Chapter: Aquaculture Engineering : Water Transport

Centrifugal and propeller pumps

Centrifugal and propeller pumps

Centrifugal pumps

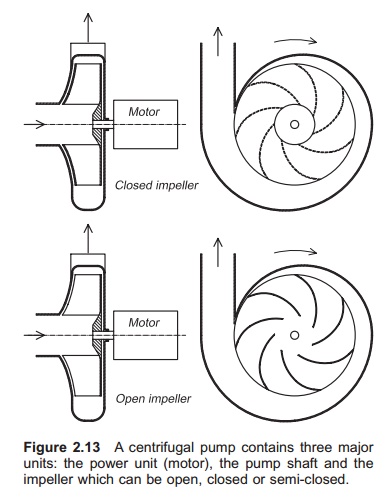

Centrifugal pumps account for the majority of those used by aquaculture enterprises. A centrifu-gal pump contains three major units: the power unit, the pump shaft and the impeller (Fig. 2.13). The power unit, an electric motor, causes the pump shaft to rotate and with it the attached impeller. Around the rotating shaft where the impeller and motor are fixed there are seals that prevents leakage via the shaft into the motor.

If the inlet and the pump cavity are filled with water (primed), the rotation of the impeller causes movement of water molecules which will be accel-erated outwards towards the periphery of the impeller. This will reduce the pressure in the centre of the impeller and new water is drawn into the eye of the impeller via the pump inlet. Vanes on the impeller may direct the flow of water and help to transfer the energy from the impeller to the water.

The rotation of the impeller imparts high veloc-ity to water molecules at the periphery. When this water leaves the impeller, the velocity is rapidly reduced and the dynamic head is converted to static head. How the pressure changes from the inlet to the outlet on a centrifugal pump depends on the characteristics of the pump. The outlet pressure is a function of the inlet pressure and pump character-istics, mainly the design of the impeller.

The impeller may be open, semi-closed or enclosed; all have different characteristics (Fig. 2.13). The choice depends on the amount of partic-ulate matter in the water. If there are many parti-cles (sludge like), an open or semi-closed impeller is normally used; if there are few particles or high pressure is required, an enclosed impeller is used. The enclosed impeller has the highest efficiency, but tolerates the lowest amount of suspended solids in the water. In aquaculture facilities all types of impeller are used.

Propeller pump

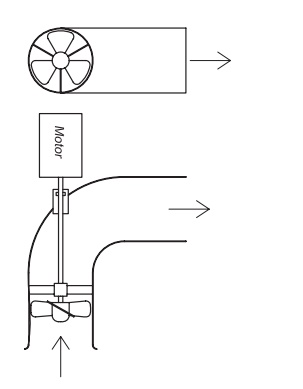

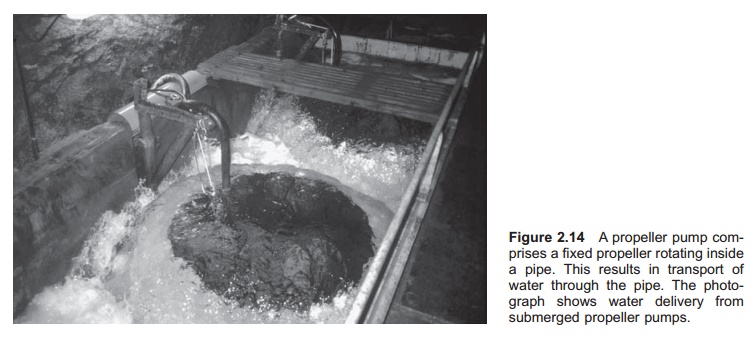

Propeller pumps are of simple construction with a propeller rotating inside a pipe (Fig. 2.14). The prin-ciple is the same as a propeller on a boat, but instead of moving the boat, the propeller is fixed so the water moves instead. Propeller pumps have the advantage that they can deliver large amounts of water at low pressure (normally less than 10 mH2O). The reason for the low pressure is leakage that occurs between the two sides of the propeller (head and suck). On some pumps the flow rate can easily be varied by adjusting the angles of the pro-peller vanes. The propeller is normally installed in a vertical pipe, but it is also possible to place it in a horizontal pipe to create a flow.

Dry placed or submerged pumps

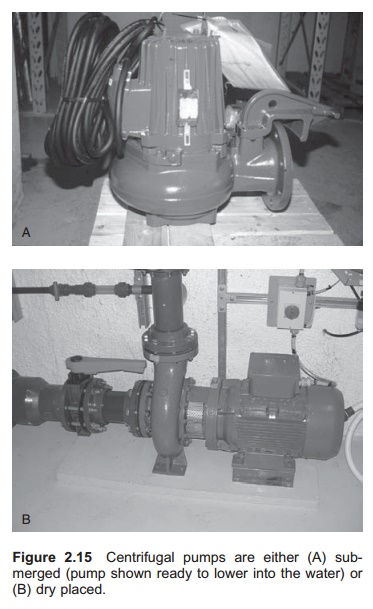

Centrifugal pumps can be dry placed, either above water level or in a dry well below water level. They can also be installed in the water as submerged pumps (Fig. 2.15).

A dry placed pump consists of a pump chamber with an impeller, a transfer shaft and an electric motor. On dry placed pumps the motor is cooled by a fan and on submerged pumps by water. Between the pump chamber and the motor there is a seal to prevent water leaking into the motor. Dry placed pumps may also be made self-suctioning by use of a specially designed impeller. Dry placed pumps are normally bolted to a rack that is fixed to the floor.

In a submerged pump the motor and the pump chamber are usually built together and encapsulated in one unit which is lowered into the water. As for dry placed pumps, it is important to have a good seal between the pump chamber and the motor. The whole must be watertight, to prevent water from entering the motor. The motor is cooled by the surrounding water and the encapsulating part can be equipped with cooling ribs to facilitate this.

Both dry placed and submerged pumps are com-monly used in aquaculture. The advantage with dry placed pumps is that maintenance is simple because it is easy to access the pump and pump parts. A dis-advantage could be that artificial cooling of the motor is necessary, needing a fan. If there are leak-ages in the inlet pipeline false air may be drawn in,causing cavitation in the pump and supersaturation of nitrogen, especially when using dry placed pumps standing above the water surface.

Related Topics