Chapter: Mechanical and Electrical : Power Plant Engineering : Coal Based Thermal Power Plants

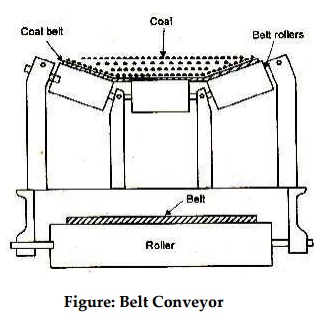

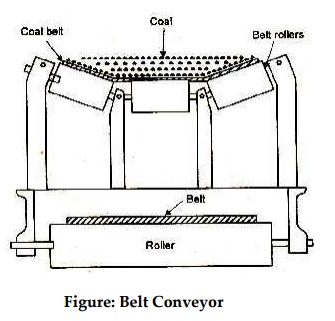

Belt Conveyor

Belt

Conveyor

Figure: Belt Conveyor

Figure

shows a belt conveyor. It consists of an endless belt moving over a pair of end

drums (rollers). At some distance a supporting roller is provided at the

centre. The belt is made up of rubber or canvas. Belt conveyor is suitable for

the transfer of coal over long distances. It is used in medium and large power

plants. The initial cost of system is not high and power consumption is also

low. The inclination at which coal can be successfully elevated by belt conveyor is about 20°. Average

speed preferred than other types.

Advantages

of belt conveyor

1.

Its

operation is smooth and clean

2.

It

requires less power as compared to other types of systems

3.

Large

quantities of coal can be discharged quickly and continuously.

4.

Material

can be transported on moderate inclines.

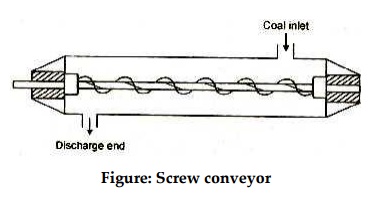

2. Screw Conveyor

It consists of an endless helicoid screw fitted to a shaft

(figure). The screw while rotating in a trough transfers the coal from feeding

end to the discharge end.

Figure: Screw conveyor

This system is suitable, where coal is to be transferred

over shorter distance and space limitations exist. The initial cost of the

consumption is high and there is considerable wear o screw. Rotation of screw

varies between 75-125 r.p.m

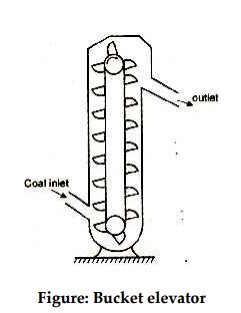

3.

Bucket elevator

It consists of buckets fixed to a chain (figure). The

chain moves over two wheels. The coal is carried by the bucket from bottom and

discharged at the top.

4.

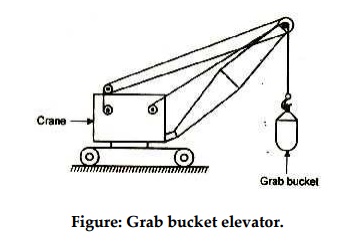

Grab bucket elevator

It lifts and transfers coal on a single rail or track from

one point to the other. The coal lifted by grab buckets is transferred to

overhead bunker or storage. This system requires less power for operation and

requires minimum maintenance.

The grab bucket conveyor can be used with crane or tower as

shown in figure . Although the initial cost of this system is high but

operating cost is less.

Figure: Grab bucket elevator.

Storage

of Coal

It is desirable that sufficient quantity of coal should be

stored. Storage of coal gives protection against the interruption of coal

supplies when there is delay in transportation of coal or due to strike in coal

mines. Also when the prices are low, the coal can be purchased and stored for

future use. The amount of coal to be stored depends on the availability of

space for storage, transportation facilities, the amount of coal that will

whether away and nearness to coal mines of the power station. Usually coal

required for one month operation of power plant is stored in case of power

stations are situated at longer distance from the collieries whereas coal need

for about 15 days is stored in case of power station situated near to

collieries. Storage of coal for longer periods is not advantageous because it

blocks the capital and results in deterioration of the quality of coal.

Related Topics