Chapter: Mechanical : Robotics : Robot Drive Systems and End Effectors

Grippers

Grippers

In robotics, an end effector is the device at the

end of a robotic arm, designed to interact

with the environment. The exact nature of this device depends on the

application of the robot.In the strict definition, which originates from serial

robotic manipulators, the end effector

means the last link (or end) of the robot. At this endpoint the tools are attached. In a wider

sense, an end effector can be seen as the part of a robot that interacts with

the work environment. This does not refer to the wheels of a mobile robot or the feet of ahumanoid robot which are also not

end effectors—they are part of the robot's mobility.

End

effectors may consist of a gripper or a tool. When referring to robotic

prehension there are four general categories of robot grippers, these are:

1.

Impactive –jaws or claws which

physically grasp by direct impact upon the object.

2.

Ingressive –pins, needles or hackles

which physically penetrate the surface of the object (used in textile, carbon

and glass fibre handling).

3.

Astrictive –suction [vague]

forces applied to the objects surface (whether by vacuum, magneto- or electroadhesion).

4.

Contigutive –requiring direct contact

for adhesion to take place (such as glue, surface tension or freezing).

They are based on different physical effects used to

guarantee a stable grasping between a gripper and the object to be grasped.

Industrial grippers can be mechanical, the most diffused in industry, but also

based on suction or on the magnetic force. Vacuum cups and electromagnets

dominate the automotive field and in particular metal sheet handling. Bernoulli

grippers exploit the airflow between the gripper and the part that causes a

lifting force which brings the gripper and part close each other (i.e. the Bernoulli's principle). Bernoulli

grippers are a type of contactless grippers, namely the object remains confined

in the force filed generated by the gripper without coming into direct contact

with it. Bernoulli gripper is adopted in Photovoltaic cell handling in silicon wafer handling but also in

textile or leather industry. Other principles are less used at the macro scale

(part size >5mm), but in the last ten years they demonstrated interesting

applications in micro-handling.

A gripper is a motion device that mimics the

movements of people, in the case of the gripper, it is the fingers. A gripper

is a d evice that holds an object so it can be manipulated. It has the ability

to hold and release an object while some action is being performed. The fingers

are not part of the gripper, they are specialized custom tooling used to grip

the object and are referred to as "jaws." Two main types of action

are performed by grippers:

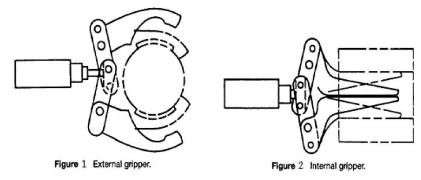

External:

This

is the most popular method of holding objects, it is the most simplistic and it

requires the shortest stroke length. When the gripper jaws close, the

closing force of the gripper holds that object.

Related Topics