Chapter: Mechanical : Robotics : Robot Drive Systems and End Effectors

DC Servo Motors | Stepper Motor

DC Servo Motors | Stepper Motor

Under Electrical Motor

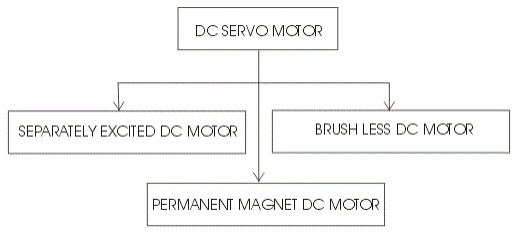

As we know that any electrical motor can be utilized as servo motor if it is controlled by

servomechanism. Likewise, if we control a

DC motor by means of servomechanism, it would be referred as DC servo

motor. There are different types of

DC motor, such shunt wound DC motor, series DC motor,

Separately excited DC motor,

permanent magnet DC motor,

Brushless DC motor etc. Among all mainly separately excited DC motor, permanent

magnet DC motor and brush less DC motor are used as servo.

DC Servo Motor

The motors which are

utilized as DC servo motors, generally have separate DC source for field

winding and armature winding. The control can be archived either by controlling

the field current or armature current.

Field control has some specific advantages over armature control and on the

other hand armature control has also some specific advantages over field

control. Which type of control should be applied to the DC servo motor, is

being decided depending upon its specific applications. Let's discus DC servo

motor working principle for field control and armature control one by one.

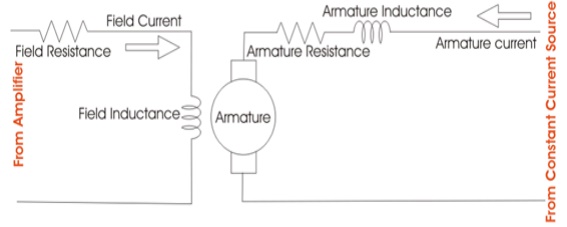

Field Controlled DC Servo Motor

The figure below illustrates

the schematic diagram for a field controlled DC servo motor. In this

arrangement the field of DC motor is

excited be the amplified error signal and armature winding is energized by a

constant current source .

The field is controlled below

the knee point of magnetizing saturation curve. At that portion of the curve

the mmf linearly varies with excitation current. That means torque developed in

the DC motor is directly proportional to

the field current below the knee point

of magnetizing saturation curve From general

torque equation of DC motor it is found that, torque T ∝φIa. Where, φ isaarmaturefieldcurrent.

fluxButinfield controlledand IDC servo motor, the armature is excited by

constant current source , hence Ia is

constan.

The DC Stepper Motor

Like the DC motor above,

Stepper Motors are also electromechanical actuators that convert a pulsed

digital input signal into a discrete (incremental) mechanical movement are used

widely in industrial control applications. A stepper motor is a type of

synchronous brushless motor in that it does not have an armature with a

commutator and carbon brushes but has a rotor made up of many, some types have

hundreds of permanent magnetic teeth and a stator with individual windings.

As it name implies, the

stepper motor does not rotate in a continuous fashion like

a conventional DC motor

but moves in discret rotational movement or step dependant upon the number of

stator poles and rotor teeth the stepper motor has.

Because of their discrete

step operation, stepper motors can easily be rotated a finite fraction of a

rotation at a time, such as 1.8, 3.6, 7.5 degrees etc. So for example, lets

assume that a stepper motor completes one full revolution (360o in exactly 100

steps.

Then the step angle for

the motor is given as 360 degrees/100 steps = 3.6 degrees per step. This value

is commonly known as the stepper motors Step Angle.

There are three basic

types of stepper motor, Variable Reluctance, Permanent Magnet andHybrid (a sort

of combination of both). A Stepper Motor is particularly well suited to

applications that require accurate positioning and repeatability with a fast

response to starting, stopping, reversing and speed control and another key

feature of the stepper motor, is its ability to hold the load steady once the

require position is achieved.

Generally, stepper motors

have an internal rotor with a large number of permanent h”magnetwith

“teetanumber of electromagnet stators electromagnets are polarized and

depolarized sequentially, causing the rotor to rotate one

“step” at a time.

Modern multi-pole,

multi-teeth stepper motors are capable of accuracies of less than 0.9 degs per

step (400 Pulses per Revolution) and are mainly used for highly accurate

positioning systems like those used for magnetic-heads in floppy/hard disc

drives, printers/plotters or robotic applications. The most commonly used

stepper motor being the 200 step per revolution stepper motor. It has a 50

teeth rotor, 4-phase stator and a step angle of 1.8 degrees (360 degs/(50×4)).

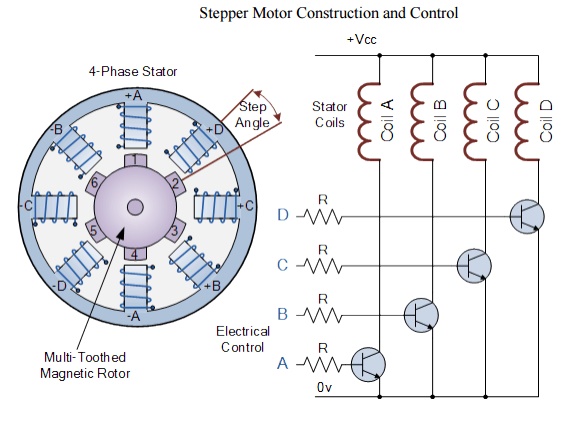

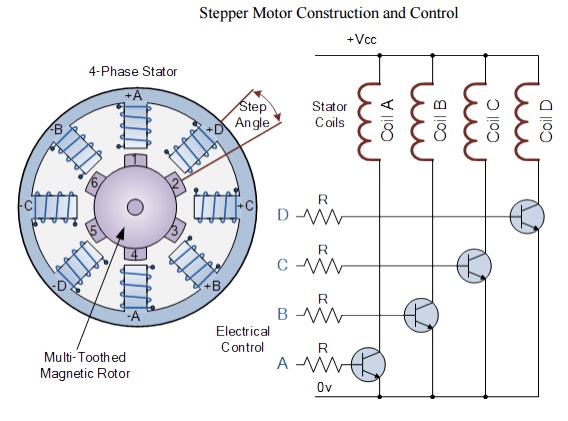

Stepper Motor Construction and Control

In our simple example of a

variable reluctance stepper motor above, the motor consists of a central rotor

surrounded by four electromagnetic field coils labelled A, B, C and D.

All the

coils with the same

letter are connected together so

that energising, say

coils marked A will cause the magnetic rotor to align itself with that

set of coils.

By applying power to each

set of coils in turn the rotor can be made to rotate or "step" from

one position to the next by an angle determined by its step angle construction,

and by energising the coils in sequence the rotor will produce a rotary motion.

The stepper motor driver

controls both the step angle and speed of the motor by energising the field

coilsADCB,in ADCB,aset”ADCB,setc,quencAth… rotor will rotate in one direction

(forward) and by reversing the pulseABCD, seq ABCD, ABCD,”etc,A… the rotor will

rotate in the

So in our simple example

above, the stepper motor has four coils, making it a 4-phase motor, with the

number of poles on the stator being eight (2 x 4) which are spaced at 45 degree

intervals. The number of teeth on the rotor is six which are spaced 60 degrees

apart.

Then there are 24 (6 teeth

x 4 coils) complete one full revolution. Therefore, the step angle above is

given as: 360o/24 = 15o.

Obviously, the more rotor

teeth and or stator coils would result in more control and a finer step angle.

Also by connecting the electrical coils of the motor in different

configurations, Full, Half and micro-step angles are possible. However, to

achieve micro-stepping, the stepper motor must be driven by a (quasi)

sinusoidal current that is expensive to implement.

It is also possible to

control the speed of rotation of a stepper motor by altering the time delay

between the digital pulses applied to the coils (the frequency), the longer the

delay the slower the speed for one complete revolution. By applying a fixed

number of pulses to the motor, the motor shaft will rotate through a given

angle.

The advantage of using

time delayed pulse is that there would be no need for any form of additional

feedback because by counting the number of pulses given to the motor the final

position of the rotor will be exactly known. This response to a set number of

digital input pulses allows the stepper motor to operate i cheaper to control.

Related Topics