Chapter: Aquaculture Engineering : Water Transport

Change of water flow or pressure

Change of water flow or pressure

When choosing a pump it is important that the pump works as closely as possible to its construction point. What may then be done if the chosen pump does not fulfil this condition and cannot be changed?

Change of impeller (pump wheel)

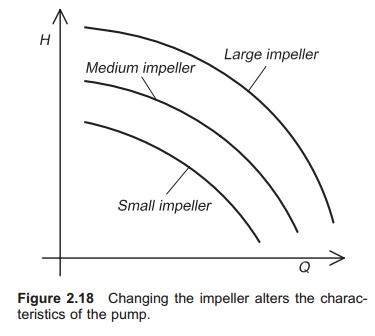

Most of the centrifugal pumps can be supplied with different impellers. By selecting an impeller of dif-ferent shape and diameter it is therefore possible to

change the pump characteristics (Fig. 2.18). In this way it is possible to find an impeller that is better adjusted to the working point of the pump, and better efficiency can be achieved.

The following connections can be used to show the pump performance when reducing or increas-ing the diameter of the impeller:

Q2/Q1= d2/d1

H2/H1=(d2/d1)2

P2/P1=(d2/d1)3

where:

d2=diameter of smallest impeller d1=diameter of largest impeller Q =flow rate

H =head

P =power requirement.

Example

The diameter of an impeller to a centrifugal pump is increased from 515 mm (d1) to 555 mm (d2). The flow rate in the first case was 700 l/s (Q1) and the head is 9 m (H1). Calculate the new flow rate (Q2) and the new head (H2).

Q2/Q1= d2/d1

Q2=1.08×700= 754 l/s

H2/H1=(d2/ d1)2

H2=9×1.16= 10.5 m

These equations are most reliable with a range of 20% increase/decrease in diameter, because large changes of the diameter of the impeller may alter pump geometry.

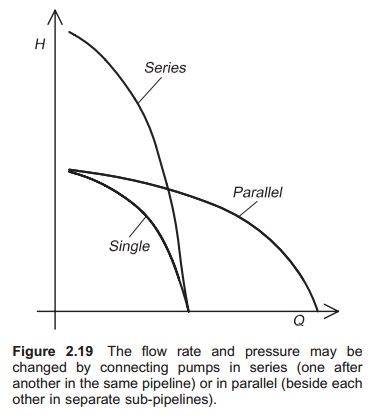

Connection of pumps

Pumps can be connected in series (one after another) or in parallel (beside each other). In this way the water flow and water pressure can be changed (Fig. 2.19). When pumps are connected in series, they are placed one after another in the same pipeline, so increasing the head while maintaining the same water flow. The inlet pressure of the second pump is the outlet pressure from the first pump so the pressure head is increased.

When pumps are connected in parallel, the main pipeline is divided into two sub-pipelines. One pump is placed in each sub-pipeline; these are then connected to the main pipeline. Parallel connection doubles the water flow, while the head remains constant.

High pressure pumps

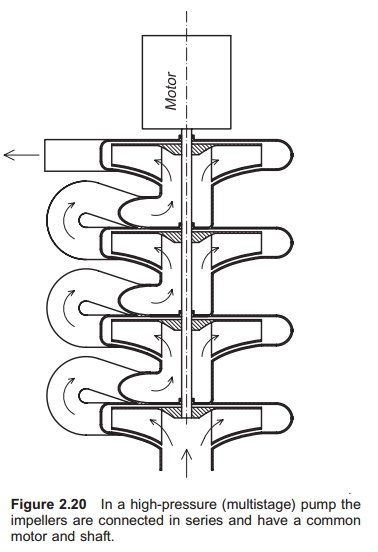

High pressure pumps are special types of centrifugal pumps that utilize a system of pumps connected in series (Fig. 2.20). In a high-pressure (multi-stage) pump the impellers are connected in series, and can share the same motor and shaft. The motor and shaft are of course larger than if a single impeller is used. When the water leaves the first impeller it is collected and directed into the centre of the next impeller and so on, and the head gradually increases depending on the number of impellers. This is possible through the design of the pump chamber. High-pressure pumps are used for instance for pumping groundwater from great depths or for other purposes where there is either a large head to be overcome or if a high water pres-sure is required.

Related Topics