Chapter: Mechanical : Metrology and Measurements : Thread Measurement

Radius Measurement

RADIUS MEASUREMENT

In

radius measurement we are going see about two methods namely.

1

Radius of circle and

2. Radius

of concave surface

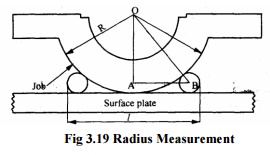

1.Radius of circle

This radius measurement

requires the use of vernier caliper, C- Clamp, surface plate and two pins. This

method is very much use in measuring the cap of bearing. Initially the job is

fixed on surface plate with the help of C-clamp. So that the central position

of the circular part is touch with the surface plate. Next the two balls are

placed on both side of the work and using the vernier caliper readings are

taken.

Let, R = Radius of job,

I = The reading between two balls

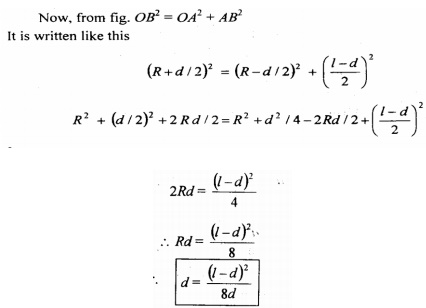

2. Radius of concave surface

Here

there are two methods

1.Edges are well defined.

2.Edges are rounded up

Edges are well defined

In this method radius

is calculated by using surface plate, height gauge, angle plate,C-clamp and

slip gauges. First the Job placed on the surface plate and then by using depth

micrometer the depth is measured and it is h. Next in such a way that cavity is

resting against an angle plate and the part is clamped in this position. By

using a height gauge edge to edge size of hole is measured and this is diameter

of d.

When

cavities are rounded up the radius is measured by depth micrometer

and slip gauges. First the width of the micrometer

is measured by slip gauges and

it is let

‘ d’. Then

it is placed

in t

touches the base. From this condition the reading is

noted and it be h and the

radius is measured by using the formula

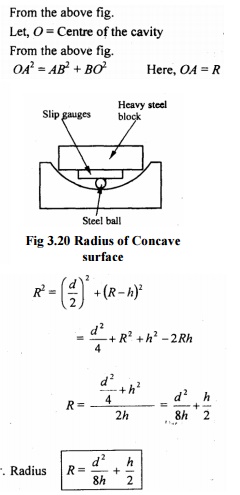

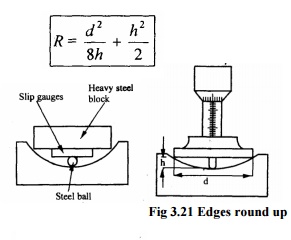

2) Edges are rounded up

When cavities are

rounded up the radius is measured by depth micrometer and slip gauges. First

the width of the micrometer is measured by slip gauges and it is let ‘d’. Then

placed in the cavity and measuring tip is lowered down to touches the base.

From this condition the reading is noted and it be h and the radius is measured

by using the formula

Related Topics