Chapter: Mechanical and Electrical : Power Plant Engineering : Coal Based Thermal Power Plants

Process of the Rankine Cycle

Type of Basic Boilers thermodynamic

cycles process of the Rankine cycle

BOILER

CYCLES

In general, two important area of

application for thermodynamics are:

1. Power generation

2. Refregeration

Both are

accomplished by systems that operate in thermodynamic cycles such as:

a.

Power

cycles: Systems used to produce net power output and are often called engines.

Refrigeration

cycles: Systems used to produce refregeration effects are called refregerators

2. Vapour power cycles

In

this case, the working fluid exists in the vapour phase during one part of the

cycle and in the liquid phase during another part.

Vapour power cycles can be

categorized as

a.

Carnot

cycle

b.

Rankine

cycle

c.

Reheat

cycle

d.

Regenerative

cycle

e.

Binary

vapour cycle

Steam cycles (Ranking cycle)

The

Rankine cycle is a thermodynamic cycle. Like other thermodynamic cycle,

the maximum efficiency of the Ranking cycle is given by calculating the maximum

efficiency of the carnot cycle.

Process of the Rankine Cycle

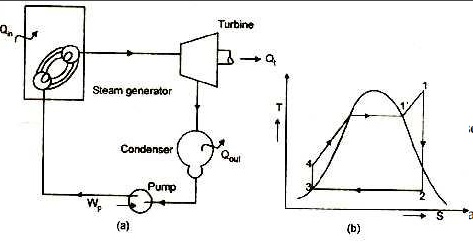

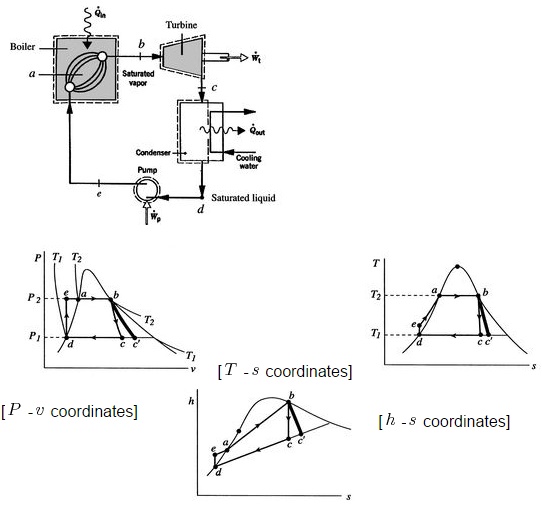

Figure:

Schematic rep

There are

four processes in the Rankine cycle, each changing the state of the working

fluid. These states are identified by number in the diagram above.

Process

3-4:

First, the working fluid (water) is enter the pump at

state 3 at saturated liquid and it is pumped (ideally isentropically) from low

pressure to high (operating) pressure of boiler by a pump to the state 4.

During this isentropic compression water temperature is slightly increased.

Pumping requires a power input (for example, mechanical or electrical). The

conservation of energy relation for pump is given as

Wpump = m (h4 - h3)

Process

4-1:

The high pressure compressed liquid enters a boiler at

state 4 where it is heated at constant pressure by an external heat source to

become a saturated vapour at statel’which in turn superheated to state 1

through super heater. Common heat source for power plant systems are coal (or

other chemical energy), natural gas, or nuclear power. The conservation of

energy relation for boiler is given as

Qin =m (h1 - h4)

Process

1 –2:

The superheated vapour enter the turbine at state 1 and

expands through a turbine to generate power output. Ideally, this expansion is

isentropic. This decreases the temperature and

pressure

of the vapour at state 2. The conservation of energy relation for turbine is

given as

Wturbine = m (h1 –h2)

Process

2 –3:

The vapour then enters a condenser at state 2. At this

state, steam is a saturated liquid-vapour mixture where it is cooled to become

a saturated liquid at state 3. This liquid then re-enters the pump and the

cycle is repeated. The conservation of energy relation for condenser is given

as

Qout = m (h2 –h3)

The exposed Rankine cycle can also prevent vapour

overheating, which reduces the amount of liquid condensed after the expansion

in the turbine.

Description

Rankine

cycles describe the operation of steam heat engines commonly found in power

generation plants. In such vapour power plants, power is generated by

alternatively vaporizing ng fluid (in many cases water, although refrigerants

such as ammonia in a Rankine cycle follows a closed loop and is re-used

constantly. Water vapour seen billowing from power plants is evaporating

cooling water, not working fluid. (NB: steam is invisible until it comes in

contact with cool, saturated air, at which point it condenses and forms the

white billowy clouds seen leaving cooling towers).

Variables

Qin- heat

input rate (energy per unit time) m= mass flow rate (mass per unit time)

W- Mechanical power used by or

provided to the system (energy per unit time)

h-

thermodynamic efficiency of the process (power used for turbine per heat input,

unit

less).

The thermodynamic efficiency of the

cycle as the ratio of net power output to heat input.

Wnet =(Wturbine -Wpump )or (Qin

-Qout )

h=Wnet / Qin

Real Rankine Cycle variation of Basic

Rankine Cycle

Real Ranking Cycle (Non-ideal)

Figure:

In

a real Rankine cycle, the compression by the pump and the expansion in the

turbine are not isentropic. In other words, these processes are non-reversible

and entropy is increased during the two process (indicated in the figure). This

somewhat increases the power required by the pump and decreases the power

generated by the turbine. It also makes calculations more involved and

difficult.

Variation of the Basic Rankine Cycle:

Two main

variations of the basic Rankine cycle to improve the efficiency of the steam

cycles are done by incorporating Reheater and Regenerator in the ideal ranking

cycle.

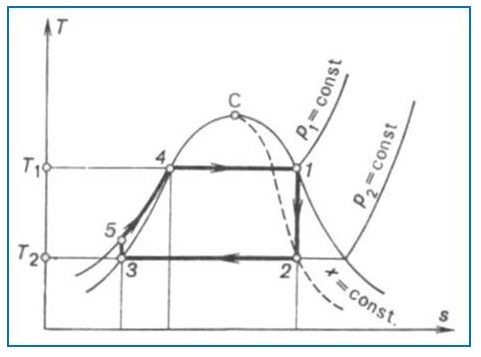

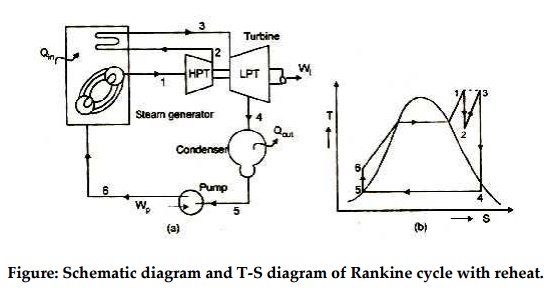

Rankine

cycle with reheat

Figure: Schematic diagram and T-S

diagram of Rankine cycle with reheat.

In this variation, two turbines work in series. The first

accepts vapour from the boiler at high pressure. After the vapour has passed

through the first turbine, it re-enters the boiler and is reheated before

passing through a second, lower pressure turbine. Among other advantages, this

prevents the vapour from condensing during its expansion which can seriously

damage the turbine blades.

Related Topics