Chapter: Mechanical and Electrical : Power Plant Engineering : Coal Based Thermal Power Plants

Types of pulverised coal firing system

Types of pulverised coal firing

system

(i) Unit system (or) Direct System

(ii) Bin (or) Central system

(iii)Semi direct firing system.

Pulverised Coal Firing System:

Pulverised coal firing is done by two

systems:

i)

Unit

system or Direct System.

ii)

Bin

or Central system

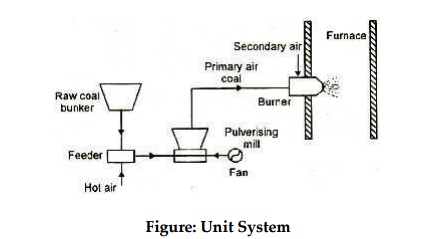

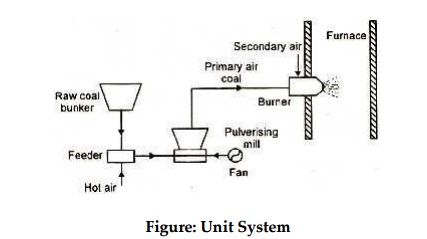

Unit System:

In this system, the raw coal from the

coal bunker drops on to the feeder.

Hot air

is passed through coal in the factor to dry the coal. The coal is then

transferred to the pulverising mill where it is pulverised. Primary air is

supplied to the mill, by the fan. The mixture of pulverised coal and primary

air then flows to burner where secondary air is added. The unit system is so

called from the fact that each burner or a burner group and pulverizer

constitute a unit.

Advantages:

1. The system is simple and cheaper than

the central system

2. There is direct control of combustion

from the pulverising mill.

3. Coal transportation system is simple.

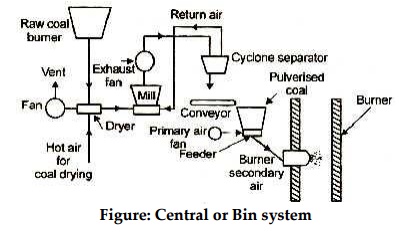

Central

or Bin System

It is

shown in figure. Crushed coal from the raw coal bunker is fed by gravity to a

dryer where hot air is passed through the coal to dry it. The dryer may use

waste flue gasses, preheated air or bleeder steam as drying agent. The dry coal

is then transferred to the pulverising mill. The pulverised coal obtained is

transferred to the pulverised coal bunker (bin). The transporting air is

separated from the coal in the cyclone separator. The primary air is mixed with

the coal at the feeder and the mixture is supplied to the burner.

Figure: Central or Bin system

Advantages

1.

The

pulverising mill grinds the coal at a steady rate irrespective of boiler feed.

2.

There

is always some coal in reserve. Thus any occasional breakdown in the coal

supply will not affect the coal feed to the burner.

3.

For

a given boiler capacity pulverising mill of small capacity will be required as

compared to unit system.

Disadvantages

1.

The

initial cost of the system is high

2.

Coal

transport system is quite complicated

3.

The

system requires more space.

Semidirect

Firing System:

A cyclone separator between the pulverizer and furnace

separates the conveying medium from the coal. The hot primary air separated in

the cyclone is used by the exhauster or primary air fan to push the coal

particles, falling by gravity from the cyclone, through the burners into the furnace.

Related Topics