Chapter: Mechanical : Maintenance Engineering : Maintenance Policies and Preventive Maintenance

Lubrication

Lubrication

·

A Necessary Function

All material surfaces, no matter how smooth they

are, show many irregularities in the form of peaks and valleys, which are large

when considered on a molecular scale.

When these two solid surfaces are pressed over or

slide over each other, a real contact between these surfaces occurs that will

cause friction and consequently the production of heat. During the motion of

the sliding surfaces, a considerable amount of frictional heat is evolved at

the rubbing surface. This results in high local temperature even under

relatively light loads and speeds. This friction also causes a lot of wear and

tear of the surfaces of the moving parts.

Even under small load, the local pressure at the

peaks of the metals may be sufficiently great to cause appreciable deformation

in ductile metals. If two materials of different hardness slide over one

another, the peaks of the softer metal get broken more easily than the peaks of

the harder metals.

Lubrication reduces friction between the moving

surfaces or rolling pairs. The lubricant![]() also acts as a coolant carrying

heat away from the sliding surfaces, so proper lubrication of all the moving

parts is an important function in machinery or engine operation. By lubrication

we keep the moving surfaces separated by a fluid of some defined property

also acts as a coolant carrying

heat away from the sliding surfaces, so proper lubrication of all the moving

parts is an important function in machinery or engine operation. By lubrication

we keep the moving surfaces separated by a fluid of some defined property

·

Types of Lubrication

Considering the nature of motion between moving or

sliding surfaces, there are different types of mechanisms by which the

lubrication is done. They are:

· Hydrodynamic lubrication

or thick film lubrication

· Hydrostatic lubrication

· Boundary lubrication or

thin film lubrication

· Extreme pressure

lubrication

Hydrodynamic Lubrication or Thick Film Lubrication

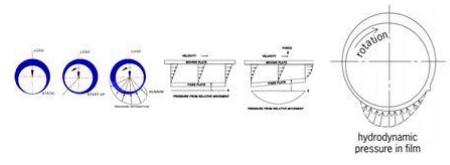

Hydrodynamic lubrication is said to exist when the

moving surfaces are separated by the pressure of a continuous unbroken film or

layer of lubrication. In this type of lubrication, the load is taken completely

by the oil film.

The basis of hydrodynamic lubrication is the

formation of an oil wedge. When the journal rotates, it creates an oil taper or

wedge between the two surfaces, and the pressure build up with the oil film

supports the load.

Hydrodynamic lubrication depends on the relative speed between

the surfaces, oil viscosity![]() , load, and clearance between the

moving or sliding surfaces.

, load, and clearance between the

moving or sliding surfaces.

In hydrodynamic lubrication the lube oil film

thickness is greater than outlet, pressure at the inlet increases quickly,

remains fairly steady having a maximum value a little to the outside of the

bearing center line, and then decreases quickly to zero at the outlet.

Application

of hydrodynamic lubrication

· Delicate

instruments.

· Light

machines like watches, clocks, guns, sewing machines.

· Scientific

instruments.

· Large

plain bearings like pedestal bearings, main bearing of diesel

engines.

Hydrocarbon oils are

considered to be satisfactory lubrication for fluid film lubrication. In

order to maintain the viscosity of the oil in all seasons of the year, ordinary

hydrocarbon lubricants are blended with selected long chain polymers.

Hydrodynamic Lubrication

lubrication system is very important in diesel

engines.Lubrication reduces friction between the moving surfaces or rolling

pairs. various types of lubrication like hydrodynamic lubrication, hydrostatic

lubrication, boundary lubrication which are used in diesel engines are

explained in this article .

Hydrostatic Lubrication

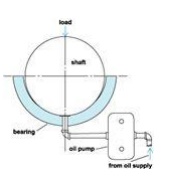

Hydrostatic lubrication is essentially a form of

hydrodynamic lubrication in which the metal surfaces are separated by a

complete film of oil, but instead of being self-generated, the separating

pressure is supplied by an external oil pump. Hydrostatic lubrication depends

on the inlet pressure of lube oil and clearance between the metal surfaces,

whereas in hydrodynamic lubrication it depends on the relative speed between

the surfaces, oil viscosity, load on the surfaces, and clearance between the

moving surfaces.

Example: the cross head pin bearing or gudgeon pin bearing in

two stroke engines employs this hydrostatic lubrication mechanism. In the cross

head bearing, the load is very high and the motion is not continuous as the

bearing oscillation is fairly short. Thus hydrodynamic lubrication cannot be

achieved. Under such conditions, hydrostatic lubrication offers the advantage.

The oil is supplied under pressure at the bottom of bearing. The lube oil pump

pressure is related to the load, bearing clearance, and thickness of the oil

film required, but is usually in the order of 35-140 kg/cm2 .

Boundary Lubrication or Thin Film Lubrication

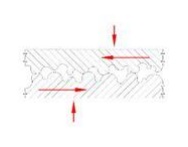

Boundary lubrication exists when the operating

condition are such that it is not possible to establish a full fluid condition,

particularly at low relative speeds between the moving or sliding surfaces.

The oil film thickness may be reduced to such a

degree that metal to metal contact occurs between the moving surfaces. The oil

film thickness is so small that oiliness becomes predominant for boundary

lubrication.

Boundary

lubrication happens when

· A shaft

starts moving from rest.

· The speed

is very low.

· The load

is very high.

· Viscosity

of the lubricant is too low.

Examples

for boundary lubrication:

· Guide and

guide shoe in two stroke engine.

· Lubrication

of the journal bearing in diesel engines (mainly during starting

and

stopping of engine).

· Piston

rings and when cylinder liner is at TDC and BDC position when the

piston

direction changes and if the relative speed is very slow.

Boundary Lubrication

Extreme Pressure

Lubrication

When the

moving or sliding surfaces are under very high pressure and speed, a high local

temperature is attained. Under such condition, liquid lubricant fails to stick

to the moving

parts and may decompose and even vaporize. To meet this extreme pressure condition, special additives are added to the minerals oils. These are called “extreme pressure lubrication.” These additives form on the metal surfaces more durable films capable of withstanding high loads and high temperature. Additives are organic compounds like chlorine (as in chlorinated esters), sulphur (as in sulphurized oils), and phosphorus.

Related Topics