Chapter: Mechanical : Robotics : Robot Drive Systems and End Effectors

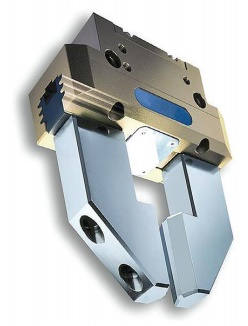

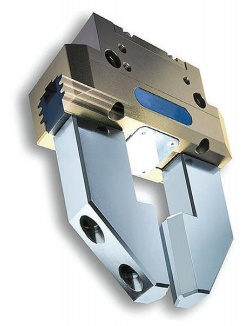

Hydraulic Grippers

Hydraulic

Grippers

Grippers

are devices used with pick-and-place robotic systems to pick up or place an

object on an assembly line, conveyor system, or other automated system.

Fingered tooling—or jaws—is attached to the grippers to grip or hold the

object.

They come in a variety of styles and powered

designs. Three common types are parallel, three-finger, and angled designs. The

most common are parallel designs, with two fingers that close on a workpiece to

grip it or open it out by creating pressure on the inside. Three-finger designs

hold the workpiece in the center, and have three fingers offset by 120°.

Finally, angled designs feature jaws that work at a variety of different angle

openings (for example, 30°, 40°, etc.).

In addition, three choices of power are available;

the most common being pneumatic grippers; electromechanical grippers are second

most common; and the least common being hydraulic grippers. Hydraulic grippers

are most often used in conjunction with a piece of equipment that only has a hydraulic

power source for actuators.

Most hydraulic grippers are designed for a hydraulic

system where the cylinder diameter is made with less surface area, meaning that

a hydraulic gripper would have the same force at 60 bar as a pneumatic gripper

of the same size at 6 bar.

In general, hydraulic and pneumatic grippers have

the same basic actuation principle. They include direct acting piston designs

as well as piston wedge designs.

The

direct acting piston design is used when a hydraulic force acts directly on a

piston that is directly connected to the jaw or finger that is touching or

gripping the part.

The

piston wedge design features a hydraulic force acting on a piston while the

piston itself is acting on a wedge. The wedge translates this force to the jaws

or fingers, providing the grip force to grip the part. The wedge can give a

mechanical advantage as it can increase grip force while keeping the piston

diameter and pressure to the piston the same. This allows more grip force in a

smaller package compared to the directing piston.

Unlike electromechanical grippers, which have motors

on each actuator, one single motor powers the hydraulic fluid that supplies

energy to multiple devices throughout a plant.When selecting a hydraulic

gripper, it is important to consider the following:

·

Part weight and size to be lifted

·

Part material

·

Clearance issues around the part that

could interfere with the gripping part

·

The environment the gripper will be used

in (corrosive, food or beverage, etc.)

·

The motion path of the robot or linear

device that is moving the gripper

·

The power supply that will be available

and the pressure ratings available

Related Topics