Chapter: Mechanical : Maintenance Engineering : Maintenance Policies and Preventive Maintenance

Maintenance Catagories

MAINTENANCE CATAGORIES

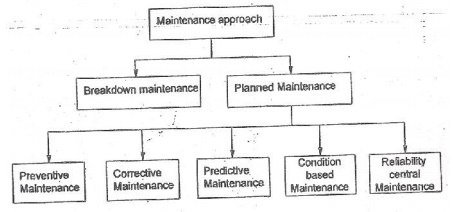

Basically there are two types of

maintenance tasks they are

Breakdown maintenance

Planned maintenance

Planned

maintenance may further be classified into

Preventive maintenance Corrective maintenance

Predictive maintenance

Condition based maintenance Reliability centered

maintenance

Corrective maintenance

The main objectives of this program are to

Eliminate breakdowns

Eliminate deviations from optimum operating

conditions

Eliminate unnecessary repairs

Optimize all critical plant

systems Preventive maintenance

It is a maintenance program which

is committed to the elimination or prevention of corrective and break down

maintenance.

Benefits of preventive maintenance

It maintains the equipment in

good condition to preventin them from bigger problems.

Prolongs the effective life of the equipments.

Detects the problem at earlier stages.

Minimize/eliminates the

rework/scrap and helps in reducing the process variability.

Significantly reduces unplanned downtime.

Predictive Maintenance

Predictive maintenance is a

management technique that uses regular evaluation of the actual operating

conditions of the plant equipment. Benefits of preventive maintenance

Reduced breakdown losses.

Reduction of quality defects. Increased net

operating profit Reduced maintenance costs

Condition based maintenance

techniques Vibration Monitoring

Determines the actual conditions

of equipments/machines by studying the noise or vibration produced during

functioning.

Thermography

Determines the condition of plant

machinery, systems etc. by studying the emissions of infra red energy i.e.

temperature

Reliability

Centered maintenance

The

rough process of RCM is as follows

1.

Target products or systems of maintenance should

be clearly identified and necessary data should be collected

2.

All possible failures and their effect on target

products or systems are systematically analyzed

Application

of RCM

When

designing, selecting and installing new systems in a plant.

When setting up preventive

maintenance for complex equipment and systems for which we are not clear on how

they work.

When teaching people the basics

of reliability it helps to explain the matters in a detailed fashion using RCM.

Related Topics