Chapter: Aquaculture Engineering : Water Transport

Mooring of pipes

Mooring of pipes

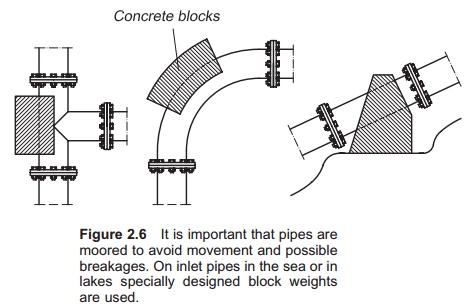

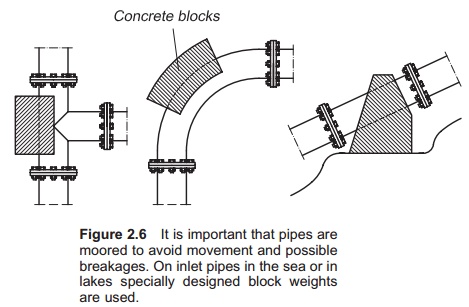

Pipes may carry large amounts of water at high velocities. This generates large forces that may cause movements of the pipe. In the worst case this can damage the pipeline. For this reason a correct mooring system for the pipeline is of great impor-tance (Fig. 2.6).

When there is a reduction in the pipe size, or when using

T-pipes or elbows, there is an increase in the forces dependent on the

velocity, and there will normally be a need for mooring to avoid move-ments and

breakage of the pipes. Putting the pipes in a ditch will stabilize them and the

ditch will func-tion as a mooring for the pipe. In exposed places, however, it

may also be necessary to have addi-tional moorings; concrete blocks may, for

instance, be used on elbows. This also shows the importance of having smooth

pipe linings. In indoor facilities clamps are used to attach the pipes to the

ceiling, walls or floor, and in this way moor and stabilize the pipes.

Inlet or outlet pipes placed underwater or sub-surface in

the sea or lakes require moorings. Spe-cially designed concrete block weights

are normally used to moor pipes to the ground (Fig. 2.6) to prevent them

floating to the surface as a result of their buoyancy, especially when they are

empty or only partly filled with water. The distance between the weights

depends on the pipe type, diameter, weight size and expected water flow. When

placing outlet pipes sub-surface, it is important to consider the weight of the

pipe both when filled with water and filled with air, the buoyancy being much

greater in the latter case which will also increase the requirements for

weights. Usually pipe suppliers have their own mooring tables with recommended

block weights and distance between them.

Related Topics