Chapter: Mechanical : Total Quality Management (TQM) : Principles

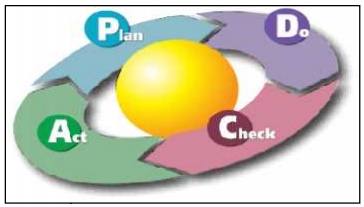

The PDCA Cycle

THE PDCA CYCLE

PROBLEM

SOLVING METH OD

1. IDENTIFY THE OPPORT UNITY

├ś Identify

the Problem

┬¦ Pareto

analysis of external a larm signals.

┬¦ Pareto

analysis of internal alarm signals.

┬¦ Proposals

from key insiders.

┬¦ Proposals

from suggestion schemes.

┬¦ Field study

of userŌĆÖs needs.

┬¦ Comments

of key people ou tside the organization.

┬¦ Customer

surveys.

┬¦ Employee

surveys.

┬¦ Brainstorming

by work grou ps.

├ś Form the

Team

┬¦ Team

should be selected.

┬¦ Goals and

milestones are es tablished. ├ś Define

the Scope.

Criteria

for a good problem sta tement is as follows

┬¦ It

clearly describes the prob lem.

┬¦ It states

the effect.

┬¦ It

focuses on what is known, unknown etc.

┬¦ It

emphasizes the impact on the customer.

2. ANALYZE THE CURRENT PROCESS

The

objective is to understand the process and how it is currently performed.

Step 1 :

The team to develop a pr ocess flow diagram.

Step 2 :

The target performance m easures are defined.

Step 3 : Collection of all

available data and information.

Common items of data and

information are

1. Customer information

2. Design information

3. Process information

4. Statistical information

5. Quality information

6. Supplier information

3.

DEVELOP THE OPTIMAL SOLUTION(S)

This phase has the objective of establishing potential and

feasible solutions and recommending the best solution to improve the process.

├ś Creativity

plays the major role, and brainstorming is the principal technique.

├ś There are

three types of creativity:

┬¦ Create

new processes

┬¦ Combine

different processes

┬¦ Modify

the existing process

4.

IMPLEMENT CHANGES

This phase has the objective of preparing the implementation

plan, obtaining approval and implementing the process improvements.

├ś Approval

of the quality council.

├ś Obtain

the advice and consent of departments, functional areas, teams, individuals

etc.

├ś Monitor

the activity.

5. STUDY

THE RESULTS

This phase has the objective of monitoring and evaluating the

change by tracking and studying the effectiveness of the improvement efforts.

6.

STANDARDIZE THE SOLUTION

├ś Institutionalize by positive control of the

process.

├ś The quality peripherals ŌĆō the

system, environment and supervision must be certified. ├ś Operators must be certified.

7. PLAN

FOR THE FUTURE

The

objective is to achieve improved level of process performance.

├ś Regularly

conduct reviews of progress by the quality council.

├ś Establish

the systems to identify area for future improvements.

├ś Track

performance with respective internal & external customers.

├ś TQM tools

and techniques are used to improve quality, delivery and cost.

PDSA CYCLE (OR DEMING WHEEL)

The basic Plan ŌĆō Do ŌĆō Study ŌĆō Act cycle was originally developed by W alter A. Shewart. But it was popularized by Edward Deming and thatŌĆÖs why it is often called the Demi ng Cycle or Deming Wheel. It is an effective continuo us improvement technique.

The PDSA Cycle

What is PDSA Cycle?

PDSA stands for Plan, D o, Study, and Act. It is a model for

testing ideas that you think may

create

improvement.

┬Ę

It is an extremely practical, common sense based

approach that is easy to understand.

┬Ę

It can be used to test ideas for improvement

quickly and easily based on existing ideas, research, feedback, theory, review,

audit, etc.

┬Ę

It encourages starting with small changes, which

can build into large improvements in the service through successive quick

cycles of change.

┬Ę

Illustrates the PDSA cycle.

Phases of PDSA Cycle

The four phases of PDSA cycle and their descriptions are

presented in Table.

Phases of PDSA Cycle

Phases : Description

1.

Plan

ŌĆó Define the

problem

ŌĆó Analyze the causes and draft an action plan for

solving the problem. ŌĆó Determine the quality objectives and the critical

factors.

ŌĆó Define the

performance indicators.

ŌĆó Collect and analyze the necessary process data. ŌĆó

Generate possible solutions

ŌĆó Select

the most feasible solution; and work it out.

2. Do

ŌĆó First,

implement the plan on a limited scale or conduct an experiment to test the

proposed improvement. Collection data is hereby essential.

ŌĆó Train all

involved employees in the use of quality improvement methods and techniques.

ŌĆó Describe

the process which is considered for improvement and form project teams to lead

the process.

3. Check

ŌĆó Evaluate

the trial project with the performance indicators.

ŌĆó Verify

whether the improvement has been successful or not.

4. Act

ŌĆó Act to

implement proven improvements. The choices are: introduce the plan, adjust or

reject it.

ŌĆó The

improvements are documented in standard procedures so all employees are well-informed

on how to handle in future.

ŌĆó Usually,

the cycle will be repeated under the different circumstances and conditions to

test how consistent the results are.

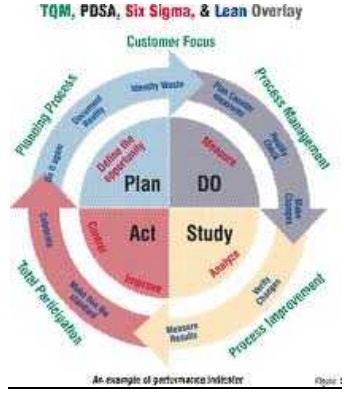

Continuous

Process Improvement Cycle Using PDCA

The relationship between the PDSA

cycle and eleven steps to continuous process improvement are illustrated in

figure.

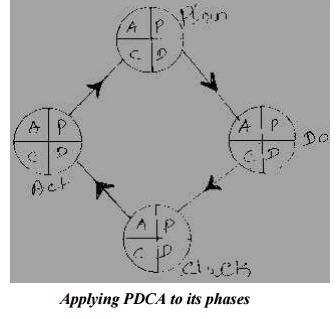

Each phase of the PDCA cycle must undergo its own PDCA cycle

for further improvements, as shown in figure.

Benefits

of the PDSA Cycle

The

benefits of the PDSA cycle can be experienced in the following areas:

┬Ę

Daily routine management ŌĆō for the

individual and / or the team.

┬Ę

Problem-solving process.

┬Ę

Project management

┬Ę

Continuous development

┬Ę

Vendor development

┬Ę

Human resources development

┬Ę

New product developmen t

┬Ę

Process trials

Related Topics