Chapter: Mechanical : Robotics : Robot Drive Systems and End Effectors

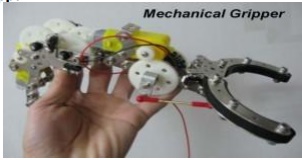

Mechanical Gripper

Mechanical Gripper

A mechanical gripper is used as an end effector

in a robot for grasping the objects with its mechanically operated

fingers. In industries, two fingers are enough for holding purposes. More than

three fingers can also be used based on the application. As most of the fingers

are of replaceabletype, it can be easily removed and replaced.

A

robot requires either hydraulic, electric, or pneumatic drive system to create

the input power. The power produced is sent to the gripper for making the

fingers react. It also allows the fingers to perform open and close actions.

Most importantly, a sufficient force must be given to hold the object.

In a mechanical

gripper, the holding of an object can be done by two different methods

such as:

·

Using the finger pads as like the shape

of the work part.

·

Using soft material finger pads.

In the first method, the contact surfaces of the

fingers are designed according to the work part for achieving the estimated

shape. It will help the fingers to hold the work part for some extent.

In the second method, the fingers must be capable of

supplying sufficient force to hold the work part. To avoid scratches on the

work part, soft type pads are fabricated on the fingers. As a result,

the contact surface of the finger and co –efficient of friction are improved.

This method is very simple and as well as less expensive. It may cause

slippage if the force applied against the work part is in the parallel

direction. The slippage can be avoided by designing the gripper based on the

force exerted.

µ nf Fg = w …………………

1 µ => co –efficient of friction between the work part and

fingers

nf

=> no. of fingers contacting Fg => Force of the gripper

w => weight of the

grasped object

The

equation 1 must be changed if the weight of a work part is more than the

force applied to cause

the slippage.

µ nf Fg = w g …..…………….2

g => g factor

During rapid grasping operation, the work part will

get twice the weight. To get rid out of it, the modified equation 1 is

put forward by Engelberger. The g factor in the equation 2 is used to

calculate the acceleration and gravity.

The values of g

factor for several operations are given below:

§ g

= 1 –acceleration supplied in the opposite direction.

§ g

= 2 –acceleration supplied in the horizontal direction.

§ g

= 3 –acceleration and gravity supplied in the same direction.

A

pneumatic gripper is a specific type of pneumatic actuator that typically

involves either parallel or angular motion of surfaces, A.K.

When

combined with other pneumatic, electric, or hydraulic components, the gripper

can be used as part of a "pick and place" system that will allow a

component to be picked up and placed somewhere else as part of a manufacturing

system.

Some

grippers act directly on the object they are gripping based on the force of the

air pressure supplied to the gripper, while others will use a mechanism such as

a gear or toggle to leverage the amount of force applied to the object being

gripped. Grippers can also vary in terms of the opening size, the amount of

force that can be applied, and the shape of the gripping surfaces— frequently

called "tooling jaws or fingers". They can be used to pick up

everything from very small items (a transistor or chip for a circuit board, for example) to very

large items, such as an engine block for a car. Grippers

are frequently added to industrial robots in order to allow the robot to

interact with other objects.

Common industrial

pneumatic components include:

· pneumatic direct

operated solenoid valve

·

pneumatic pilot operated solenoid valve

·

pneumatic external piloted solenoid

valve

·

pneumatic manual valve

·

pneumatic valve with air pilot actuator

·

pneumatic pressure regulator

Related Topics