Chapter: Aquaculture Engineering : Sea Cages

Construction of sea cages

Construction of sea cages

A typical sea cage comprises several parts: the cage collar or support system (framework), the flotation system, the net bag, a jumping net, and weights to stretch out the net bag at the bottom and to stabilize it in the water column.

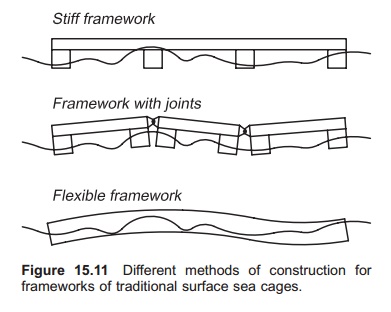

Three different methods may be used to construct the framework/collar for a sea cage (Fig. 15.11).

· Stiff framework The framework does not followthe wave movements. An example of a stiff construction is a boat. Some specially designed steel cages use a stiff framework. The construc-tion is characterized by large forces transferred to the framwork.

· Framework with movable joints The frameworkwill to some extent follow the wave move-ments. An example is a traditional steel cage system, where joints are used to connect the single elements in the framework.

· Flexible framework The framework is quiteflexible and will follow the wave movements well. These include frames made of plastic (for example, polyethylene, PE) which are flexible to some degree and those made of rubber (for example, ocean cages).

Cage collar or framework

The collar or framework may have several functions. It helps to support the cage safely in the water column, it helps to maintain the shape of the net bag, it may help with buoyancy and it may serve as a work platform.

The framework construction for stretching out the net bag can be combined with the buoyancy, as seen in plastic floating ring cages (PE or polypropylene (PP) pipes). Alternatively, the buoyancy can be independent of the cage collar as can be seen when using wood or steel for support systems with blocks of expanded polystyrene (PS), such as StyrofoamTM, as buoyancy.

The buoyancy is necessary to keep the cage bag in the correct position in the water column. It must have a smooth surface to inhibit the accumulation of fouling. Fouling increases the weight of the collar, which results in increased requirements for buoyancy; furthermore, fouling will increase the friction between the flowing water and the sea cages which again increases the forces on the mooring system. Expanded polystyrene is commonly used as buoyancy; if not covered with PE, exposure to sunlight causes it to age. It turns yellow and becomes brittle. Uncovered polystyrene will also be very prone to fouling, because the surface becomes so rough. The use of uncovered poly-styrene in sunlight is not recommended; to increase its durability it is quite common to put it into PE cylinders or rhombs.

If too much buoyancy is added the cage collar will float high up in the water column and fully follow the wave motions, floating on top of the water column throughout. Unnecessarily large forces on the cage bag and mooring system from the induced vertical motion result if there is much wave action in the area. The cost of the buoyancy will also be unnecessarily high. Buoyancy elements ought to have an aerodynamic shape to reduce the forces transferred from the water current. The current forces on the collar are, however, much smaller than the forces on the net bag.

The framework or collar can be of circular, polyg-onal or square construction. It is best to use a round framework because the forces are equal all around the circumference; polygonal or square frameworks will have large forces in the corners and eventually breakages in the construction will occur here (see, for example, ref. 15). For this reason, good connections at these points are important. Wooden frame-works are sometimes used to construct sea cages; only bolts, nails or ropes are used to connect the planks at the corners. If these cages are used in exposed sites with fast currents and high waves, the framework will break at the weak points in the corners.

Polygonal collars are better than square collars because there are more corners to share the total forces, and the force in each corner is therefore reduced.

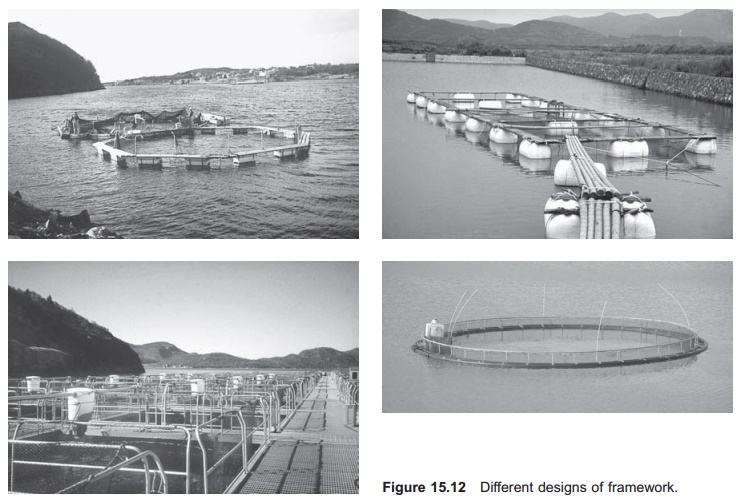

Different materials may be used in the frame-work (Fig. 15.12), ranging from steel, aluminum, wood and concrete which are rigid, to more flexible materials such as PE and rubber. The modulus of elasticity for the material is a measure of its rigid-ity and is given by its E value, the load in relation to non-permanent deformation. Steel has a high E value, while wood has a rather lower value;1 that for PE is even lower. Bamboo is also used in cage collars, but only on low exposed sites.

The risk of corrosion of the framework in sea-water when using steel or aluminum must be taken

Weighting and stretching

Weights on the bottom of the net bag are used to keep the net bag down, and to maintain as much effective volume as possible for the fish. Lead rope may be used for the bottom line in the net bag together with lump weights. The lump weights are normally added at the corners and in the centre. For example, on a 15 m × 15 m square cage, the total amount of weights can be 150–200 kg, divided into lump weights of 25 kg in each corner and in the centre, and the rest evenly spread along the bottom line as lead rope.

Rapid currents will decrease the effective volume and adding more lump weights can inhibit this; however, care must be taken because this will increase the current forces on the net bag. The need for buoyancy will also increase, and the same will be the case for the size of the mooring system. Use of weights will also increase the dynamic forces on the net bag caused by the waves (stretch and slack).

Instead of using weights, stays may be used to stretch out the net bag; this gives a rigid construction. The environmental forces will be greatly increased by doing this and the bag will require a much larger mooring system.

Net bags

Net bags can be constructed in different ways and with different materials.16–18In the past materials such as cotton and flax were used. These materials get heavy in water and their strength is rapidly reduced; in addition they are not very durable. Today synthetic plastic materials, such as polyamide (PA; nylon) predominate. This material is cheap, strong and not too stiff to work with. PE is also used to some extent because it is more resistant to fouling as the surface is smoother; it is however, stiffer to work with. Polyester (PES) has also been tried.

Nylon used for nets is made as a multifilament consisting of several thin threads spun together to make a thicker one. The advantage with multifilament is that the thread is easy to bend, easy to work with, tolerates more loads and is more resistant to chafing. In contrast, monofilament is a single thread as used in a fishing line. It can be made of PE; it is stiffer and more vulnerable to chafing than a multifilament.

Nets are either knotted or knotless, in which case they are sewn together. In the past there were problems with knotless nets because they came unstitched, but today this problem has been over-come and both knotted and knotless nets are in common use.

The normal mesh shape is square; hexagonal meshes are also used, but to a lesser extent. Hexagonal meshes are more commonly used for trawling bags on fishing vessels.

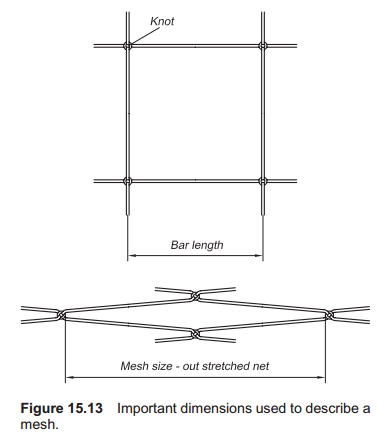

A number of dimensions are used to describe the mesh. Bar length is the distance between two knots while mesh size is the distance between the knots on a stretched mesh. Mesh size may, however, also refer to bar length, which makes this expression rather confusing. In a hexagonal mesh, the mesh size is given as the distance between the two longest parallel bars (Fig. 15.13).

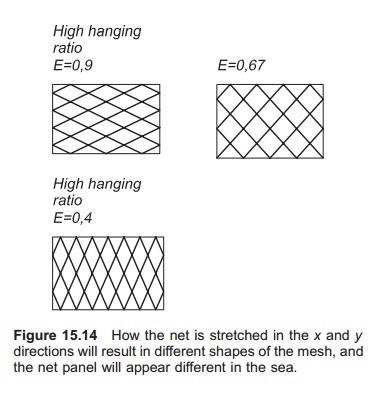

Another expression that indicates how the net panel is standing in the sea is how the net is stretched in the x and y directions. This can be called the hanging ratio of the net (E). This is the ratio between the length of the stretched net panel (Ly) and the length of the line where the net is fixed (top line) (Lx):

E = LX/Ly

Normally E for net bags for fish farming is in the range 0.6–0.9, while for a fishing net, for instance, E is between 0.4 and 0.6, meaning that fishingnets have meshes that are more stretched out (Fig. 15.14).

Solidity is used to describe how ‘tight’ a net is and is the ratio between the total area that the net covers, compared to the area covered with threads including knots. This relation is important when the resistance against water flow through the net is to

The material strength of net panels exposed to sunlight (UV), wind, rain, acid rain, etc. is reduced. This process is called weathering. Polyvinyl chloride (PVC) is the material that is most resistant to ageing, followed by PE and PA; PP has the shortest lifetime. The lifetime can be increased by adding a coloured (black) antioxidant, so the development of weathering is reduced. Today, however, white untreated material is commonly used for net bags. As it is usual to add some type of antifouling agent to the nets, this will also cover the multifilament.

The normal lifetime of a net bag will vary with the site conditions; in Norway, for example, the life-time of a net bag is usually set as 5 years.19Another way of controlling the duration of a net bag is to carry out a strength test. In Norway, the breaking strength of the net bag below the surface must not fall below 65% of the initial strength.

When the bag is exposed to water currents the volume is reduced by deflection. Because of this, the net bag must be correctly constructed. Narrow deep nets are not recommended on sites exposed to cur-rents. Recommended net depths are 0.8–1.25 times the diameter of the bag.

Because wave motions decrease significantly with increasing depth, it is an advantage to place the cage bags at some depth on exposed sites; 15–25 m deep is normal for large cages with a circumference above 60 m. The recommended depth of cage bags in some exposed sites is more than eight times the significant wave height.

The merits of vertical or sloping sides in the net bag are as follows. Volume reduction is limited by using sloping sides, but if the amount of lump weights has to be increased to maintain bag volume, the forces are reduced if the bag has vertical sides.

Breakwaters

On sites exposed to waves, breakwaters may be used to reduce wave height and impact. Hence the environmental loads on the cages lying behind the breakwater will also be reduced. Breakwaters may be constructed in different ways.1 One method is to use concrete blocks or a steel construction fixed to the bottom; however, these are expensive to install and little used for protection of sea cages in deep water, although they may be used in shallow water. Pneumatic barriers with air bubbles may also occasionally be used. Most usually a breakwater made of rubber tyres is used. Old tyres from trucks or cars are tied up with wire to form a fleet. The width of the breakwater is important for its effect on the breaking waves. It is normal to use several break-waters and their total width must be at least as great as the width of the farm to be protected. The width of a breakwater is recommended to be at least 1.5 times its length.21This is because the most damaging wavelengths are 0.5–1.25 times the length of the structure. A simple pipe will to some extent function as a breakwater, but it is much less effective than specially designed breakwaters; eventually several pipes can be placed adjacent to each other.

Breakwaters can be moored like sea cages. Some distance is necessary between the breakwater and the farm: up to four wavelengths is recommended.1The breakwaters will then create a shadow where the cages are placed.

The breakwater decreases the wave height by reducing the energy in the wave. This is because there is:

· Reflection and waves travelling in the opposite direction are created

· Distribution in the breakwater

· Transfer of energy to the breakwater

· Deflection of waves hitting the corners of the breakwater.

Related Topics