Chapter: civil : Design Of Steel Structures

Classification Of Bolts

BOLTED CONNECTIONS

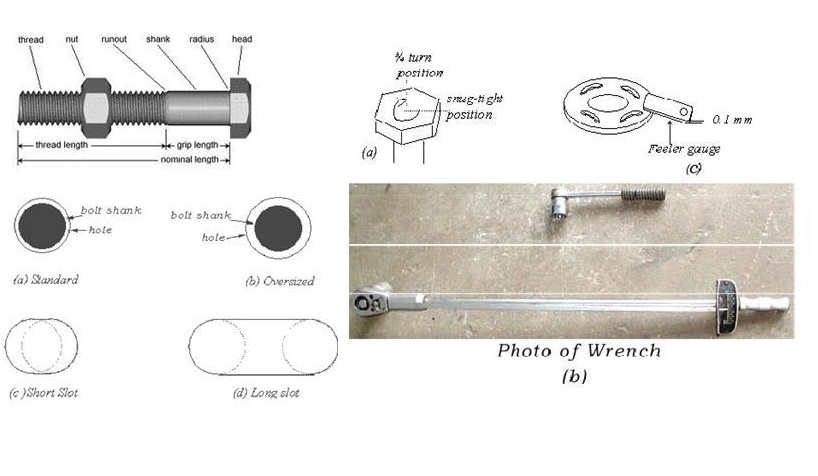

Bolt is a

metal pin with a head at one end and a shank threaded at other end to receive a

nut, as shown in Figure 6. Steel washers are usually provided under the bolt

head and nuts to prevent the treaded portion of the bolt from bearing on the

connecting pieces and to distribute the clamping pressure on the bolted member.

A bolt connection can be used for

end connections in tension and compression members. They can also hold down

column bases in position and as separator for purlins and beams in foundations.

Bolts are having the following advantages over rivets and pins: (a) the

erection of the structures can be speeded up. (b) Less skilled labour can be

employed. (c) Overall cost of bolted connection is lesser than the other

alternatives. However the following shortcomings are also associated with the

bolted connections: (a) Cost of material is high, about double than that of

rivets. (b) The tensile strength of bolt is reduced due to the reduced area at

the root of the thread and stress concentration. (c) Normally strength

reduction will be there for loose fit bolts. (d) Bolts may get loose when

subjected to vibrations.

CLASSIFICATION OF BOLTS

Bolts used in steel structures

are of three types:

1) Black Bolts

2) Turned and Fitted Bolts and

3) High Strength Friction Grip

(HSFG) Bolts.

The International Standards

Organisation designation for bolts, also followed in India, is given by Grade

x.y. In this nomenclature, x indicates one-tenth of the minimum ultimate

tensile strength of the bolt in kgf/mm2 and the second number, y,

indicates one-tenth of the ratio of the yield stress to ultimate stress,

expressed as a percentage. Thus, for example, grade 4.6 bolt will have a

minimum ultimate strength 40 kgf/mm2 (392 MPa) and minimum yield

strength of 0.6 times 40, which is 24 kgf/mm2 (235 MPa).

5.1.1. Black bolts

Black bolts are unfinished and

are made of mild steel and are usually of Grade 4.6. Black bolts have adequate

strength and ductility when used properly; but while tightening the nut snug

tight ('Snug tight'

is defined as the tightness that exists when all plies in a joint are

in firm contact) will twist off

easily if tightened too much.

5.1.2. Turned and fitted bolts

Turned and fitted bolts have uniform shanks and are inserted

in close tolerance drilled holes and made snug tight by box spanners. The

diameter of the hole is about 1.5 to 2.0 mm larger than the bolt diameter for

ease in fitting. High strength black bolts (grade 8.8) may also be used in

connections in which the bolts are tightened snug fit. In these bearing type of

connections, the plates are in firm contact but may slip under loading until

the hole surface bears against the bolt .The load transmitted from plate to

bolt is therefore by bearing and the bolt is in shear. Under dynamic loads, the

nuts are liable to become loose and so these bolts are not allowed for use

under such loading. In situations where small slips can cause significant

effects as in beam splices, black bolts are not preferred. However, due to the

lower cost of the bolt and its installation, black bolts are quite popular in

simple structures subjected to static loading. Turned and fitted bolts are

available from grade 4.6 to grade 8.8. For the higher grades there is no

definite yield point and so 0.2% proof stress is used.

5.1.3. High Strength Friction Grip bolts (HSFG)

High Strength Friction Grip bolts

(HSFG) provide extremely efficient connections and perform well under

fluctuating/fatigue load conditions. These bolts should be tightened to their

proof loads and require hardened washers to distribute the load under the bolt

heads. The washers are usually tapered when used on rolled steel sections. The

tension in the bolt ensures that no slip takes place under working conditions

and so the load transmission from plate to the bolt is through friction and not

by bearing. However, under ultimate load, the friction may be overcome leading

to a slip and so bearing will govern the design. HSFG bolts are made from

quenched and tempered alloy steels with grades from 8.8 to 10.9. The most

common are the so-called, general grade of 8.8 and have medium carbon content,

which makes them less ductile. The 10.9 grade have a much higher tensile

strength, but lower ductility and the margin between the 0.2% yield strength

and the ultimate strength is also lower. The tightening of HSFG bolts can be

done by either of the following methods (IS 4000):

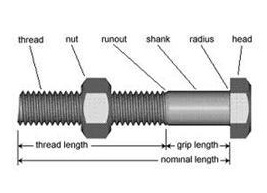

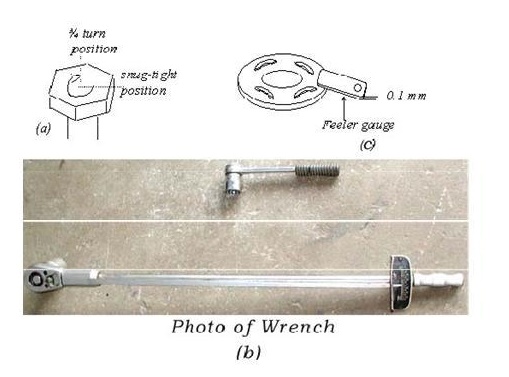

• Turn-of-nut

tightening method: In this method the bolts are first made snug tight and then

turned

by specific amounts (usually either half or three-fourth turns) to induce

tension equal to the proof load (Figure 7(a)).

•

Calibrated wrench tightening method: In

this method the bolts are tightened by a wrench

(Figure 7(b)) calibrated to produce the required tension.

• Alternate

design bolt installation: In this method special bolts are used which indicate

the bolt

tension. Presently such bolts are not available in India.

• Direct tension indicator

method: In this method special washers with protrusions are used

(Figure

7(c)). As the bolt is tightened, these protrusions are compressed and the gap

produced by them gets reduced in proportion to the load. This gap is measured

by means of a feeler gauge, consisting of small bits of steel plates of varying

thickness, which can be inserted into the gap.

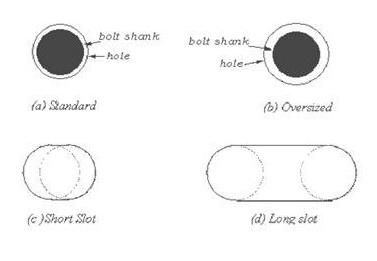

Since

HSFG bolts under working loads, do not rely on resistance from bearing, holes

larger than usual can be provided to ease erection and take care of

lack-of-fit. Typical hole types that can be used are standard, extra large and

short or long slotted. These are shown in Figure 8. However the type of hole

will govern the strength of the connection. Holes must also satisfy pitch and

edge/end distance criteria (Cl.10.2 of IS 800:2007). A minimum pitch is usually

specified for accommodating the spanner and to limit adverse interaction

between the bearing stresses on neighbouring bolts. A maximum pitch criterion

takes care of buckling of the plies under compressive loads.

Related Topics