Chapter: Civil : Construction Planning And Scheduling

Estimating Activity Durations

Construction

Planning:

Estimating

Activity Durations

In most scheduling procedures, each work activity

has associated time duration. These durations are used extensively in preparing

a schedule. For example, suppose that the durations shown in Table 9-3 were

estimated for the project diagrammed in Figure 1-0. The entire set of

activities would then require at least 3 days, since the activities follow one

another directly and require a total of 1.0 + 0.5 + 0.5 + 1.0 = 3 days. If

another activity proceeded in parallel with this sequence, the 3 day minimum

duration of these four activities is unaffected. More than 3 days would be

required for the sequence if there was a delay or a lag between the completion

of one activity and the start of another.

All formal scheduling procedures rely upon

estimates of the durations of the various project activities as well as the

definitions of the predecessor relationships among tasks. The variability of an

activity's duration may also be considered. Formally, the probability

distribution of an activity's duration as well as the expected or most likely

duration may be used in scheduling. A probability distribution indicates the

chance that particular activity duration will occur. In advance of actually

doing a particular task, we cannot be certain exactly how long the task will

require.

A straightforward approach to the estimation of

activity durations is to keep historical records of particular activities and

rely on the average durations from this experience in making new duration

estimates. Since the scopes of activities are unlikely to be identical between

different projects, unit productivity rates are typically employed for this

purpose. For example, the duration of an activity Dij

such as

concrete formwork assembly might be estimated as:

Dv = Ag /

FgNg

Where Aij is the required formwork area

to assemble (in square yards), Pij is the average productivity of a

standard crew in this task (measured in square yards per hour), and Nij

is the number of crews assigned to the task. In some organizations, unit

production time, Tij, is defined as the time

required to complete a unit of work by a standard crew

(measured in hours per square yards) is used as a productivity measure such

that Tij is a reciprocal of Pij.

A formula such as Eq. (1.1) can be used for nearly

all construction activities. Typically, the required quantity of work, Aij

is determined from detailed examination of the final facility design. This

quantity-take-off to obtain the required amounts of materials,

volumes, and areas is a very common process in bid preparation by contractors.

In some countries, specialized quantity surveyors provide the information on

required quantities for all potential contractors and the owner. The

number of crews working, Nij, is decided by the planner. In

many cases, the number or amount of resources applied to

particular

activities may be modified in light of the resulting project plan and schedule.

Finally, some estimate of the expected work productivity, Pij must

be provided to apply Equation (1.1). As with cost factors,

commercial services can provide average productivity figures for many standard

activities of this sort. Historical records in a firm can also provide data for

estimation of productivities.

The calculation of a duration as in Equation (9.1)

is only an approximation to the actual activity duration for a number of

reasons. First, it is usually the case that peculiarities of the project make

the accomplishment of a particular activity more or less difficult. For

example, access to the forms in a particular location may be difficult; as a

result, the productivity of assembling forms may be lower than the average

value for a particular project. Often, adjustments based on engineering

judgment are made to the calculated durations from Equation (9.1) for this

reason.

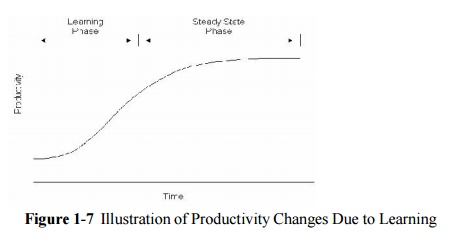

In addition, productivity rates may vary in both

systematic and random fashions from the average. An example of systematic

variation is the effect of learning on productivity. As a crew becomes familiar

with an activity and the work habits of the crew, their productivity will

typically improve. Figure 9-7 illustrates the type of productivity increase

that might occur with experience; this curve is called a learning curve. The

result is that productivity Pij is a function of the duration of an

activity or project. A

common

construction example is that the assembly of floors in a building might go

faster at higher levels due to improved productivity even though the

transportation time up to the active construction area is longer. Again,

historical records or subjective adjustments might be made to represent

learning curve variations in average productivity.

Random factors will also influence productivity

rates and make estimation of activity durations uncertain. For example, a

scheduler will typically not know at the time of making the initial schedule

how skillful the crew and manager will be that are assigned to a particular

project. The productivity of a skilled designer may be many times that of an

unskilled engineer. In the absence of specific knowledge, the estimator can

only use average values of productivity.

Weather effects are often very important and thus

deserve particular attention in estimating durations. Weather has both

systematic and random influences on activity durations. Whether or not a

rainstorm will come on a particular day is certainly a random effect that will

influence the productivity of many activities. However, the likelihood of a

rainstorm is likely to vary systematically from one month or one site to the next.

Adjustment factors for inclement weather as well as meteorological records can

be used to incorporate the effects of weather on durations. As a simple

example, an activity might require ten days in perfect weather, but the

activity could not proceed in the rain. Furthermore, suppose that rain is

expected ten percent of the days in a particular month. In this case, the

expected activity duration is eleven days including one expected rain day.

Finally, the use of average productivity factors themselves cause

problems in the calculation presented in Equation (1.1). The expected value of

the multiplicative reciprocal of a variable is not exactly equal to the

reciprocal of the variable's expected value. For example, if productivity on an

activity is either six in good weather (ie., P=6) or two in bad weather (ie.,

P=2) and good or bad weather is equally likely, then the expected productivity

is P = (6)(0.5) + (2) (0.5) = 4, and the reciprocal of expected productivity is

1/4. However, the expected reciprocal of productivity is E[1/P] = (0.5)/6 +

(0.5)/2 = 1/3. The reciprocal of expected productivity is 25% less than the

expected value of the reciprocal in this case! By representing only two

possible productivity values, this example represents an extreme case, but it

is always true that the use of average productivity factors in Equation (1.1)

will result in optimistic estimates of activity durations. The use of actual

averages for the reciprocals of productivity or small adjustment factors may be

used to correct for this non-linearity problem.

The simple duration calculation shown in Equation

(1.1) also assumes an inverse linear relationship between the number of crews

assigned to an activity and the total duration of work. While this is a

reasonable assumption in situations for which crews can work independently and

require no special coordination, it need not always be true. For example,

design tasks may be divided among numerous architects and engineers, but delays

to insure proper coordination and communication increase as the number of

workers increase. As another example, insuring a smooth flow of material to all

crews on a site may be increasingly difficult as the number of crews increase.

In these latter cases, the relationship between activity duration and the

number of crews is unlikely to be inversely proportional as shown in Equation

(1.1). As a result, adjustments to the estimated productivity from Equation

(1.1) must be made. Alternatively, more complicated functional relationships

might be estimated between duration and resources used in the same way that

nonlinear preliminary or conceptual cost estimate models are prepared.

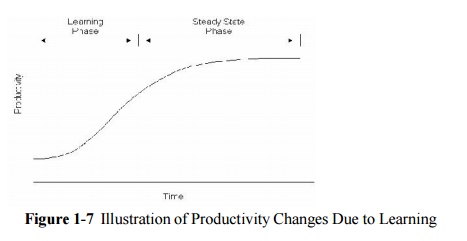

One

mechanism to formalize the estimation of activity durations is to employ a

hierarchical estimation framework. This approach decomposes the estimation

problem into component parts in which the higher levels in the hierarchy

represent attributes which depend upon the details of lower level adjustments

and calculations. For example, Figure 1-8 represents various levels in the estimation

of the duration of masonry construction. At the lowest level, the maximum

productivity for the activity is estimated based upon general work conditions.

Table 1-4 illustrates some possible maximum productivity values that might be

employed in this estimation. At the next higher level, adjustments to these

maximum productivities are made to account for special site conditions and crew

compositions; table 1-5 illustrates some possible adjustment rules. At the

highest level, adjustments for overall effects such as weather are introduced.

Also shown in Figure 1-8 are nodes to estimate down or unproductive time

associated with the masonry construction activity. The formalization of the

estimation process illustrated in Figure 1-8 permits the development of

computer aids for the estimation process or can serve as a conceptual framework

for a human estimator.

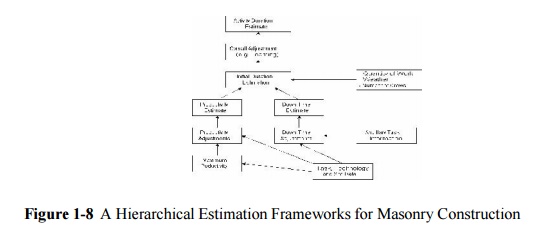

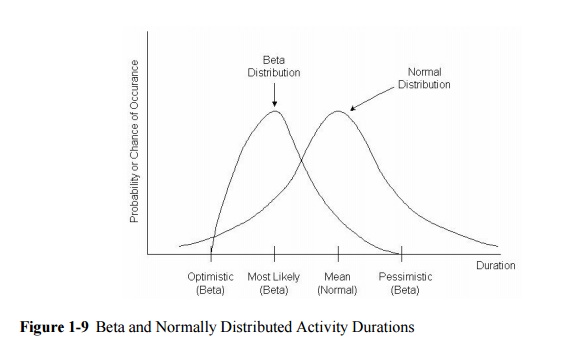

In addition to the problem of estimating the

expected duration of an activity, some scheduling procedures explicitly

consider the uncertainty in activity duration estimates by using the

probabilistic distribution of activity durations. That is, the duration of a

particular activity is assu med to be a random variable that is distributed in

a particular fashion. For example, an activity duration might be assumed to be

distributed as a normal or a beta distributed random variable as illustrated in

Figure 9-9. This figure shows the probability or chance of experiencing a

particular activity duration based on a probabilistic distribution. The beta

distribution is often used to characterize activity durations, since it can

have an absolute minimum and an absolute maximum of possible duration times.

The normal distribution is a good approximation to the beta distribution in the

center of the distribution and is easy to work with, so it is often used as an

approximation.

If a standard random variable is used to

characterize the distribution of activity durations, then only a few parameters

are required to calculate the probability of any particular duration. Still,

the estimation problem is increased considerably since more than one parameter

is required to characterize most of the probabilistic distribution used to

represent activity durations. For the beta distribution, three or four

parameters are required depending on its generality, whereas the normal

distribution requires two parameters.

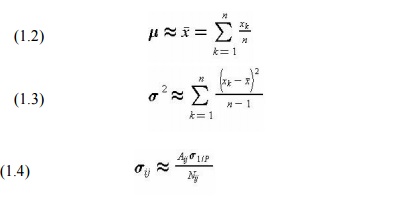

As an example, the normal

distribution is characterized by two parameters, ![]() and

and ![]() representing the average duration and the

standard deviation of the duration, respectively. Alternatively, the variance

of the distribution

representing the average duration and the

standard deviation of the duration, respectively. Alternatively, the variance

of the distribution ![]() could be used to describe or characterize the

could be used to describe or characterize the

variability

of duration times; the variance is the value of the standard deviation

multiplied by itself. From historical data, these two parameters can be estimated

as:

where we assume that n different observations xk

of the random variable x are available. This estimation process might be

applied to activity durations directly (so that xk would be a record

of an activity duration Dij on a past project) or to the estimation

of the distribution of productivities (so that xk would be a record

of the productivity in an activity Pi) on a past project) which, in

turn, is used to

estimate

durations using Equation (1.4). If more accuracy is desired, the estimation equations

for mean and standard deviation, Equations (1.2) and (1.3) would be used to

estimate the mean and standard deviation of the reciprocal of productivity to

avoid non-linear effects. Using estimates of productivities, the standard

deviation of activity duration would be calculated as:

where Ro (p) is the estimated standard deviation of the

reciprocal of productivity that is calculated from Equation (1.3) by

substituting 1/P for x.

Related Topics