Chapter: 11th 12th std standard Home Science Maintain Basic Knowledge for family life Higher secondary school College

Buttons and Buttonholes

Buttons and Buttonholes

Button

closings should be appropriate to the style of the garment. Buttons too large,

or too small, or of the wrong texture can mar the entire design. There are also

decorative buttons which should be selected with same care as costume

jewellery.

To Determine the

length of buttonhole

The length of the buttonhole is determined by

the particular button size you use. The general rule is the diameter plus

height of button equals length of buttonhole.

A slash can be made by cutting scrap of fabric

and the button to be stitched can be passed through it. But the general rule is

an excellent guide to follow.

Placement of Fabrics

Buttonholes are placed on the right so that right overlaps left while

securing the buttons for girls and women garments and buttonholes are put in

the left front for men garments to facilitate left over right closing.

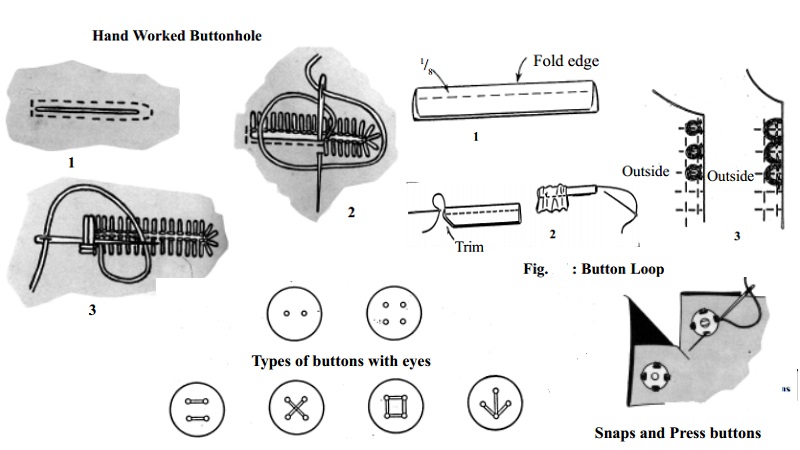

Hand Worked

Buttonholes

The following are the steps to work buttonholes by hand.

1.

Work a basting stitch through the buttonhole

marking near the center-front line. Decide on the length of buttonhole and put

in a marking basting parallel to the first. Mark placement of buttonholes with

a cross basting.

2.

Machine stitch around the rectangle. Count the

stitches, so that the rectangles will be equal in length and width, double

stitch for a few stitches so that no knot will be needed. Remove bastings. Cut

down the center of each rectangle, cutting exactly along a thread of the

fabric.

Work

buttonhole stitches from right to left. Put the needle through the slashed

opening with the point of the needle coming through the fabric just beyond the

machine stitches. Bring both the threads around the point of the needle and

complete the stitch, keeping the loops of thread along the cut edge of the

slash. Repeat the stitch and be sure the stitches are close together, revealing

no fabric between them. They must also be of an equal depth.

Worked buttonholes have a fan shape at the end nearest to the center

front, where there will be strain due to the pull on the button. The other end

is called the bar end. Make several long stitches at the end to form the bar.

Button loops

Button loops are made on cuffs of sleeves, as well as at the front or

back of blouses and dresses. Button loops can often be substituted for

buttonholes, provided loops are compatible with the overall style of the

garment. Although any type of buttons can be used in loops, ball buttons fit

will be best. Button loops may be set into the seam at the opening edge of the

garment, or they may be part of an intricate, decorative shape called a frog,

which is served in place on the outside of the finished garment.

Always make a test loop to see how the fabric works

into tubing, and to determine the proper size for the loop. Sew a button onto a

scrap of fabric to be sure that the loop will slip easily but also fit snugly

over the button, which it must, if it is to hold the garment edges securely

closed. Also check the diameter of the tubing to see whether it is suitable to

the button size.

Making loop or Tubing

Cut true bias strips of fabric 2½ inches long and 1 inch inside. Fold

inhalf lengthwise with right sides together. Stitch about 1/8

inch from folded edge, stretching the fabric slightly and being careful to keep

the line of stitching parallel to the edge. Thread a large needle with several

inches of heavy-duty thread. Fasten thread at seam at one end of tubing, then

insert needle, eye first, into tube and work it through to other end. Gradually

turn all the tubing to the right side. This can be done by pulling on thread

and feeding seam allowance into tube.

Attaching the loops to

the garment

1.

Stitch as many number of loops required

according to the number of buttons. Buttons should be placed on the right front

and close together with no more than ¼ inch between them. Run a marking basting

stitch along the seam line at the front edge. Use cross basting to mark the

spacing for the loops.

2.

Experiment with the size of loop needed for the

button. Tack one tube into a loop and push the button through it; it should be

a snug fit but not so snug as to cause undue strain on the button or the loop.

When the size is correct, put another row of marking basting the required

distance from the seam line.

3.

The loops may be attached in one of two ways as

shown. The finished appearance is slightly different. They must be basted to

the seam line with very firm, small stitches, and trim off excess length of

loops.

Button placement

Button position should be marked when the garment is nearly completed

and after the buttonholes or button loops are made. Although button position

line should be marked at the beginning of construction and button location can

be marked, the location should be finally determined when buttonholes are

finished. Lap buttonhole side of garment over button side as garment will be

worn, matching center front or center back lines, pin securely between

buttonholes.

For horizontal buttonholes, place a pin through buttonhole opening, 1/8

inch from the end that is nearest the finished garment edge, into fabric

beneath. For vertical buttonholes, button should be positioned 1/8

inch below the top of the buttonhole opening. Carefully lift the buttonhole

over pin and refasten the pin securely at the proper location. Center button at

pin mark, directly on centerline, and sew in place according to the type of

button you are using.

To sew a button with eyes

Buttons for tailored garments may have either two or four eyes. The

button with four eyes can become a subtle design feature, for the thread can be

inserted through the eyes in various ways.

This button is flat with no shank, and so one must be made with thread.

This is done by sewing over a match to make the stitches looser than they

otherwise would be. From the outside take a small stitch (1/ 16

inch) at the desired point; catching through all thicknessess. Take another

thread to secure the knot. Place the match over the button and bring the needle

up through the eyes of the button. Take several stitches through the button and

over the match. Remove the match and lift the button to pull the threads tight

against the button, a shank of threads will appear beneath the button. Wind the

thread around and around these threads, and fasten thread securely .

Snaps and Press buttons

Snaps are a kind of small fastener, have less holding power than hooks

and eyes. Each snap has two parts - a ball half and a socket half. Snaps are

available in various sizes and weights to serve every purpose. They are either

black or silver.

1.

Mark position of snaps; if a row of them is

required, space them evenly.

2.

Place the flat surface on the edge of the garment

that will be upper most when finished.

3.

Use a double thread of matching colour.

4.

Take several small overhand stitches through one

hole, slip the needle under the snap, and bring it out alongside the next hole.

5.

Take small overhand stitches through that hole

and continue.

6.

Stitches should not be seen on the right side of

the garment. Fasten threads.

Related Topics