Chapter: Mechanical : Robotics : Robot Drive Systems and End Effectors

Introduction Robot Drive Systems

Introduction

Robot Drive Systems

The actions of the individual joints

must be controlled in order for the manipulator to perform a

desired move its body, arm, motion and wrist. The is provided by the drive system

used to power the robot.

The joints are moved by actuators

powered by a particular form of drive system.

Common drive systems used in robotics

are electric drive, hydraulic drive, and pneumatic drive.

Types of Actuators

*Electric Motors, like:

Servomotors, Stepper motors

or Direct-drive electric motors

*Hydraulic actuators

*Pneumatic actuators

Ø

Mechanical Drive Systems

The drive system determines the speed

of the arm movement, the strength of the robot, dynamic performance, and, to

some extent, the kinds of application.

A robot will require a drive system

for moving their arm, wrist, and body. A drive system is usually used to

determine the capacity of a robot. For actuating the robot joints, there are three

different types of drive systems available such as:

(i)

Electric drive system,

(ii)

Hydraulic drive system,

and

(iii) Pneumatic drive system.

The most

importantly used two types of drive systems are electric and hydraulic.

(i)

Electric Drive System:

The electric drive systems are capable

of moving robots with high power or speed. The actuation of this type of

robot can be done by either DC servo motors or DC stepping motors. It can be

well –suited for rotational joints and as well as linear joints. The electric

drive system will be perfect for small robots and precise applications.

Most importantly, it has got greater accuracy and repeatability. The one

disadvantage of this system is that it is slightly costlier. An example for

this type of drive system is Maker 110 robot.

Ø

Hydraulic Drive System:

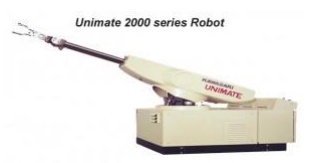

The hydraulic drive systems are completely meant for the large –sized robots. It can deliver high power or speed than the electric drive systems. This drive system can be used for both linear and rotational joints. The rotary motions are provided by the rotary vane actuators, while the linear motions are produced by hydraulic pistons. The leakage of hydraulic oils is considered as the major disadvantage of this drive. An example for the hydraulic drive system is Unimate 2000 series robot.

The pneumatic drive systems are especially used for the small type robots, which have less than five degrees of freedom. It has the ability to offer fine accuracy and speed. This drive system can produce rotary movements by actuating the rotary actuators. The translational movements of sliding joints can also be provided by operating the piston. The price of this system is less when compared to the hydraulic drive. The drawback of this system is that it will not be a perfect selection for the faster operations.

Related Topics