Chapter: Mechanical : Maintenance Engineering : Maintenance Policies and Preventive Maintenance

Program Evaluation Review Techniques (PERT)

Scheduling

Techniques

Scheduling

is one of the areas that received considerable attention from researchers as well

as practitioners in all types of applications including operations scheduling

and project scheduling. Techniques are developed to develop optimum or near

optimal schedules with respect to different possible performance measures. This

chapter highlights some of these techniques and their application in

maintenance scheduling.

Program

Evaluation Review Techniques (PERT)

Maintenance

activities are usually unique and commonly involve unexpected needs that make

their time duration highly uncertain. CPM uses a single estimate of the time

duration based on the judgment of a person. PERT, on the other hand,

incorporates the uncertainty by three time estimates of the same activity to

form a probabilistic description of their time requirement. Even though the

three time estimates are judgmental they provide more information about the

activity that can be used for probabilistic modeling. The three values are

represented as follows:

Oi = optimistic time, which is the time required

if execution goes extremely well;

Pi = pessimistic time, which is the time required

under the worst conditions;

and

mi = most likely time, which is the time required

under normal condition.

The

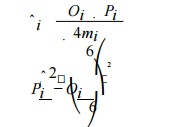

activity duration is modeled using a beta distribution with mean ( ) and

variance ( ) for each activity i estimated from the three points as follows:

Estimated means are then used to find the critical path in the

same way of the CPM method. In PERT, the total time of the critical path is a

random variable with a value that is unknown in advance. However, additional

probabilistic analysis can be conducted regarding possible project durations

based on the assumption that the total time of the project may be approximated

by a normal probability

distribution

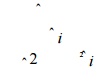

with mean and variance 2

estimated as

Using the

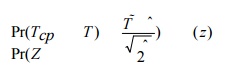

above approximation we can calculate the probability with which a project can

be completed in any time duration, T, using the normal distribution as follows:

Where Φ is the

distribution function of the standard normal distribution.

Tables exist for evaluating any

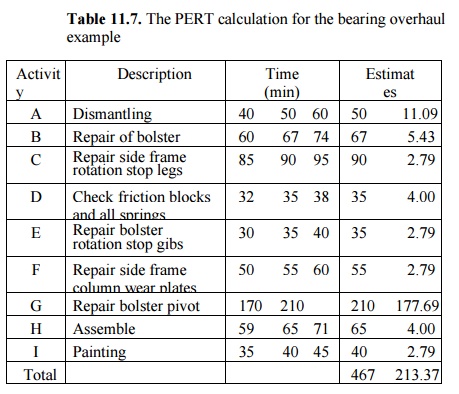

probability under the standard normal distribution. To illustrate the PERT

analysis, consider the previous example with additional time estimates shown in

Table 11.7 below.

Table

11.7. The PERT calculation for the bearing overhaul example

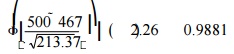

The

critical path calculations lead to the same critical path obtained in the

previous CPM calculations. The total project time is expected to be 467 min.

The estimated variance is 213.37 min. The probability that the project will

complete in

467

min can be calculated from the standard normal distribution to be

0.5,

or the project has a 50% chance

of completing in

467 min.

The probability that the project may

finish in 500 min

can be calculated as:

Related Topics