Chapter: Mechanical : Total Quality Management (TQM) : Principles

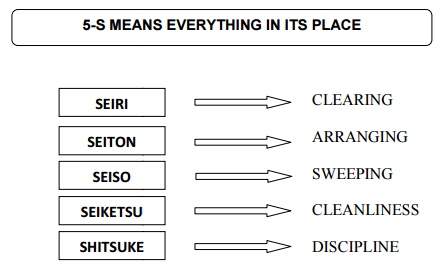

5-S: Housekeeping

5-S: HOUSEKEEPING

Ø There can

be no TQM without 5-S.

Ø A dirty

factory cannot produce quality products.

Ø Clutter

hides problems. A neat workplace promotes easy discovery of abnormalities.

The First

S : SEIRI : CLEARING

Factory

Floor

• Machines to be scrapped

• Rejected material

• Expired goods

• Broken tools, pallets, bins, trolleys.

• Old notices

Office

• Used / Broken pens

• Useless paper

• Old diaries

• Broken furniture’s

Home

• Broken toys

• Old clothes

• Broken suitcases

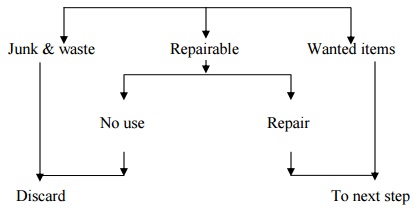

Flow

Chart :

Separating

the wanted and unwanted

Consequences

of not practicing SEIRI

Ø The

unwanted clutters up the place and the wanted are hard to find.

Ø Every

place can only hold so much.

Ø Clutter

sometimes causes misidentification.

The Second S : SEITON : ARRANGING

Arrange everything in proper order so that it can be easily picked up for use.

Factory

Floor

• Unlabelled tool crib

• Cluttered shelves lockers etc.

• Stores – no clear location system.

• Things on the floor

Office

• Unlabelled file cabinet

• Cluttered drawer, shelves, book cases, Tables

• Records & documents Not arranged well

• File heaps and papers

Home

• Clutter

• No orderly arrangement in the rooms

Consequences

of not practicing SEITON

Ø Things

are seldom available when needed.

Ø Items

are “lost’ in stores.

Ø Items –

defectives and good ones get mixed up.

Ø Accidents

or near-accidents occur due to clutter.

Ø Visual

control of the shop floor is not possible.

Ø Sometimes,

production is lost because an item required is available but cannot be found.

Ø In some

offices, Critical Excise records or tax records may not be traceable. This can

lead to finance loss, prosecution or embarrassment.

The Third S : SEISO : SWEEPING

Sweep your workplace thoroughly so that there is

no dust anywhere.

Factory

Floor

• Dirty machines

• Dust on product parts, R.Mtls.

• Dirty jigs, fixtures

• Dirty walls, roofs

• Littered floor

Office

• Dirty table & furniture

• Dirty office equipments

• Littered floor

• Dirty windows

Home

• Dirty furniture, floor, window, grills,

bookshelves.

Consequences

of not practicing SEISO

Ø Most

machines are affected by dust & dirt and hence their performance may go

down.

Ø Dust and

dirt on products, materials, packing boxes etc. will affect either their

performance quality or their aesthetic look.

Unpleasant to work in.

The

Fourth S : SEIKETSU : CLEANLINESS

Washing with a strong overtone of keeping things

disinfected as well as free of hazardous chemicals.

Factory

Floor

• Handling hazardous Chemicals

• Control of

fumes, hazardous dust.

• Disinfecting,

Personal hygiene

Office

• Free of pests

• Personal hygiene

Home

• Pest control

• Personal hygiene

Consequences

of not practicing SEIKETSU

Ø Good

health and safety require the practice of Seiketsu.

Ø Hazardous

chemicals, dusty chemicals, fumes etc. can make it a dangerous place to work

in.

Ø Washing

thoroughly and cleaning a place makes the workplace pleasant.

Ø Personal

hygiene is essential for healthy workforce.

The Fifth

S : SHITSUKI : DISCIPLINE

Discipline especially with regard to safety rules

and punctuality.

Consequences

of not practicing SEIKETSU

Ø If

discipline is not practiced, then the first 4-S would backslide.

Ø Lack of

Shitsuki means not following the standards. Then, all activities related to

safety and quality will be affected.

IMPLEMENTING

5-S

1.

Top Management resolve and training.

2.

Formation of a top level team.

3.

Understanding current circumstances.

4.

Establishing priorities and targets.

5.

Forming sub-teams and training.

6.

Major cleaning.

7.

Establishing improvement plans in each priority

area.

8.

Implementing the plan.

9.

Verifying results.

10. Standardizing.

11. Establishing

full control.

12. Looking

for further improvements.

KAIZEN

Kaizen is a Japanese word for the philosophy that

defines management’s roles in continuously encouraging and implementing

small improvements involving everyone.

It focuses on simplification by

breaking down complex progress into their sub –

processes and then improving them.

KAIZEN

WHEEL

The

Kaizen improvement focuses on the use of :

Ø Value – added

and non – value

work activities.

Ø Muda,

which refers to the seven classes of waste –

over-production, delay, transportation, processing, inventory, wasted motion,

and defective parts.

Ø Principles

of motion study and the use of cell technology.

Ø Principles

of materials handling and use of one – piece

flow.

Ø Documentation

of standard operating procedures.

Ø The

five S’s for workplace organization.

Ø Visual

management.

Ø Just – in – time

principles.

Ø Poka – Yoke.

Ø Team

dynamics.

Related Topics