Chapter: Mechanical : Robotics : Robot Drive Systems and End Effectors

Two and Three-fingered gripper

Two

and Three-fingered gripper

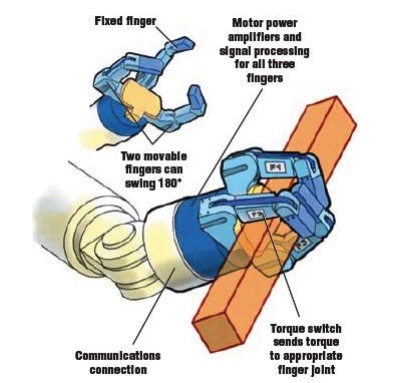

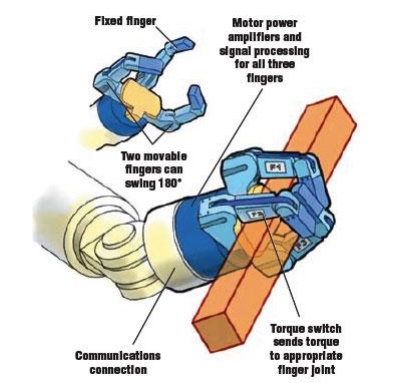

Three-fingered gripper

It's also costly to

order custom-made handlers for special parts. To solve these problems,

engineers at Barrett Technology Inc., Cambridge, Mass. (barrett.com),

developed the Barrett Hand, a three-fingered gripper that can securely hold a

wide variety of shapes and parts.

The

device has three articulated fingers. The center finger is fixed, and the other

two

rotate up to 180˚ around the outside of grips and configurations. Each finger

has two sections which act in concert to grab objects.

When the first section touches an object, the second

section continues retracting until it is also in contact. With all the fingers

in play, and including the palm, the hand can have a seven-point grip on the

object. This lets it deal with objects of unknown or inconsistent shapes. The

hand can lift about 1.2 kg.

The hand's eight joints are controlled by four

brushless-dc motors, all in the wrist section. A torque switch lets four motors

control eight axes of motion. The gripper's communications, five

microprocessors, sensors, and signal processor are packed inside the palm body.

A small umbilical cable connects the hand to an array of robotic arms from

different manufacturers.

Two-fingered gripper

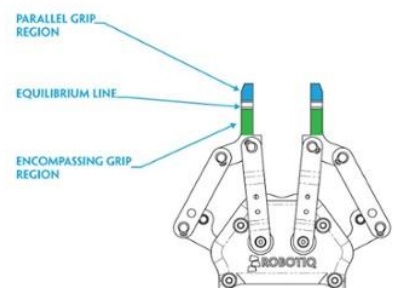

The mechanism driving the fingers of this Gripper is

optimized to obtain two distinct contact regions. The first one, ca base of the

fingers, while the second one, end/tip. The boundary between these two adjacent

regions is called t

When the contact of the finger with the object to be

grasped occurs in the encompassing grip region, the finger automatically adapts

to the shape of the object and curls around it. On the other hand, when the

contact is made in the pinch grip region, the finger maintains its parallel

motion and the object is pinched.

Since the finger keeps its parallel motion when a

contact is made above the equilibrium point during a pinch grip, the same is

true for a contact made below the equilibrium point during an inside grip, i.e.

for a force applied at the back of the finger. This unique feature allows the

Gripper to pick up objects from the inside, which proves to be very useful in

many situations.

Coupling between the

fingers

In addition to the

mechanism used inside each of its fingers, the Gripper also relies on a special

coupling architecture between the fingers. In fact, it is mechanically designed

to ensure that the two fingers move in conjunction with each other in order to

center the object grasped in the middle of the Gripper. This self-centering

avoids the need to use expensive sensor sand is above all safer.

In the same vein to

make this Robot Gripper as reliable as possible, a self-locking feature has

been incorporated into it between the actuator and the fingers. By doing so, we

are sure that the Gripper will never release the object and let it fall if the

power is shut down. It is also

economically interesting, ase continually the when actuatoran

object do is grasped, thus in addition to the power saved, the lifespan of the

Gripper is thereby maximized.

Related Topics