Chapter: Aquaculture Engineering : Sea Cages

Design of the mooring system

Design of the mooring system

The design used

for the mooring system depends on the type of cages to be moored: these may be

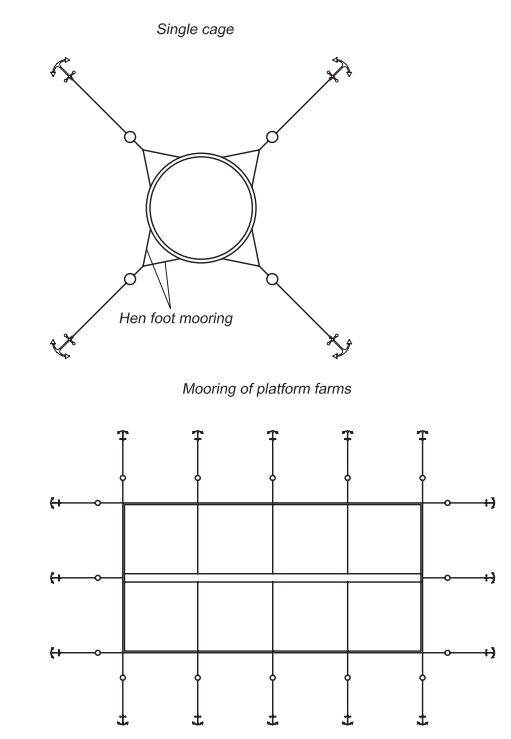

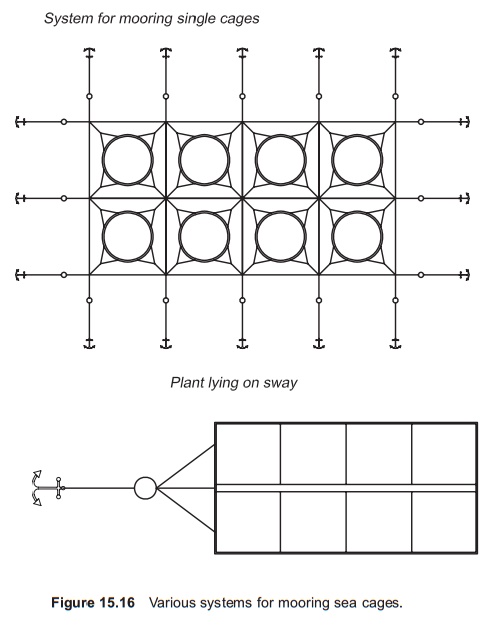

as follows (Fig. 15.16):

· Single cages

· System for

mooring several single cages

· Single cages

with walkway

· Single cages

with walkway and landing

· Group of cages – platform cages

· Ocean cages

· Cages lying on sway.

A single cage

may be moored by between four and six single buoys attached to anchors and to

the cage by mooring lines. It is recommended that the single mooring line be

divided into two before the fixing point to the cage; this is known as the hen

foot mooring; it reduces the forces at the points of attachment to the cage

framework, because the number of fixing points is doubled. The points of

attachment are critical in the mooring system, because all forces are

transferred through these points. The cost of mooring single cages is high; the

system is most viable for circular and polygonal cages.

Today, systems

for mooring several cages are more usually used. Two or three longitudinal

mooring lines are attached to each other with trans-verse mooring lines; in

this way a frame where the single cages can be fixed is built. By lowering the

frame 1–2 m below the water surface, access to the cages by boat is improved.

Here again, the single cages are attached to the frame with a hen foot mooring.

One single cage may be removed, taken out from the system and transferred to

another site.

Single cages

may also be moored to walkways. If the walkway has a landing, the requirement

to keep the cages in the same position is greater (high position exactness);

the pre-stress in the mooring lines must also be higher. With such moorings the

problem is that the wave is transmitted through the cage and the walkway with

different velocities, resulting in large forces at the connection points. The

connection point may therefore be subject to material failure. To reduce the

forces it is advanta-geous to use several connection points. Alterna-tively,

the connection point must be flexible. Fixed connections to walkways are not

recommended in exposed water.

In ocean cages

the requirements for the moorings system are large because the forces are so

great. Ocean cages are moored individually and the producer will normally have

their own mooring systems, which could be an integral part of the cage

construction.

In a platform

cage farm the mooring line is typically withdrawn from each corner and from the

middle of the farm. Such farms are normally sited in protected water because

they tolerate lower waves, due to their construction with linkages.

If the sway

principle is used, only one mooring point is necessary; it is actually a slack

mooring. This mooring point is exposed to large forces and a big anchor and

buoy are necessary. Such farms need a large area because the unit will drift

around the mooring point. Ageing of the sites is, however, delayed when using

this arrangement. However, the method is seldom used, mainly because such a

large area is necessary.

Related Topics