Chapter: Mechanical : Maintenance Engineering : Maintenance Policies and Preventive Maintenance

Maintenance Job Priority System

Maintenance

Job

Priority System

The

maintenance job priority system has a tremendous impact on maintenance

scheduling. Priorities are established to ensure that the most critical and

needed work is scheduled first. The development of a priority system should be

well coordinated with operations staffs who commonly assign a higher priority

to maintenance work than warranted. This tendency puts stress on the

maintenance resources and might lead to less than optimal utilization of

resources. Also, the priority system should be dynamic and must be updated

periodically to reflect changes in operation or maintenance strategies.

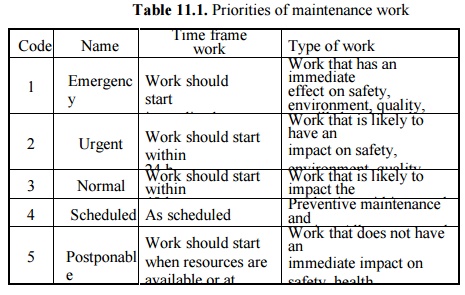

Priority systems typically include three to ten levels of priority. Most

organizations adopt four or three level priorities. Table 11.1 provides

classification of the priority level and candidate jobs to be in each class as

identified by Duffuaa et al. (1999).

Table 11.1. Priorities of maintenance work

Code Name : Time frame work : Type of work

Emergency : Work should start : Work that has an immediate

effect on safety, environment, quality,

Urgent : Work should start within : Work that is likely to

have an impact on safety, environment, quality,

Normal : Work should start within : Work that is likely to

impact the

Scheduled : As scheduled : Preventive and maintenance

Related Topics