Chapter: Mechanical : Metrology and Measurements : Thread Measurement

Gear Measurement

GEAR MEASUREMENT

Introduction

Gear is a mechanical drive which

transmits power through toothed wheel. In this gear drive, the driving wheel is

in direct contact with driven wheel. The accuracy of gearing is the very

important factor when gears are manufactured. The transmission efficiency is

almost 99 in gears. So it is very important to test and measure the gears

precisely. For proper inspection of gear, it is very important to concentrate

on the raw materials, which are used to manufacture the gears, also very

important to check the machining the blanks, heat treatment and the finishing

of teeth. The gear blanks should be tested for dimensional accuracy and tooth

thickness for the forms of gears.

The

most commonly used forms of gear teeth are

1. Involute

2. Cycloidal

The involute gears also called as

straight tooth or spur gears. The cycloidal gears are used in heavy and impact

loads. The involute rack has straight teeth. The involute pressure angle is

either 20° or 14.5°.

Types of gears

1. Spur gear

Cylindrical gear whose tooth traces is

straight line. These are used for transmitting power between parallel shafts.

2.

Spiral gear

The tooth of

the gear traces curved lines.

3.

Helical gears

These gears used to transmit the power

between parallel shafts as well as nonparallel and non-intersecting shafts. It

is a cylindrical gear whose tooth traces is straight line.

4.

Bevel gears:

The tooth traces are straight-line

generators of cone. The teeth are cut on the conical surface. It is used to

connect the shafts at right angles.

5.

Worm and Worm wheel:

It

is used to connect the shafts whose axes are non-parallel and non-intersecting.

6.

Rack and Pinion:

Rack

gears are straight spur gears with infinite radius.

Gear terminology

1. Tooth profile

It

is the shape of any side of gear tooth in its cross section.

2.

Base circle

It is the circle of gear from which the involute

profile is derived. Base circle diameter Pitch circle diameter x Cosine of

pressure angle of gear

3.

Pitch circle diameter (PCD)

The diameter of a circle which will produce the same

motion as the toothed gear wheel.

4.

Pitch circle

It is the imaginary circle of gear that rolls

without slipping over the circle of its matiug gear.

5.

Addendum circle

The

circle coincides with the crests (or) tops of teeth.

6.

Dedendum circle (or) Root circle

This

circle coincides with the roots (or) bottom on teeth.

7.

Pressure angle (a)

It is the angle making by the line of action with

the common tangent to the pitch circles of mating gears.

8.

Module(m)

It is the ratio of pitch circle diameter to the

total number of teeth. Where, d = Pitch circle diameter. n = Number f teeth.

9.

Circular pitch

It is the distance along the pitch circle between

corresponding points of adjacent teeth.

10.

Addendum

Radial

distance between tip circle and pitch circle. Addendum value = 1 module.

11

Dedendum

Radial

distance between itch circle and root circle,

Dedendum

value = 1 .25module.

12.

Clearance (C)

Amount of distance made by the tip of one gear with

the root of mating gear. Clearance = Difference between Dedendum and addendum

values.

13.

Blank diameter:

The

diameter of the blank from which gear is out. Blank diameter = PCD + 2m

14.

Face:

Part

of the tooth in the axial plane lying between tip circle and pitch circle.

15.

Flank:

Part

of the tooth lying between pitch circle and root circle.

16.

Top land:

Top

surface of a tooth.

17.

Lead angle

The

angle between the tangent to the helix and plane perpendicular to the axis of

cylinder.

18. Backlash:

The

difference between the tooth thickness and the space into which it meshes. If

we assume the tooth thickness as t and width ‘ t

Gear errors

1.

Profile error:

- The maximum distance of any point on the tooth profile form to the

design profile.

2. Pitch

error: - Difference between actual and design pitch

3. Cyclic

error: - Error occurs in each revolution of gear

4.

Run out:

- Total range of reading of a fixed indicator with the contact points applied

to a surface rotated, without axial movement, about a fixed axis.

5. Eccentricity:

- Half the radial run out

6.

Wobble:

- Run out measured parallel to. the axis of rotation at a specified distance

from the axis

7.

Radial run out:

- Run out measured along a perpendicular to the axis of rotation.

8.

Undulation:

- Periodical departure of the actual tooth surface from the design surface.

9. Axial

run out: - Run out measured parallel to the axis of

rotation at a speed.

10.

Periodic error:

-Error occurring at regular intervals.

Gear Measurement

The Inspection of the gears consists of

determine the following elements in which manufacturing error may be present.

1. Runout.

2. Pitch

3. Profile

4. Lead

5. Back

lash

6. Tooth

thickness

7. Concentricity

8. Alignment

1. Runout:

It means eccentricity in the pitch

circle. It will give periodic vibration during each revolution of the gear.

This will give the tooth failure in gears. The run out is measured by means of

eccentricity testers. In the testing the gears are placed in the mandrel and

the dial indicator of the tester possesses special tip depending upon the

module of the gear and the tips inserted between the tooth spaces and the gears

are rotated tooth by tooth and the variation is noted from the dial indicator.

2.

Pitch measurement:

There

are two ways for measuring the pitch.

1. Point

to point measurement (i.e. One tooth point to next toot point)

2. Direct

angular measurement

1. Tooth

to Tooth measurement

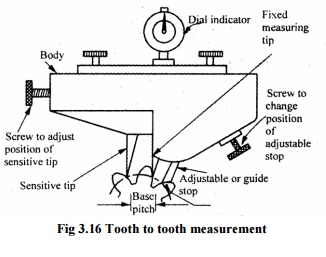

Fig 3.16 Tooth to tooth

measurement

The instrument has three

tips. One is fixed measuring tip and the second is sensitive tip, whose

position can be adjusted by a screw and the third tip is adjustable or guide

stop. The distance between the fixed and sensitive tip is equivalent to base

pitch of the gear. All the three tips are contact the tooth by setting the

instrument and the reading on the dial indicator is the error in the base

pitch.

2. Direct Angular Measurement

It is the simplest method

for measuring the error by using set dial gauge against a tooth. in this method

the position of a suitable point on a tooth is measured after the gear has been

indexed by a suitable angle. If the gear is not indexed through the angular

pitch the reading differs from the original reading. The difference between

these is the cumulative pitch error.

3. Profile checking

The methods used for

profile checking is

1. Optical projection

method.

2. Involute measuring

machine.

1.

Optical projection method:

The profile of the gear

projected on the screen by optical lens and then projected value is compared

with master profile.

2. Involute

measuring machine:

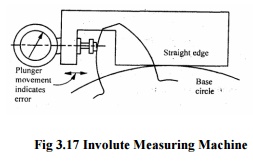

Fig

3.17 Involute Measuring Machine

In this method the gear is held on a

mandrel and circular disc of same diameter as the base circle of gear for the

measurement is fixed on the mandrel. After fixing the gear in the mandrel, the

straight edge of the instrument is brought in contact with the base circle of

the disc. Now, the gear and disc are rotated and the edge moves over the disc

without sleep. The stylus moves over the tooth profile and the error is

indicated on the dial gauge.

4. Lead checking:

It is checked by lead

checking instruments. Actually lead is the axial advance of a helix for one

complete turn. The lead checking instruments are advances a probe along a tooth

surface, parallel to the axis when the gear rotates.

5. Backlash checking:

Backlash is the

distance through which a gear can be rotated to bring its nonworking flank in

contact with the teeth of mating gear. Numerical values of backlash are

measured at the tightest point of mesh on the pitch circle.

There are two types of backlash

1. Circumferential

backlash

2. Normal

backlas

The determination of

backlash is, first one of the two gears of the pair is locked, while other is

rotated forward and backward and by the comparator the maximum displacement is

measured. The stylus of comparator is locked near the reference cylinder and a

tangent to this is called circular backlash.

6. Tooth thickness measurement:

Tooth thickness is

generally measured at pitch circle and also in most cases the chordal thickness

measurement is carried out i.e. the chord joining the intersection of the tooth

profile with the pitch circle.

The

methods which are used for measuring the gear tooth thickness is

a) Gear

tooth vernier caliper method (Chordal thickness method)

b) Base

tangent method.

c) Constant

chord method.

d) Measurement

over pins or balls.

a) Gear tooth vernier method

In gear tooth vernier

method the thickness is measured at the pitch line. Gear tooth thickness varies

from the tip of the base circle of the tooth, and the instrument is capable of

measuring the thickness at a specified position on the tooth. The tooth vernier

caliper consists of vernier scale and two perpendicular arms. In the two

perpendicular arms one arm is used to measure the thickness and other arm is

used to measure the depth. Horizontal vernier scale reading gives chordal

thickness (W) and vertical vernier scale gives the chordal addendum. Finally

the two values compared.

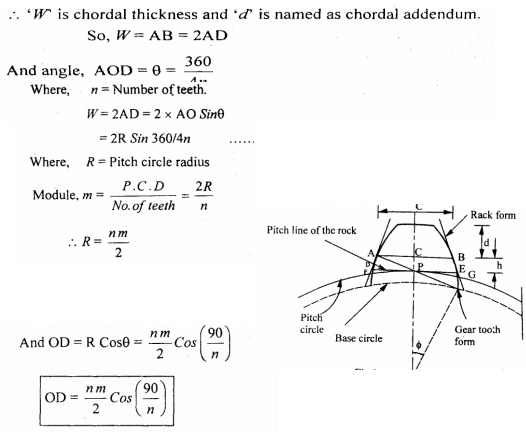

The theoretical values

of W and d can be found out by considering one tooth in the gear and it can be

verified. In fig noted that w is a chord ADB and tooth thickness is specified

by AEB. The distance d is noted and adjusted on instrument and it is slightly

greater than addendum CE.

Vernier method like the

chordal thickness and chordal addendum are dependent upon the number of teeth.

Due to this for measuring large number of gears different calculations are to

be made for each gear. So these difficulties are avoided by this constant chord

method.

b) Measurement over Rolls or balls

A very good and

convenient method for measuring thickness of gear. In this method two or three

different size rollers are used for checkup the vibrations at several places on

the tooth.

7. Measurement of concentricity

In setting of gears the

centre about which the gear is mounded should be coincident with the centre

from which the gear is generated. It is easy to check the concentricity of the

gear by mounting the gear between centres and measuring the variation in height

of a roller placed between the successive teeth. Finally the variation in

reading will be a function of the eccentricity present.

8. Alignment checking

It is done by placing a

parallel bar between the gear teeth and the gear being mounted between centres.

Finally the readings are taken at the two ends of the bar and difference in

reading is the misalignment.

Parkinson Gear Tester

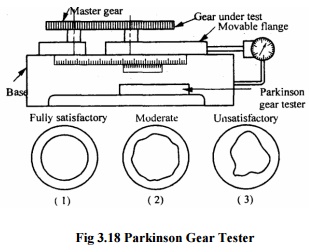

Working principle

The master gear is

fixed on vertical spindle and the gear to be tested is fixed on similar spindle

which is mounted on a carriage. The carriage which can slide either side of

these gears are maintained in mesh by spring pressure. When the gears are

rotated, the movement of sliding carriage is indicated by a dial indicator and

these variations arc is measure of any irregularities. The variation is

recorded in a recorder which is fitted in the form of a waxed circular chart.

In the gears are fitted on the mandrels and are free to rotate without

clearance and the left mandrel move along the table and the right mandrel move

along the spring-loaded carriage.

Fig

3.18 Parkinson Gear Tester

The two spindles can be adjusted so that the axial

distance is equal and a scale is attached to one side and vernier to the other,

this enables center distance to be measured to within 0.025mm. If any errors in

the tooth form when gears are in close mesh, pitch of concentricity of pitch

line will cause a variation in center distance from this movement of carriage

as indicated to the dial gauge will show the errors in the gear test. The

recorder also fitted in the form of circular or rectangular chart and the

errors are recorded.

·

Limitations of Parkinson gear tester:

1. Accuracy±0.001mm

2. Maximum

gear diameter is 300mm

3. Errors

are not clearly identified:

4. Measurement

dependent upon the master gear.

5. Low

friction in the movement of the floating carriage.

Related Topics