Chapter: Mechanical : Metrology and Measurements : Thread Measurement

Roundness Measurement

ROUNDNESS MEASUREMENTS

Roundness is defined as a condition of a

surface of revolution. Where all points of the surface intersected by any plane

perpendicular to a common axis in case of cylinder and cone.

Devices used for

measurement of roundness

1) Diametral

gauge.

2) Circumferential

conferring gauge => a shaft is confined in a ring gauge and rotated against

a set indicator probe.

3) Rotating

on center

4) V-Block

5) Three-point

probe.

6) Accurate

spindle.

1.

Diametral method

The measuring plungers are located 180°

a part and the diameter is measured at several places. This method is suitable

only when the specimen is elliptical or has an even number of lobes. Diametral

check does not necessarily disclose effective size or roundness. This method is

unreliable in determining roundness.

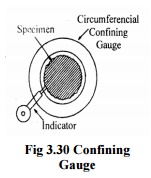

1. Circumferential

confining gauge

Fig.

shows the principle of this method. It is useful for inspection of roundness in

production. This method requires highly accurate master for each size part to

be measured. The clearance between part and gauge is critical to reliability.

This technique does not allow for the measurement of other related geometric

characteristics, such as concentricity, flatness of shoulders etc.

3. Rotating on centers

The

shaft is inspected for roundness while mounted on center. In this case,

reliability is dependent on many factors like angle of centers, alignment of

centres, roundness and surface condition of the centres and centre holes and

run out of piece. Out of straightness of the part will cause a doubling run out

effect and appear to be roundness error.

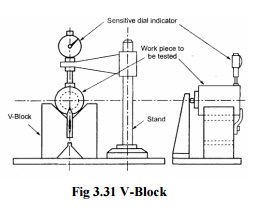

2. V-Block

The

set up employed for assessing the circularity error by using V Block is shown

in fig.

The

V block is placed on surface plate and the work to be checked is placed upon

it. A diameter indicator is fixed in a stand and its feeler made to rest

against the surface of the work. The work is rotated to measure the rise on

fall of the workpiece. For determining the number of lobes on the work piece,

the work piece is first tested in a 60° V-Block and then in a 90° V-Block. The

number of lobes is then equal to the number of times the indicator pointer

deflects through 360° rotation of the work piece.

Limitations

a)

The circularity error is greatly by affected by the following factors.

(i) If

the circularity error is i\e, then it is possible that the indicator shows no

variation.

(ii) Position

of the instrument i.e. whether measured from top or bottom.

(iii) Number

of lobes on the rotating part.

b) The

instrument position should be in the same vertical plane as the point of

contact of the part with the V-block.

c) A

leaf spring should always be kept below the indicator plunger and the surface

of the part.

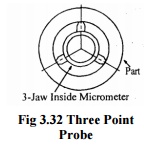

5.

Three point probe

The

fig. shows three probes with 120° spacing is very, useful for determining

effective size they perform like a 60° V-block. 60° V-block will show no error

for 5 a 7 lobes magnify the error for 3-lobed parts show partial error for

randomly spaced lobes.

Roundness measuring

spindle

There are following two types of spindles used.

1.Overhead spindle

Part is fixed in a staging plat form and

the overhead spindle carrying the comparator rotates separately from the part.

It can determine roundness as well as camming (Circular flatness). Height of

the work piece is limited by the location of overhead spindle. The

concentricity can be checked by extending the indicator from the spindle and

thus the range of this check is limited.

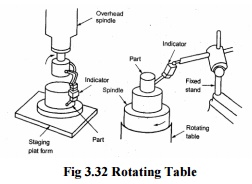

2.Rotating table

Spindle is integral with the table and rotates along

with it. The part is placed over the spindle and rotates past a fixed

comparator

Fig 3.32 Rotating Table

Roundness measuring

machine

Roundness is the property of a surface of revolution,

where all points on the surface are equidistant from the axis. The roundness of

any profile can be specified only when same center is found from which to make

the measurements. The diameter and roundness are measured by different method

and instruments. For measurement of diameter it is done statically, for

measuring roundness, rotation is always necessary. Roundness measuring

instruments are two types.

1. Rotating

pick up type.

2. Turn

table type.

These are accurate, speed and reliable

measurements. The rotating pick up type the work piece is stationary and the

pickup revolved. In the turn table the work piece is rotated and pick up is

stationery. On the rotating type, spindle is designed to carry the light load

of the pickup. The weight of the work piece, being stationary and is easy to

make. In the turn table type the pickup is not associated with the spindle.

This is easier to measure roundness. Reposition the pickup has no effects on

the reference axis.

The pickup converts the circuit movement

of the stylus into electrical signal, which is processed and amplified and fed

to a polar recorder. A microcomputer is incorporated with integral visual

display unit and system is controlled from compact keyboards, which increases

the system versatility, scope and speed of analysis. System is programmed to

access the roundness of work piece with respect to any four of the

internationality recognized reference circles. A visual display of work piece

profile can be obtained. Work piece can be assessed over a circumference, and

with undercut surface or an interrupted surface with sufficient data the

reference circle can be fitted to the profile. The program also provides

functions like auto centering, auto ranging, auto calibration and

concentricity.

Modern Roundness

Measuring Instruments

This is based on use of microprocessor to provide

measurements of roundness quickly and in a simple way; there is no need of

assessing out of roundness. Machine can do centering automatically and

calculate roundness and concentricity, straightness and provide visual and

digital displays. A computer is used to speed up calculations and provide the

stand reference circle.

(i) Least square circle

The sum of the squares

of a sufficient no. of equally spaced radial ordinates measured from the circle

to the profile has minimum value. The center of such circle is referred to as

the least square center. Out of roundness is defined as the radial distance of

the maximum peak from the circle (P) plus the distance of the maximum valley

from this circle.

(ii) Minimum zone or Minimum radial

separation circle

These are two

concentric circles. The value of the out of roundness is the radial distance

between the two circles. The center of such a circle is termed as the minimum

zone center. These circles can be found by using a template.

(iii) Maximum inscribed circle

This is the largest

circle. Its center and radius can be found by trial and error by compare or by

template or computer. Since V = 0 there is no valleys inside the circle.

(iv)Minimum circumscribed circles

This is the smallest

circle. Its center and radius can be found by the previous method since P = 0

there is no peak outside the circle. The radial distance between the minimum

circumscribing circle and the maximum inscribing circle is the measure of the

error circularity. The fig shows the trace produced by a recording instrument.

This trace to draw concentric circles on the polar

graph which pass through the maximum and minimum points in such way that the

radial distance be minimum circumscribing circle containing the trace or the n

inscribing circle which can fitted into the trace is minimum. The radial

distance between the outer and inner circle is minimum is considered for

determining the circularity error. Assessment of roundness can be done by

templates. The out off roundness is defined as the radial distance of the

maximum peak (P) from the least square circle plus the distance of the maximum

valley (V) from the least square circle. All roundness analysis can be

performed by harmonic and slope analysis.

Related Topics