Cl.10.5.4 of IS800-2007. As per Cl.10.5.4.1, the

effective length of fillet weld shall be taken as only that length which is of

the specified size and required throat thickness. In practice the actual length

of weld is made of the effective length shown in drawing plus two times the

weld size, but not less than four times the size of the weld. So the effective

length of the weld is considered as actual length minus twice the weld size. As

per Cl.10.5.1.1, Fillet welds terminating at the ends or sides of parts should

be returned continuously around the corners for a distance of not less than

twice the size of the weld, unless it is impractical to do so. This is

particularly important on the tension end of parts carrying bending loads.

4. Effective area of fillet welds

The effective area of fillet

welds is obtained as the product of effective throat thickness and effective

length.

5. Design strength of fillet welds

Cl.10.5.7.1.1 of IS800-200 deals with the strength

of fillet welds. As detailed in this clause of the code, fillet welds shall be

designed based on the throat area (effective area). The code specifies the

design stress in the weld fwd= fwn/rmw

where and fwm is partial safety factor

of the material of the weld given by Table 5 of IS800-2007 and is the nominal stress of the material given

by fwn=Tdw=Lwtt . lu/31/2.rmw

is the ultimate stress of the material. Hence the design capacity of fillet

welds effective length of the weld is and ??is

the throat thickness.

6. Long joints

When the length of the welded joint, lj of a splice

or end connection in a compression or tension element is greater than 150 tt

the design capacity of weld, fwd shall be reduced by the factor ???1

7. Fillet weld subjected to individual stresses

Cl.10.5.9 of IS800:2007 specifies

the Stresses Due to Individual Forces. When subjected to either compressive or

tensile or shear force alone, the stress in the weld is given by FU/(3rmv)1/2

8. Fillet

welds subjected to combination of stresses

![]()

![]()

As per Cl.10.5.10.1.1, when

subjected to a

combination of normal

and shear stress,

the

equivalent stress fe shall satisfy the condition fa

=(fa2 +3q2)1/2 <=FU/(3rmv)1/2

Related Topics