Chapter: 11th 12th std standard Political Science History goverment rule laws life Higher secondary school College Notes

Wool - Animal Fiber : History, Processing, Classification for wool and by Fleece, Manufacturing, Properties

Animal Fibers:

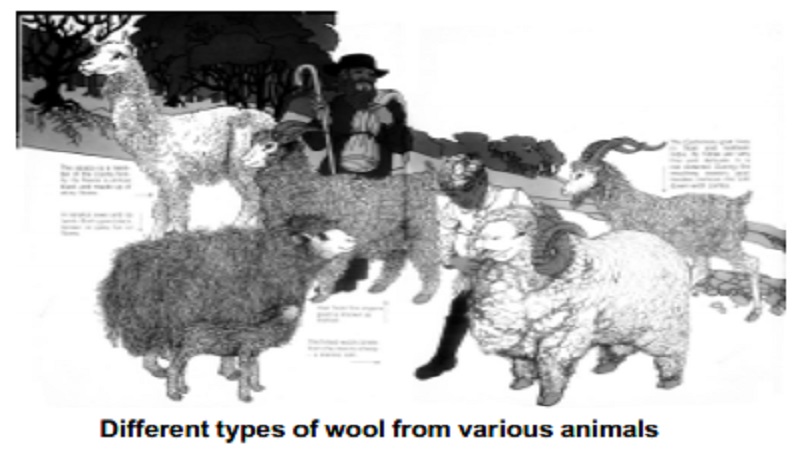

Natural protein fibers are obtained from animal sources like hair and other secretion, fibers include covering from such animals as sheep, mohair goat, cashmere goat and camel. Secretions are obtained from the larva, or worm stage, of the silkworm, which spins the cocoon from which silk fibers are obtained and from the spider which spins fine fibers in making its web. There are some properties of hair fibers and secretions which are quite similar and on the other hand there are properties which are totally different.

Wool:

The word wool was wull in old English. Wool is the fiber from the fleece of domesticated sheep.

Principal Origin : Natural

Chemical type : Proteinaceous

Generic name : Animal hair

Common name : Wool

a. History:

When wild sheep were killed by primitive people for food they used the pelts as body coverings. It is believed that ancient shepherd in the first century A.D. discovered that Merino sheep could be bred to improve the fleece. Soft wool is developed by breeding different species of animals. It provides warmth and physical comfort. These quality combined with soft resiliency make wool desirable for apparel as well as for such household uses as rugs and blankets. The quality of wool fiber is determined by the breeding, climate, food, general care and health of sheep. Cold weather produces a hardier and heavier fiber. Excessive moisture dries out natural grease. Insufficient or poor food retards growth.

b. Processing:

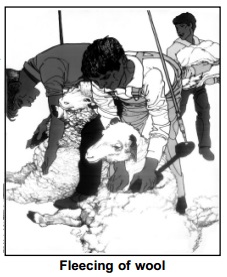

To produce good quality of wool, sheep are prevented against disease by chemicals and are fed nutritional diets. Wool can be sheared from the living animal or pulled from the hide after the animal has been slaughtered for its meat or it is dead due to some disease or something. The sheared wool is called fleece or clip wool. Fibers taken from the slaughtered animal hide are called pulled wool. It is not as good as clipped wool. The shearing of clipped wool can be done manually or chemically. In chemical shearing the animal is fed a special chemical, which causes the wool to become loose from the skin, or fall away and it can then be brushed together and removed without mechanical shearing.

Pulled wool can be removed by treating with a depilatory that loosens the fibers and permits them to be pulled away from skin without damaging the hide or it can be loosened by the action of bacteria on the root end of the fiber. Pulled wool when used is usually mixed with fleece wool before processing into yarns and fabrics.

c. Classification for wool:

There are about 40 breeds of sheep and more than 200 which are crossbred. Wool producing sheep may be classified into four groupings according to the Wool Quality.

1. Merino wool:

Merino sheep produces best wool. It is found in Spain. The staple is relatively short.

Ranging from 1 to 5 inches but the fiber is strong, fine and elastic and has good working properties. It has greatest amount of crimp and has maximum number of scales. Used for best wool clothing.

2. Class-two wools:

This variety is not less than a very good quality wool. Its fiber is 2 to 8 inches in length, has a large number of scales per inch and has good crimp. The fibers are strong, fine and elastic and have good working properties. Found in England, Scotland and Ireland.

3. Class-three wools:

The fibers are from 4 to 18 inches long and are coarsened have few scales and less crimp than merino and class-two wool. Smoother and more lustrous. Good enough for clothing. Originated in U.K.

4. Class-four wools:

This class refers to half-breeds. Fiber length ranges from 1 to 16 inches, coarse, hairlike have relatively few scales and little crimp and are smooth and lustrous. Mainly used for carpets, rugs and inexpensive low-grade clothing.

d. Classification by Fleece:

Wool shorn from young lambs differs in quality from that of older sheep. Also, fleece differ according to whether they come from live or dead sheep, which necessitates standards for the classification of fleece.

1. Lamb's wool:

The first Fleece sheared from a lamb about six to eight months old is known as lamb's wool and or fleece or first clip wool. This wool is of very-very fine quality. The fibers are extremely soft.

2. Hogget Wool:

Wool from 12 to 14 month old sheep for the first time. The fiber is fine, soft, resilient and mature. Good strength and is used for warps.

3. Pulled Wool:

Wool from slaughtered animal and is of inferior quality as quality of wool is not as good and roots of fibers are generally damaged.

4. Dead Wool:

Wool from dead animal which is inferior in grade.

5. Taglocks:

The tom, ragged or discolored parts of a fleece are known as taglocks.

6. Recycled wool:

Old woolen stuff is broken to make woolen fibers and shred them to yarns again.

e. Manufacturing Process:

Long and short fleece are separated. Superior wool comes from the sides and shoulders, where it grows longer, finer and softer, and is treated as one fleece; wool from the head, chest, belly and shanks is treated as second fleece. The wool is packed in bags or bales. The raw wool is called grease wool because it has natural oils of sheep. It is washed and the grease is used in the pharmaceutical industries. Wool is then sorted which is the process of breaking up an individual fleece into its different qualities. Recycled wool fibers are obtained by separately reducing the unused and used material to a fibrous mass by a picking and shredding process called garneting. This is then treated with acids and the process is called carbonizing and the process is called scouring. The wool is then dried leaving 12 to 16% of the moisture. As the wool is unmanageable after scouring, the fiber is usually treated with various oils, including animal, vegetable, and mineral or a blend of these to keep it from becoming brittle and to lubricate it for spinning. The wool is then dyed if required and blended.

f. Properties of wool:

Shape : Length varies from 1�' to 15" has scales on its surface.

Luster : Medium

Elongation : Good

Resiliency : Excellent

Density : 1.30 - 1.32 g/ccm

Moisture absorption : Good

Dimensional stability : Subject to felting and relaxation shrinkage.

Resistance to acids : Good

Resistance to alkalies : Low; many alkalies destroy the fiber.

Sunlight : Prolonged exposure deteriorates fiber

Insects : Damaged by moths and carpet Beetles.

To flame : Burns slowly when in direct flame, is considered to be self extinguishing.

Related Topics