Chapter: Mechanical : Metrology and Measurements : Thread Measurement

Thread Measurement

INTRODUCTION

Threads are of prime importance, they

are used as fasteners. It is a helical groove, used to transmit force and

motion. In plain shaft, the hole assembly, the object of dimensional control is

to ensure a certain consistency of fit. The performance of screw threads during

their assembly with nut depends upon a number of parameters such as the

condition of the machine tool used for screw cutting, work material and tool.

· Form

measurement includes

· Screw

thread measurement

· Gear

measurement

· Radius

measurement

· Surface

Finish measurement

· Straightness

measurement

· Flatness

and roundness measurements

Screw Thread

Measurement

Screw threads are used to transmit the power and

motion, and also used to fasten two components with the help of nuts, bolts and

studs. There is a large variety of screw threads varying in their form, by

included angle, head angle, helix angle etc. The screw threads are mainly

classified into 1) External thread 2) Internal thread.

Screw Thread

Terminology

Fig

3.3 Screw Thread

· Pitch

It is the distance measured parallel to

the screw threads axis between the corresponding points on two adjacent threads

in the same axial plane. The basic pitch is equal to the lead divided by the

number of thread starts.

· Minor diameter:

It is the diameter of an imaginary

co-axial cylinder which touches the roots of external threads.

· Major diameter:

It is the diameter of an imaginary

co-axial cylinder which touches the crests of an external thread and the root

of an internal thread.

· Lead:

The

axial distance advanced by the screw in one revolution is the lead.

· Pitch diameter:

It is the diameter at which the thread

space and width are equal to half of the screw thread

· Helix angle:

It

is the angle made by the helix of the thread at the pitch line with the axis.

The angle is measured in an axial plane.

· Flank angle:

It is the angle between the flank and a

line normal to the axis passing through the apex of the thread.

· Height of thread:

It is the distance measured radially

between the major and minor diameters respectively

· Addendum:

Radial distance between the major and

pitch cylinders for external thread. Radial distance between the minor and

pitch cylinder for internal thread.

· Dedendum:

It is the radial distance between the

pitch and minor cylinders for external thread. Also radial distance between the

major and pitch cylinders for internal thread.

Error in Thread

The errors in screw thread may arise

during the manufacturing or storage of threads. The errors either may cause in

following six main elements in the thread.

1) Major

diameter error

2) Minor

diameter error

3) Effective

diameter error

4) Pitch

error

5) Flank

angles error

6) Crest

and root error

1) Major

diameter error

It may cause reduction in the flank contact and interference

with the matching threads.

2)

Minor diameter error

It

may cause interference, reduction of flank contact.

3)

Effective diameter error

If the effective diameter is small the threads will

be thin on the external screw and thick on an internal screw.

4)

Pitch errors

If error in pitch, the total length of thread

engaged will be either too high or too small.

The

various pitch errors may classified into

1. Progressive

error

2. Periodic

error

3. Drunken

error

4. Irregular

error

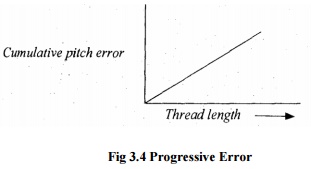

1) Progressive

error

The pitch of the thread is uniform but

is longer or shorter its nominal value and this is called progressive.

Causes

of progressive error:

1. Incorrect

linear and angular velocity ratio.

2. In

correct gear train and lead screw.

3. Saddle

fault.

4. Variation

in length due to hardening.

2)

Periodic error

These

are repeats itself at regular intervals along the thread

Causes

of periodic error:

1.

Un uniform tool work velocity ratio.

2. Teeth

error in gears.

3. Lead

screw error.

4. Eccentric

mounting of the gears.

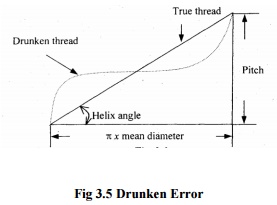

3)Drunken

error

Drunken

errors are repeated once per turn of the thread in a drunken thread. In Drunken

thread the pitch measured parallel to the thread axis. If the thread is not cut

to the true helix the drunken thread

error will form.

Fig

3.5 Drunken Error

4)

Irregular errors

It

is vary irregular manner along the length of the thread.

Irregular

error causes:

1. Machine

fault.

2. Non-uniformity

in the material.

3. Cutting

action is not correct.

4. Machining

disturbances.

Effect

of pitch errors

·

Increase the effective diameter of the

bolt and decreases the diameter of nut.

·

The functional diameter of the nut will

be less.

·

Reduce the clearance.

·

Increase the interference between mating

threads.

Measurement of various

elements of Thread

To find out the accuracy of a screw thread it will

be necessary to measure the following:

1. Major

diameter.

2. Minor

diameter.

3. Effective

or Pitch diameter.

4. Pitch

5. Thread

angle and form

1.

Measurement of major diameter:

The

instruments which are used to find the major diameter are by

·

Ordinary micrometer

·

Bench micrometer.

·

Ordinary micrometer

The ordinary micrometer is quite

suitable for measuring the external major diameter. It is first adjusted for

appropriate cylindrical size (S) having the same diameter

(approximately).Thisge processsetting’is. Afterknown

takias‘ micrometer is set on the major diameter of

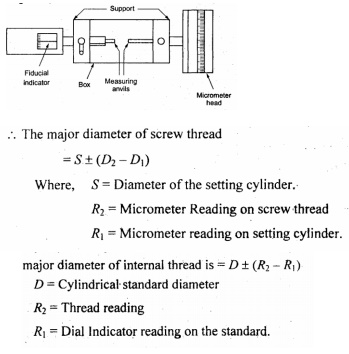

· Bench micrometer

For

getting the greater accuracy the bench micrometer is used for measuring the

major diameter. In this process the variation in measuring Pressure, pitch

errors are being neglected. The fiducial indicator is used to ensure all the

measurements are made at same pressure. The instrument has a micrometer head

with a vernier scale to read the accuracy of 0.002mm. Calibrated setting

cylinder having the same diameter as the major diameter of the thread to be

measured is used as setting standard. After setting the standard, the setting

cylinder is held between the anvils and the reading is taken. Then the cylinder

is replaced by the threaded work piece and the new reading is taken.

Fig

3.6 Bench Micrometer

· Measurement of the major diameter of an Internal

thread

The Inter thread major diameter is usually measured by thread comparator fitted with ball-ended styli. First the Instrument is set for a cylindrical reference having the root of spring under pressure. For that the new reading is taken.

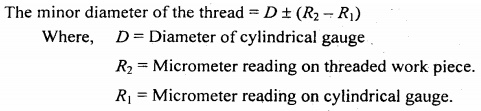

2.

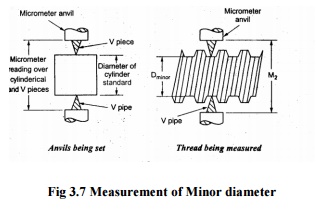

Measurement of Minor diameter

The minor diameter is measured by a

comparative method by using floating carriage diameter measuring machine and

small V pieces which make contact with the root of the thread. These V pieces

are made in several sizes, having suitable radii at the edges. V pieces are

made of hardened steel. The floating carriage diameter-measuring machine is a

bench micrometer mounted on a carriage.

Fig

3.7 Measurement of Minor diameter

· Measurement process

The

threaded work piece is mounted between the centers of the instrument and the V

pieces are placed on each side of the work piece and then the reading is noted.

After taking this reading the work piece is then replaced by a standard

reference cylindrical setting gauge.

·

Measurement of Minor diameter of

Internal threads

The Minor diameter of Internal threads are measured

by

1. Using

taper parallels

2. Using

Rollers.

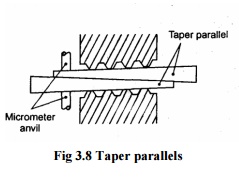

· Using taper parallels

For

diameters less than 200mm the use of Taper parallels and micrometer is very

common. The taper parallels are pairs of wedges having reduced and parallel

outer edges. The diameter across their outer edges can be changed by sliding

them over each other.

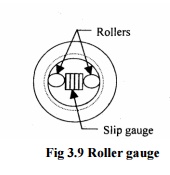

· Using rollers

For

more than 20mm diameter this method is used. Precision rollers are inserted

inside the thread and proper slip gauge is inserted between the rollers. The

minor diameter is then the length of slip gauges plus twice the diameter of

roller.

3.

Measurement of effective diameter

Effective diameter measurement is carried out by

following methods.

1. One

wire,

2. Two

wires, or

3. Three

wires method.

4. Micrometer

method.

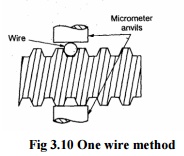

a) One wire method

The only one wire is used in this method. The wire

is placed between two threads at one side and on the other side the anvil of

the measuring micrometer contacts the crests. First the micrometer reading dl

is noted on a standard gauge whose dimension is approximately same to be

obtained by this method

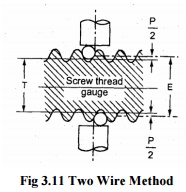

b) Two wire method

Two-wire method of measuring the effective diameter

of a screw thread is given below. In this method wires of suitable size are

placed between the standard and the micrometer anvils. First the micrometer

reading is taken and let it be R. Then the standard is replaced by the screw

thread to be measured and the new reading is taken.

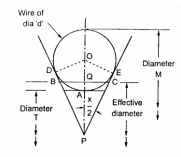

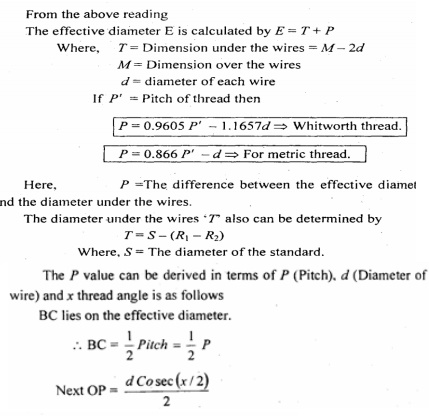

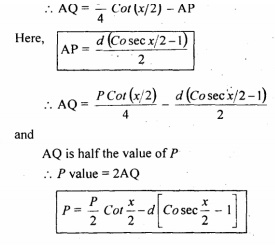

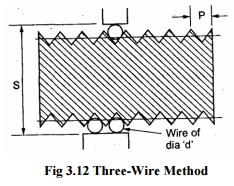

c) Three-Wire method

The three-wire method

is the accurate method. In this method three wires of equal and precise

diameter are placed in the groves at opposite sides of the screw. In this one

wire on one side and two on the other side are used. The wires either may held

in hand or hung from a stand. This method ensures the alignment of micrometer

anvil faces parallel to the thread axis.

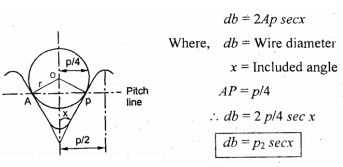

· BEST WIRE SIZE-DEVIATION

Best wire diameter is that may contact

with the flanks of the thread on the pitch line. The figure shows the wire

makes contact with the flanks of the thread on the pitch.

Hence

best wire diameter,

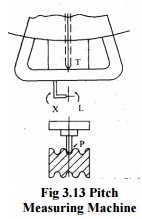

4.

Pitch measurement

The

most commonly used methods for measuring the pitch are

1. Pitch

measuring machine

2.

Tool

maker’s microscope

3. Screw

pitch gauge

· Pitch

measuring machine

The principle of the method of measurement is to

move the stylus along the screen parallel to the axis from one space to the

next. The pitch-measuring machine provides a relatively simple and accurate

method of measuring the pitch. Initially the micrometer reading is near the

zero on the scale, the indicator is moved along to bring the stylus, next the

indicator adjusted radially until the stylus engages between the thread flank

and the pointer ‘K’ is opposite Measuring Machine line in its index mark a

small movement is necessary in the micrometer and then the reading is taken

next. The stylus is moved along into the next space by rotation of the

micrometer and the second reading is taken. The difference between these two-

measured readings is known as the pitch of the thread.

•

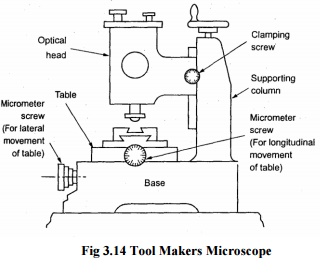

Tool makers microscope

Working

Worktable is placed on the base of the base of the

instrument. The optical head is mounted on a vertical column it can be moved up

and down. Work piece is mounted on a glass plate. A light source provides

horizontal beam of light which is reflected from a mirror by 900 upwards

towards the table. Image of the outline contour of the work piece passes

through the objective of the optical head. The image

is projected by a system of three prisms to a ground glass screen. The

measurements are made by means of cross lines engraved on the ground glass

screen. The screen can be rotated through 360°. Different types of graduated

screens and eyepieces are used.

·

Applications

o Linear

measurements.

o Measurement of pitch of the screw. o Measurement

of pitch diameter.

o Measurement of thread angle. o Comparing

thread forms.

o Centre

to center distance measurement.

o Thread

form and flank angle measurement

· Thread form and flank angle measurement

The optical projections are used to

check the thread form and angles in the thread. The projectors equipped with

work holding fixtures, lamp, and lenses. The light rays from the lens are

directed into the cabinet and prisons and mirrors. The enlarged image of thread

is drawn. The ideal and actual forms are compared for the measurement.

Related Topics