Chapter: civil : Design Of Steel Structures : Introduction

Rolled Steel Sections

ROLLED

STEEL SECTIONS

Hot

Rolling is usually used to produce the standard section. In this process, the

molten steel is poured in to continuous casting systems where it is passed

through a series of rollers which squeeze it to the desired shape before if

solidifies completely. It is subsequently cut in to desired standard lengths.

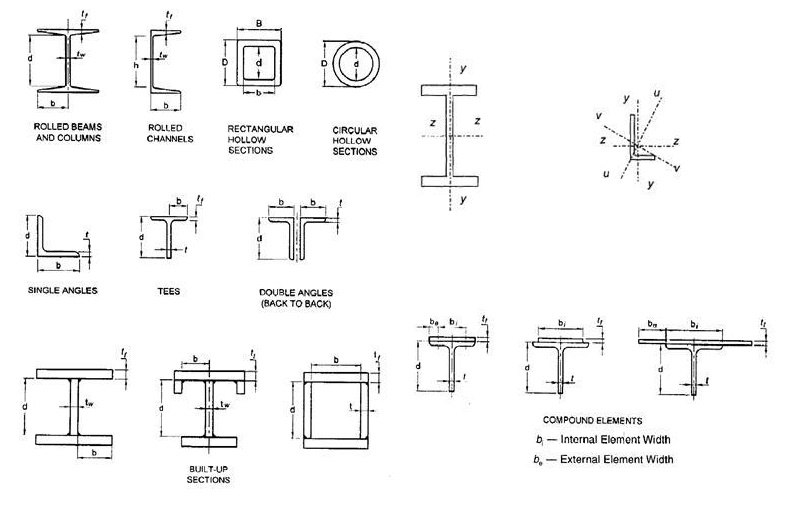

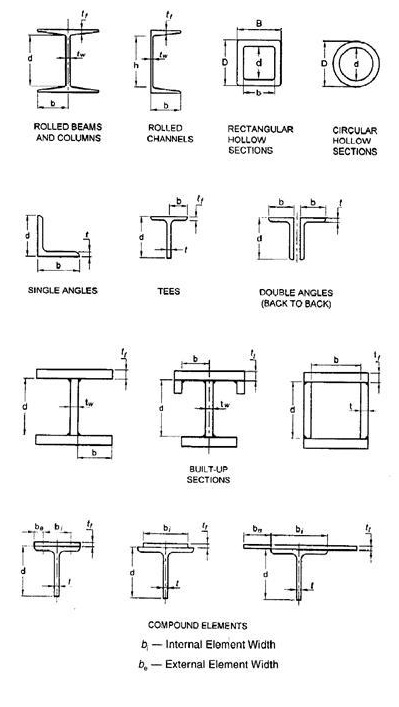

Cross section and size of the members are governed by optimum use of material,

functional requirement etc. Usually sections with larger modulus of section

compared to cross sectional area are preferred. IS Handbook 1 published by BIS

provides the dimensions, weights and other sectional properties of various

standard sections. Some of the sections as detailed by Figure 2 of IS 800:2007

is reproduced here in Figure 4.

Conventions

for member axes

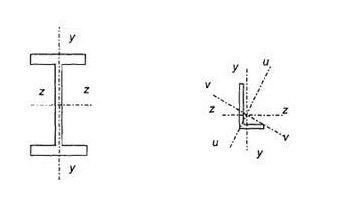

Unless

otherwise specified, x-x axis is considered along the length of the member; y-y

axis of the cross section is the axis perpendicular to the flanges in general

and the axis perpendicular to the smaller leg in the case of angles; z-z axis

of the cross section is the axis parallel to the flanges in general and the

axis parallel to the smaller leg in the case of angles; u-u axis is the major

axis of the section and v-v axis is the minor axis of the section. This is

schematically represented in Figure 5.

Related Topics