Chapter: Mechanical : Robotics : Robot Drive Systems and End Effectors

Mechanical drives system

Mechanical

drives system

When the various

driving methods like hydraulic, pneumatic, electrical servo motors and stepping

motors are used in robots, it is necessary to get the motion in linear or

rotary fashion.

When motors are used,

rotary motion is converted to linear motion through rack and pinion gearing,

lead screws, worm gearing or bail screws.

Rack

and Pinion Movement:

The pinion is in mesh

with rack (gear of infinite radius). If the rack is fixed, the pinion will

rotate. The rotary motion of the pinion will be converted to linear motion of

the carriage.

Ball

Screws:

Sometimes lead screws

rotate to drive the nut along a track. But simple lead screws cause friction

and wear, causing positional inaccuracy.

Therefore ball bearing

screws are used in robots as they have low friction. The balls roll between the

nut and the screw. A cage is provided for recirculation of the balls. The

rolling friction of the ball enhances transmission efficiency to about 90%.

Gear

Trains:

Gear trains use spur,

helical and worm gearing. A reduction of speed, change of torque and angular

velocity are possible. Positional errors are caused due to backlash in the

gears.

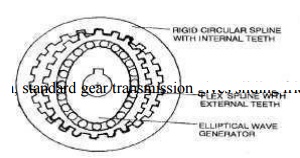

Harmonic Drive:

For

speed reduction, standard gear transmission gives sliding friction and

backlash.

Moreover,

it takes more space.

Harmonic drive due to

its natural preloading eliminates backlash and greatly reduces tooth wear.

Harmonic drives are suitable for robot

drives due to their smooth and efficient action. The circular spline is a rigid

ring with gear teeth machined on the inside diameter.

The

flex spline is a flexible ring with the teeth cut on its outside diameter.

The flex spline has

fewer teeth (say 2 teeth less) than the circular spline. The wave generator is

elliptical and is given input motion.

Wave generator and flex

spline is placed into the circular spline such that the outer tooth of flex

spline is in mesh with the internal teeth of circular spline.

If the circular spline

has 100 teeth and the flex spline has 98 teeth, and if the wave generator makes

one complete revolution, the flex spline will engage 98 teeth of the circular

spline.

Since circular spline

has 100 teeth and only 98 teeth have been in engagement for one complete

rotation, the circular saline's position has been shifted by 2 teeth.

Thus after 50

revolutions of the wave generator, the circular spline will have made one full

rotation. The ratio of harmonic drive is 2: 100 or 1: 50.

The gear ratio is influenced by the number of teeth

cut into the circular spline and the flex spline. The harmonic drive has high

torque capacity.

Related Topics