Chapter: Mechanical and Electrical : Power Plant Engineering : Coal Based Thermal Power Plants

Classification of Ash Handling System

Classification

of Ash Handling System

i) Hydraulic system

ii) Pneumatic system

iii) Mechanical system

The commonly used ash discharge

equipment is as follows:

i) Rail

road cars ii) Motor truck iii) barge

Hydraulic System

In

this system, ash from the furnace grate falls into a system of water possessing

high velocity and is carried to the sumps. It is generally used in large power

plants. Hydraulic system is of two types, namely, low pressure hydraulic system

used for intermittent ash disposal figure. Figure shows hydraulic system.

Figure:

Hydraulic system

In this method water at sufficient pressure is used to

take away the ash to sump. Where water and ash are separated. The ash is then

transferred to the dump site in wagons, rail cars to trucks. The loading of ash

may be through a belt conveyor, grab buckets. If there is an ash basement with

ash hopper the ash can fall, directly in ash car or conveying system.

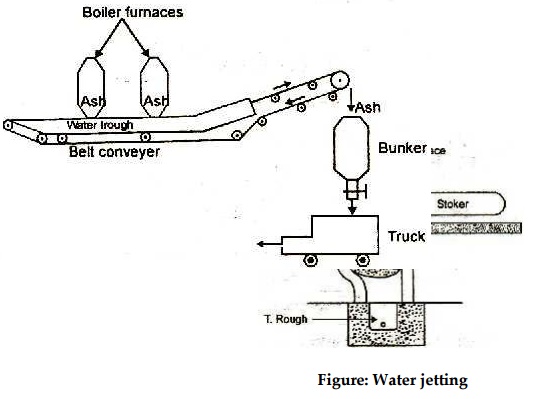

Water jetting of ash is shown in figure. In this method a

low pressure jet of water coming out of quenching nozzle is used to cool the

ash. The ash falls into trough and is then removed.

Pneumatic System

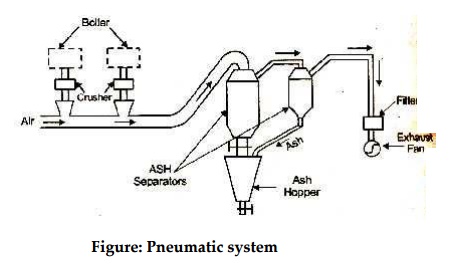

In this system ash from the boiler furnace outlet falls

into a crusher where a lager ash particles are crushed to small sizes. The ash

is then carried by a high velocity air or steam to the point of delivery. Air

leaving the ash separator is passed through filter to remove dust etc. So that

the exhauster handles clean air which will protect the blades of the exhauster.

Figure: Pneumatic system

Mechanical system

Figure: Mechanical system

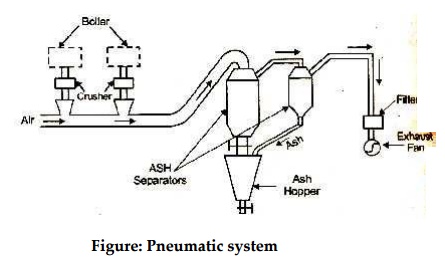

Figure shows a mechanical ash handling system. In this

system ash cooled by water seal falls on the belt conveyor and is carried out

continuously to the bunker. The ash is then removed to the dumping site from

the ash banker with the help of trucks.

Related Topics