Chapter: Mechanical : Maintenance Engineering : Maintenance Policies and Preventive Maintenance

Maintenance Scheduling

Maintenance

Scheduling

Maintenance scheduling is the process by which

jobs are matched with resources (crafts) and sequenced to be executed at

certain points in time. The maintenance schedule can be prepared in three

levels depending on the horizon of the schedule. The levels are: (1) medium

range or master schedule to cover a period of 3 months to 1 year; (2) weekly

schedule, it is the maintenance work that covers a week; and

(3)

the daily schedule covering the work to be completed each day.

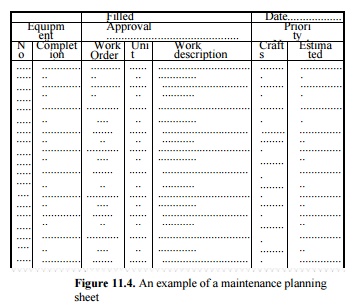

Figure 11.4. An example of a

maintenance planning sheet

The medium range schedule is

based on existing maintenance work orders including blanket work orders,

backlog, preventive maintenance, and anticipated emergency maintenance. It

should balance long term demand for maintenance work with available manpower.

Based on the long-term schedule, requirements for spare parts and material

could be identified and ordered in advance. The long- range schedule is usually

subjected to revisions and updating to reflect changes in plans and realized

maintenance work.

The

weekly maintenance schedule is generated from the medium range schedule and

takes account of current operations schedules and economic consideration. The

weekly schedule should allow for about 10–15% of

the workforce to be available for emergency work. The planner should provide

the schedule for the current week and the following one, taking into

consideration the available backlog. The work orders that are scheduled for the

current week are sequenced based on priority. Critical path analysis and

integer programming are techniques that can be used to generate a schedule. In

most small and medium sized companies, scheduling is performed based on

heuristic rules and experience.

The daily schedule is generated from the weekly schedule and is usually prepared the day before. This schedule is frequently interrupted to perform emergency maintenance. The established priorities are used to schedule the jobs. In some organizations the schedule is handed to the area foreman and he is given the freedom to assign the work to his crafts with the condition that he has to accomplish jobs according to the established priority.

Related Topics