Chapter: Mechanical : Robotics : Robot Drive Systems and End Effectors

Pneumatic actuators system

Pneumatic actuators system

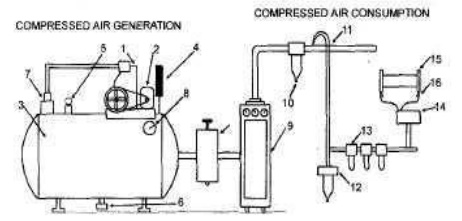

Pneumatic systems use pressurized air to make things move. Basic pneumatic system consists

of an air generating unit and an air-consuming unit.

Air compressed in compressor is not ready for

use as such, air has to be

filtered, moisture present in air

has to be dried, and for different applications in plant pressure of air has to be varied.

Several other

treatments are given

to the air

before it reaches

finally to the

Actuators. Practically

some accessories are

added for economical

and efficient

operation

of system.

Compressor:

A device, which

converts mechanical force and motion into pneumatic fluid power, is called

compressor.

Every

compressed-air system begins with a compressor, as it is the source of

airflow

for all the downstream equipment and processes Electric Motor Electric motor

is

used to drive the compressor.

Pressure

Switch:

Pressure Switch is used

to maintain the required pressure in the receiver; it adjusts the High Pressure

Limit and Low Pressure Limit in the receiver.The compressor is automatically

turned off when the pressure is about to exceed the high limit and it is also

automatically turned on when the pressure is about to fall below the low limit.

Safety

Valve:

The function of the

safety valve is to release extra pressure if the pressure inside the receiver

tends to exceed the safe pressure limit of the receiver.

Check

Valve:

The valve enables flow

in one direction and blocks flow in a counter direction is called Check Valve.

Once compressed air

enters the receiver via check valve, it is not allowed to go back even when the

compressor is stopped.

Direction

Control Valve:

Directional-control

valve are devices used to change the flow direction of fluid within a

Pneumatic/Hydraulic circuit.

They control

compressed-air flow to cylinders, rotary actuators, grippers, and other

mechanisms in packaging, handling, assembly, and countless other applications.

These valves can be actuated either manually or

electrically.

Pneumatic

Actuator:

A device in which power

is transferred from one pressurized medium to another without intensification.

Pneumatic actuators are normally used to control

processes requiring quick and accurate response, as they do not require a large

amount of motive force. They may be reciprocating cylinders, rotating motors or

may be a robot end effectors.

Related Topics