Types, Laboratory Facilities, Technique Involved - Plant Tissue Culture (PTC) | 12th Botany : Chapter 5 : Plant Tissue Culture

Chapter: 12th Botany : Chapter 5 : Plant Tissue Culture

Plant Tissue Culture (PTC)

Plant Tissue Culture (PTC)

Plant tissue culture is used to describe the in vitro and

aseptic growth of any plant part on a tissue culture medium. This technology

is based on three fundamental principles:

•

The plant part or explant must be selected and isolated from the rest of plant

body.

•

The explant must be maintained in controlled physically (environmental) and

chemically defined (nutrient medium) conditions.

Explant: The tissue taken from a selected plant transferred to a

culture medium often to establish a new plant.

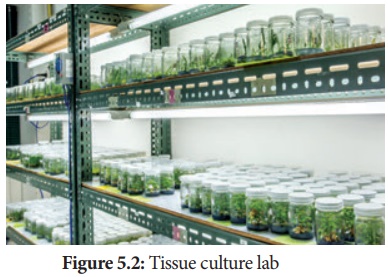

1. Laboratory Facilities for PTC

For PTC, the laboratory must have the following facilities:

·

Washing facility for glassware and ovens for drying glassware.

·

Medium preparation room with autoclave, electronic balance and pH

meter.

·

Transfer area sterile room with laminar air-flow bench and a

positive pressure ventilation unit called High Efficiency Particulate Air

(HEPA) filter to maintain aseptic condition.

·

Culture facility: Growing the explant inoculated into culture

tubes at 22-28° C with illumination of light 2400 lux, with a photoperiod of

8-16 hours and a relative humidity of about 60%.

2. Technique Involved in PTC

1. Sterilization:

Sterilization is the technique employed to get rid of microbes

such as bacteria and fungi in the culture medium, vessels and explants.

i.

Maintenance of Aseptic Environment: During in vitro tissue

culture maintenance of aseptic environmental condition should be followed,

i.e., sterilization of glassware, forceps, scalpels, and all accessories in wet

steam sterilization by autoclaving at 15 psi (121°C) for 15 to 30 minutes or

dipping in 70% ethanol followed by flaming and cooling.

ii.

Sterilization of culture room: Floor and walls are washed first with

detergent and then with 2% sodium hypochlorite or 95% ethanol. The cabinet of

laminar airflow is sterilized by clearing the work surface with 95% ethanol and

then exposure of UV radiation for 15 minutes.

iii.

Sterilization of Nutrient Media: Culture media are

dispensed in glass containers, plugged with non-absorbent cotton or sealed with

plastic closures and then sterilized using autoclave at 15 psi (121°C) for 15

to 30 minutes. The plant extracts, vitamins, amino acids and hormones are

sterilized by passing through Millipore filter with 0.2 mm pore diameter and

then added to sterilized culture medium inside Laminar Airflow Chamber under

sterile condition.

iv.

Sterilization of Explants: The plant materials to be used for tissue

culture should be surface sterilized by first exposing the material in running

tap water and then treating it in surface sterilization agents like 0.1%

mercuric chloride, 70% ethanol under aseptic condition inside the Laminar Air

Flow Chamber.

2. Media Preparation

The success of tissue culture lies in the composition of the

growth medium, plant growth regulators and culture conditions such as

temperature, pH, light and humidity. No single medium is capable of maintaining

optimum growth of all plant tissues. Suitable nutrient medium as per the

principle of tissue culture is prepared and used.

MS nutrient medium (Murashige and Skoog 1962) is commonly used. It

has carbon sources, with suitable vitamins and hormones. The media formulations

available for plant tissue culture other than MS are B5 medium (Gamborg.et.al

1968), White medium (white 1943), Nitsch’s medium (Nitsch & Nitsch 1969). A

medium may be solid or semisolid or liquid. For solidification, a gelling agent

such as agar is added.

Agar: A complex mucilaginous polysaccharide obtained from marine

algae (sea weeds) used as solidifying agent in media preparation.

Composition of MS (Murashige and

Skoog) Medium

Macronutrients:

Ammonium

nitrate (NH4NO3) 1650.0 mg/l

Potassium

nitrate (KNO3) 1900.0 mg/l

Calcium

chloride (CaCl2 2H2O) 440.0 mg/l

Magnesium

sulphate (MgSO4 6H2O) 370.0 mg/l

Potassium

dihydrogen phosphate (KH2PO4) 170.0 mg/l

Micronutrients:

Manganese

sulphate (MnSO4 4H2O) 22.3 mg/l

Zinc

sulphate (ZnSO4 4H2O) 8.6 mg/l

Boric

acid (H3BO3) 6.2 mg/l

Potassium

iodide (KI) 0.83 mg/l

Minor nutrient:

Sodium

molybdate (Na2 MO4 2H2O) 0.250 mg/l

Cupric

sulphate (CuSO4 5H2O) 0.025 mg/l

Cobaltous

chloride (CoCl2 6H2O) 0.025 mg/l

Iron stock

Na

EDTA 37.25 mg/l

Ferrous

Sulphate (FeSO4 7H2O) 27.85 mg/l

Vitamins

Glycine

2.0 mg/l

Nicotinic

acid 0.5 mg/l

Pyridoxin

HCl 0.5 mg/l

Thaiamine

HCl 0.1 mg/l

Growth Hormones

IAA

1.30 mg/l

Kinetin

0.4–10.0 mg/l

Myo-inositol

100.0 mg/l

Sucrose

30.0 g/l

Solidifying Agent

Agar 8.0 g/l

3. Culture condition

pH

The pH of medium is normally adjusted between 5.6 to 6.0 for the

best result.

Temperature

The cultures should be incubated normally at constant temperature

of 25°C ± 2°C for optimal growth.

Humidity and Light Intensity

The cultures require 50-60% relative humidity and 16 hours of

photoperiod by the illumination of cool white fluorescent tubes of

approximately 1000 lux.

Aeration

Aeration to the culture can be provided by shaking the flasks or

tubes of liquid culture on automatic shaker or aeration of the medium by

passing with filter-sterilized air.

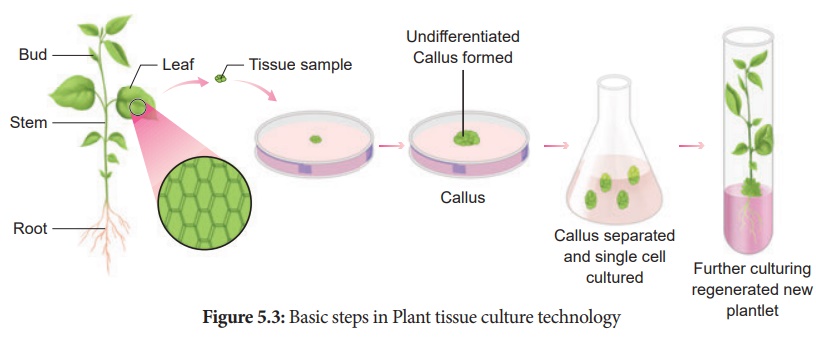

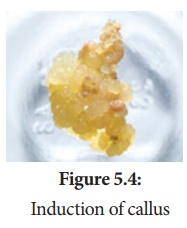

4. Induction of Callus

Explant of 1-2 cm sterile segment selected from leaf, stem, tuber or root is inoculated (transferring the explants to sterile glass tube containing nutrient medium) in the MS nutrient medium supplemented with auxins and incubated at 25°C ± 2°C in an alternate light and dark period of 12 hours to induce cell division and soon the upper surface of explant develops into callus. Callus is a mass of unorganized growth of plant cells or tissues in in vitro culture medium.

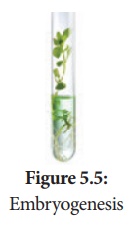

5. Embryogenesis

The callus cells undergoes differentiation and produces somatic

embryos, known as Embryoids. The embryoids are sub-cultured to

produce plantlets.

6. Hardening

The plantlets developed in vitro require a hardening period and so are transferred to greenhouse or hardening chamber and then to normal environmental conditions.

Hardening is the gradual exposure of in vitro developed

plantlets in humid chambers in diffused light for acclimatization so as to

enable them to grow under normal field conditions.

3. Types of Plant tissue cultures

Based on the explants some other plant tissue culture types are

1. Organ culture

2. Meristem culture

3. Protoplast culture

4. Cell culture.

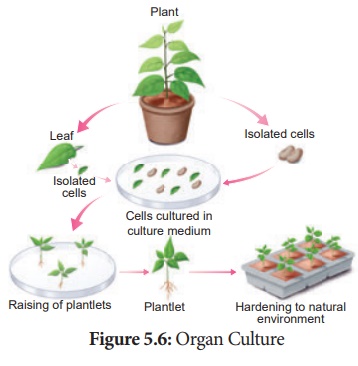

1. Organ culture

The culture of embryos, anthers, ovaries, roots, shoots or other

organs of plants on culture media.

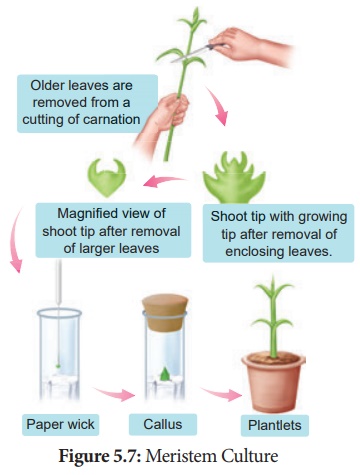

2. Meristem Culture:

The culture of any plant meristematic tissue on culture media.

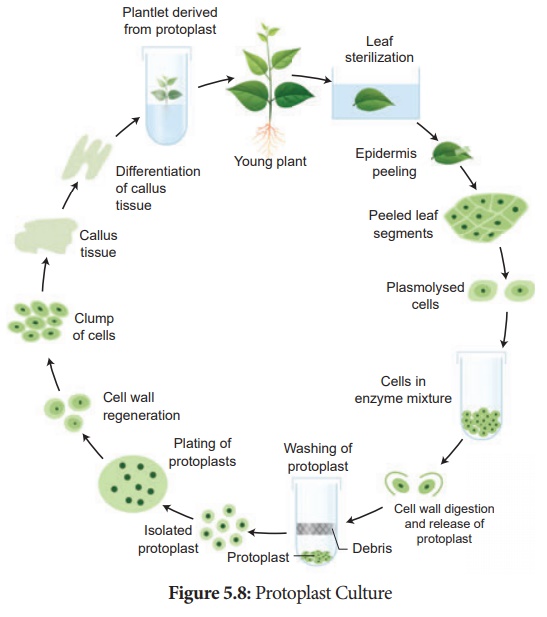

3. Protoplast Culture:

Protoplasts are cells without a cell wall, but bounded by a cell

membrane or plasma membrane. Using protoplasts, it is possible to regenerate

whole plants from single cells and also develop somatic hybrids. The steps

involved in protoplast culture.

i. Isolation of protoplast: Small bits of plant tissue like leaf

tissue are used for isolation of protoplast. The leaf tissue is immersed in

0.5% Macrozyme and 2% Onozuka cellulase enzymes dissolved in 13% sorbitol or

mannitol at pH 5.4. It is then incubated over-night at 25°C. After a gentle

teasing of cells, protoplasts are obtained, and these are then transferred to

20% sucrose solution to retain their viability. They are then centrifuged to

get pure protoplasts as different from debris of cell walls.

ii. Fusion of protoplast: It is done through the

use of a suitable fusogen. This is normally PEG (Polyethylene Glycol). The

isolated protoplast are incubated in 25 to 30% concentration of PEG with Ca++

ions and the protoplast shows agglutination (the formation of clumps of cells)

and fusion.

iii. Culture of protoplast: MS liquid medium is used

with some modification in droplet, plating or micro-drop array techniques.

Protoplast viability is tested with fluorescein diacetate before the culture.

The cultures are incubated in continuous light 1000-2000 lux at 25°C. The cell

wall formation occurs within 24-48 hours and the first division of new cells

occurs between 2-7 days of culture.

iv. Selection of somatic hybrid cells: The fusion

product of protoplasts without nucleus of different cells is called a cybrid.

Following this nuclear fusion happen. This process is called somatic

hybridization.

4. Cell Suspension Culture

The growing of cells including the culture of single cells or

small aggregates of cells in vitro in liquid medium is known as cell suspension

culture. The cell suspension is prepared by transferring a portion of callus to

the liquid medium and agitated using rotary shaker instrument. The cells are

separated from the callus tissue and used for cell suspension culture.

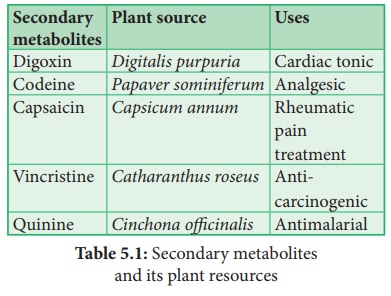

Production of Secondary Metabolites

Cell suspension culture can be useful for the production of

secondary metabolites like alkaloids, flavonoids, terpenoids, phenolic

compounds and recombinant proteins. Secondary metabolites are chemical

compounds that are not required by the plant for normal growth and development

but are produced in the plant as ‘byproducts’ of cell metabolism. For Example:

Biosynthesis and isolation of indole alkaloids from Catharanthus roseus plant

cell culture.

The process of

production of secondary metabolites can be scaled up and automated using

bio-reactors for commercial production. Many strategies such as

biotransformation, elicitation and immobilization have been used to make cell

suspension cultures more efficient in the production of secondary metabolites.

Few examples of industrially important plant secondary metabolites are listed

below in the table:

Related Topics