Chapter: Aquaculture Engineering : Water Transport

Valves - Pipe and pipe parts

Valves

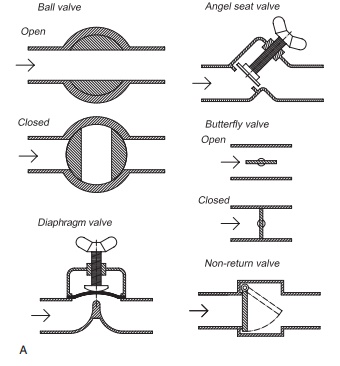

Valves are used to regulate the water flow rate and the

flow direction. Many types of valve are used in aquaculture (Fig. 2.3). Which

type to use must be chosen on the basis of the flow in the system and the

specific needs of the farm. Several materials are used in valves, such as PVC,

ABS, PP and PVDF, and the material chosen depends on where the valves will be

used. Large valves may also be fabricated in stainless or acid proof steel.

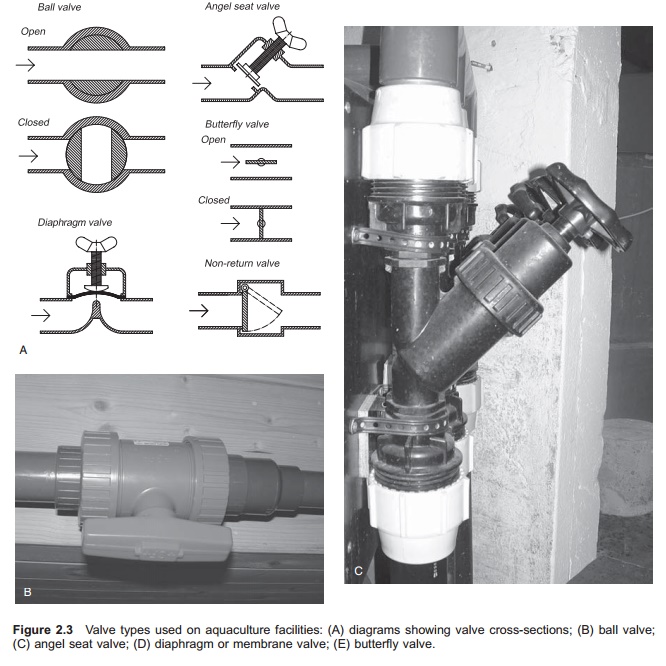

Ball valves are low cost solutions used in aqua-culture.

The disadvantage is that they are not very precise when regulating the water

flow. They are best used in an on/off manner, or for approximate regulation of

the water flow. The design is simple and consists of a ball with an opened

centre. When turning it will gradually open or close.

Valves constructed with a membrane pulled down by a piston

for regulation of water flow are called diaphragm or membrane valves. These

valves can regulate water flow very accurately. They cost considerably more

than a ball valve, and the head loss through the valve is significantly higher.

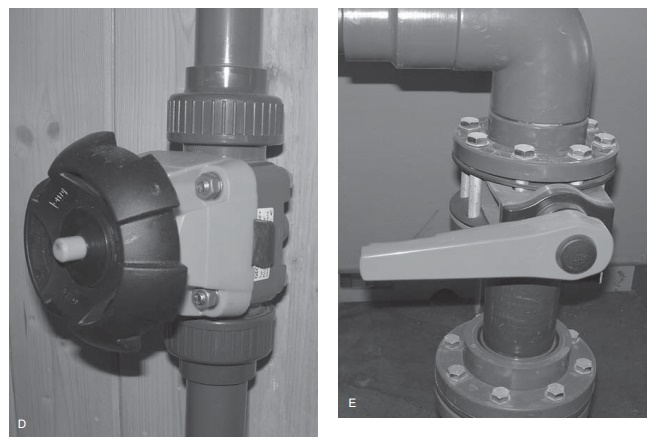

Angle seat valves have a piston standing in an angled

‘seat’. When the screw handle is turned the piston moves up or down. The

opening is gradually reduced by pressing the piston down. This type of valve is

also capable of accurate flow regulation, but is quite expensive and has also a

higher head loss than a ball valve. For accurate flow regulation, for instance

on single tanks, diaphragm valves or angle seat valves are recommended. When

selecting these types of valves it is, however, important to be aware that the

head loss can be over five times as high as with a ball valve.

Butterfly valves are usually located in large pipes (main pipeline or part pipelines) and regulate the water flow by opening or closing a throttle. Which is located inside a pipe part; by turning the throttle the passage for the water inside the pipe is changed. A slide valve or gate valve can be used for the same cases. This consists of a gate or slide that stands ver-tically in the water flow; the water flow is regulated by lifting or lowering the plate by a spindle. This valve type is also used in large diameter pipelines, but both butterfly valves and sluice valves are quite expensive, especially in large sizes. It is, however, better to use too many valves than too few. To have the facility to turn off the water flow at several places in the farm, for instance for maintenance, will always be an advantage. These types of valves are, however, not recommended for precise regulation of water flow.

The check valve or ‘non-return’ valve is used to avoid the

backflow of water; this means that the water can only flow in one direction in

the pipe system. In many cases it is used in a pump outletto avoid backflow of

water when the pump stops. Normally the valve is comprises a plate or ball that

closes when the water flow tends to go in the opposite direction.

Triple way valves may regulate the flow in two directions to create a bypass. There are also many other types of valves, for instance electrically or pneumatically operated valves which make it possible to regulate water flow functions automati-cally. In new and advanced fish farms such equip-ment is of increasing interest, especially when saving of water is necessary.

It is important to remember, however, that all valves

create a head loss, the size of which depends on the type of valve being used;

for example, diaphragm valves have a high head loss. This must considered when

planning the farm and deciding which valve types to use. It is necessary to

have enough pressure to ensure that the correct flow rate is maintained through

the valves; if the head loss is too high the water flow into or inside the farm

will be decreased.

Related Topics