Chapter: Mechanical : Maintenance Engineering : Maintenance Policies and Preventive Maintenance

Gantt Charts and Scheduling Theory

Scheduling

Techniques

Scheduling

is one of the areas that received considerable attention from researchers as well

as practitioners in all types of applications including operations scheduling

and project scheduling. Techniques are developed to develop optimum or near

optimal schedules with respect to different possible performance measures. This

chapter highlights some of these techniques and their application in

maintenance scheduling.

Gantt Charts and Scheduling Theory

One of

the oldest techniques available for sequencing and scheduling operations is the

Gantt chart developed by Henry L. Gantt during World War II. The Gantt chart is

a bar chart that specifies the start and finish time for each activity on a

horizontal time scale. It is very useful for showing planned work activities vs

accomplishments on the same time scale. It can also be used to show the inter-

dependencies among jobs, and the critical jobs that need special attention and

effective monitoring. There are large variations of the Gantt chart. To

demonstrate the use of the Gantt chart several examples are given below. The

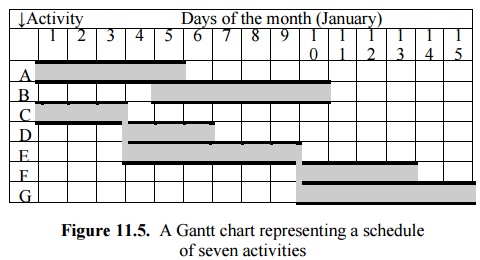

example in Figure

11.5 shows the simplest form of

the Gantt chart in which activities are scheduled at specified dates within the

month.

Figure

11.5. A Gantt chart representing a schedule of seven

activities

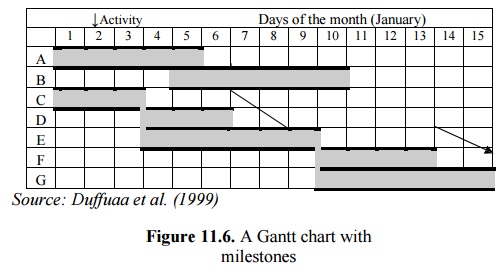

Figure 11.6. A Gantt

chart with milestones

The example

in Figure 11.5

modified to show interdependencies by

noting milestones on

each job timeline

is shown in Figure 11.6. The milestones indicate key time periods in the

duration of each

job. Solid lines

connect interrelationships among

milestones.The milestones thus indicate the interdependencies between jobs.

Obvious milestones for any job are the starting time for the job and the required

completion point. Other important milestones are significant points within a

job, such as the

point at which the start of other jobs is possible.

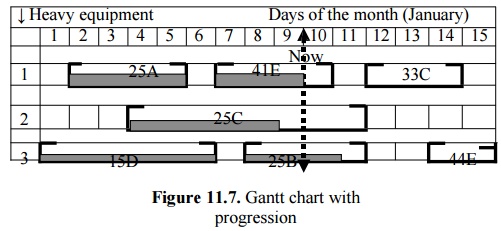

Gantt charts can also be used to show the schedule for multiple teams or equipment simultaneously. A case in which three heavy pieces of equipment are scheduled for different jobs throughout the day is shown in Figure 11.7. The actual progression indicated in the chart shows any deviation from the scheduled timing. The chart indicates that jobs 25A and 15D are completed on schedule, job 25C is behind schedule by about a full day while job 25B is ahead of schedule by about a day, and job 41E is in progress exactly on schedule. Jobs 33C and 44E scheduled but have not started yet.

Figure 11.7. Gantt

chart with progression

Color codes are sometimes used to

reflect certain conditions such as shortage of material or machine breakdowns.

Several scheduling packages, such as Primavera, are available to construct

Gantt charts for more complicated schedules involving multiple resources and

large number of activities. In general, Gantt chart does not build a schedule

but helps in presenting the schedule in a simple visible manner that might help

in monitoring, controlling and may be adjusting schedules. Scheduling (adding

new jobs to the Gantt chart) itself is done following a certain rule that is

developed with experience for the schedule to perform in the desired way. An

example of such a rule is loading the heaviest job to the least loaded

equipment as early as possible for maximizing the utilization of the equipment.

This rule is known from scheduling theory to produce a good schedule for

minimizing idle time.

Optimization techniques are

available in the literature for such cases and for other cases with multiple or

single resource. In general, scheduling theory has developed to handle short

term production scheduling in different shop structures including job shop,

flow shop, open shop and parallel machine structures See Pinedo (2002) for one

of the recent books in scheduling theory. Integer programming is commonly used

for developing optimum schedules for various scheduling requirements under

various problem structures. However, they turn out to be large scale models

that are quite complicated for real life situations. Another line of research

in scheduling theory is developing heuristic methods, some of which are quite

simple and practical, that result in good schedules with respect to certain

performance measures. Computer simulation is heavily used in testing the

performance of different competing heuristics and dispatching rules under

stochastic system behavior including machine breakdowns, and stochastically

dynamic job arrivals.

Some of the simple rules that can

be utilized in maintenance scheduling are:

• For minimizing the average job

waiting time, select jobs with high priority and short

time requirements to be scheduled first. More specifically jobs should be

ordered in increasing order of the ratio of processing time to weighted job

priority (assuming high priority jobs have high weights). This rule is known as

the weighted shortest processing time (WSPT) rule in scheduling theory.

•

For minimizing the average job waiting time having

more than one team (crew) of the same capabilities, construct the schedule by

assigning the job with the least time requirement to the fastest team.

•

Having teams of different capabilities serving for

different tasks for interrelated jobs (job shop environment), each team should

select the task belonging to the job with the most remaining time requirement.

This will

maximize the utilization of maintenance crew (or

equipment).

In spite of the developments in

scheduling theory, its use in maintenance scheduling is limited due to the

different nature of maintenance activities compared to production activities in

many aspects including:

•

Mai ntenance activities are highly

uncertain in terms of duration and resource

requirements;

•

Maintenance activities are highly related in terms

of precedence relations or relative priority;

•

Tasks can be divided into subtasks each with

different

requirements;

and

• Tas ks can be

interrupted or canceled due to changes in production

conditions or maintenance requirements.

Recent

advances in scheduling theory tended to tackle problems that are more

stochastic in nature and some research is devoted to maintenance scheduling

applications. Another recent trend in scheduling theory is the integration of

maintenance scheduling and production scheduling which are traditionally done

independently.

Related Topics