Chapter: Mechanical : Maintenance Engineering : Maintenance Policies and Preventive Maintenance

Scheduling Techniques: Critical Path Method

Scheduling

Techniques

Scheduling

is one of the areas that received considerable attention from researchers as well

as practitioners in all types of applications including operations scheduling

and project scheduling. Techniques are developed to develop optimum or near

optimal schedules with respect to different possible performance measures. This

chapter highlights some of these techniques and their application in

maintenance scheduling.

Critical

Path Method

To identify

the critical path

using the CPM

method we need

to follow the following steps:

1.

Develop the project network diagram as shown in

the previous section;

2. Perform

the CPM calculation to identify the critical jobs (there are jobs on the

critical paths and non-critical jobs (which are jobs with float);

3.

Perform

project crashing to

(determine minimum times

for each job)

reduce

project duration and investigate the cost tradeoffs; and

4. Level the resources in order

to have uniform manpower requirements to minimize hiring, firing, or overtime

requirements.

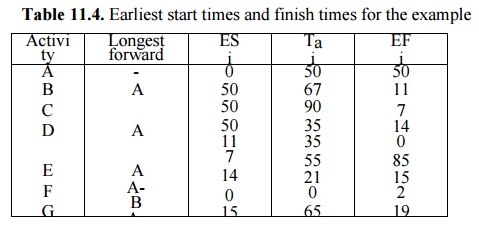

The critical path calculation includes two phases. The first

phase is the forward pass (starting with the first node and proceeding to the

last node). In this phase, the earliest start time, ES, and earliest finish

time, EF, are determined for each activity. The earliest start time ESi for a

given activity, i, is the earliest possible time in the schedule that activity

i can be started. Its value is determined by summing up the activity times of

the activities lying on the longest path leading to it. The earliest finish

time EFi for a given activity i, is its earliest start time plus its activity

time Tai. The calculations for the

bearing overhaul example are shown in Table 11.4.

Table 11.4. Earliest start times and finish

times for the example

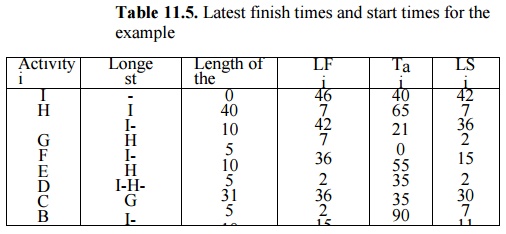

The second phase is the backward pass (starting with the last

node and proceeding back to the first node). We start this phase by assuming

that the total project time Tcp, is the earliest finish time, EF, of the last

activity found in the forward pass. In this phase, the latest finish time, LF,

and latest start time, LS, are determined for each activity. The latest finish

time LFi for a given activity, i, is the latest possible time that activity i

must be completed in order to finish the whole project on schedule. Its value

is determined by subtracting from Tcp the activity time along the longest path

leading backward from the last node. For the last activity of the schedule, LF

is set to be the total time duration of the project, Tcp. The latest finish

time, LFi , for a given activity, i, is its latest finish time minus its activity

time Tai. The calculations for the bearing overhaul example are shown in Table

11.5.

Table 11.5. Latest finish times and start

times for the example

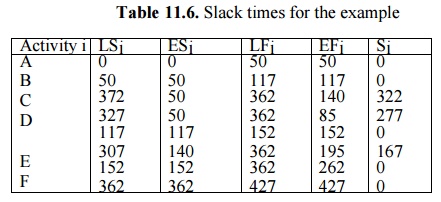

The last step in the analysis of

the network is to determine the slack time for each activity Si. It can be

determined by the difference between the latest and the earliest start time of

the activity. The calculations are shown in Table 11.6 below.

Table 11.6. Slack times for the example

Note that the activities along

the critical path (A-B-E-G-H-I) have zero slack times. Activities not lying on

the critical path have positive slacks, meaning that they could be delayed by

an amount of time equal to their slack without delaying the project completion

time.

The construction of the time chart should be made taking into

consideration the available resources, and must take full advantage of the CPM

calculation. In some circumstances it might not be possible to schedule many activities

simultaneously because of personnel and equipment limitations. The total float

for non-critical activities can be used to level the resources and minimize the

maximum resource requirement. These activities can be shifted backward and

forward between maximum allowable limits and scheduled at an appropriate time

that levels the resources and keeps a steady workforce and equipment.

In addition to resource leveling, CPM involves project

crashing. In project crashing, the duration of one or more critical activities

are shortened in an optimal fashion and a curve is prepared to show the trade

off between time and cost. This will enable management to evaluate project

duration with the resulting cost. Network programming can be used to perform

crashing in an optimal fashion. For more on project scheduling, see Taha

(1992).

Related Topics