Chapter: Mechanical and Electrical : Power Plant Engineering : Coal Based Thermal Power Plants

Pulverized coal storage in Bunker and coal handing system

Pulverized

coal storage in Bunker

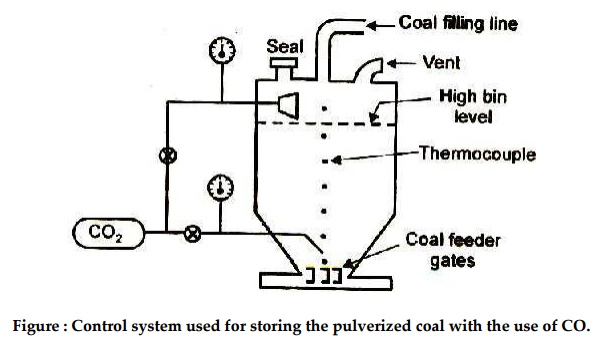

Periodically a power plant may encounter the situation

where coal must be stored for sometimes in a bunker, for instance during a

plant shut down. The bunker, fires can occur in dormant pulverized coal from

spontaneous heating within 6 day of loading. This time can be extended to 13

days when a blanket of CO2 is piped into the top of the bunker. The perfect

sealing of the bunker from air leakage can extend the storage time as two months

or more. The coal in the bunker can be stored as long as six months by

expelling air from above the coal with the use of CO2 and then blanketing of

all sources of air. A control system used for storing the pulverized fuel in

bunker is shown in figure.

Figure : Control system used for

storing the pulverized coal with the use of CO.

pulverized

coal handing system and Pulverized Fuel

Handling

System:

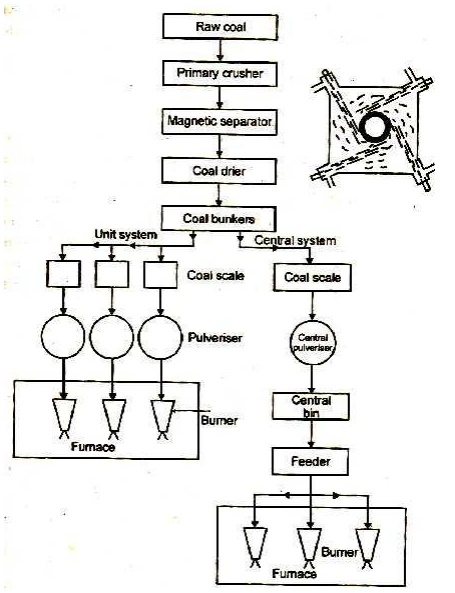

Two methods are in general use to feed the pulverized fuel

to the combustion chamber of the power plant. First is ‘Unit System’ secoand is

‘Centralor Bin System ‘.

In unit system, each burner of the plant is fired by one

or more pulverizers connected to the burners, while in the central system, the

fuel is pulverized in the central plant and then disturbed to each furnace with

the help of high pressure air current. Each type of fuel handling system

consists of crushers, magnetic separators, driers, pulverizing mills, storage

bins, conveyors and feeders.

Figure: Pulverized coal handling plant showing all

required equipment for unit and central system.

The arrangement of different equipment required in both

systems is shown in figure. With the help of a block diagram.

The coal received by the plant from the mine may vary

widely in sizes. It is necessary to make the coal of uniform size before

passing the pulverizer for efficient grinding. The coal received from the mine

is passed through a preliminary crusher to reduce the size to allowable limit

(30 mm). The crushed coal is further passed over magnetic separator which

removes pyrites and tramp iron. The further equipment through which coal is

passed before passing to pulverizer are already shown in figure.

a) Ball mill pulverizing

Ball and Race mill pulverizing

a)

Ball Mill

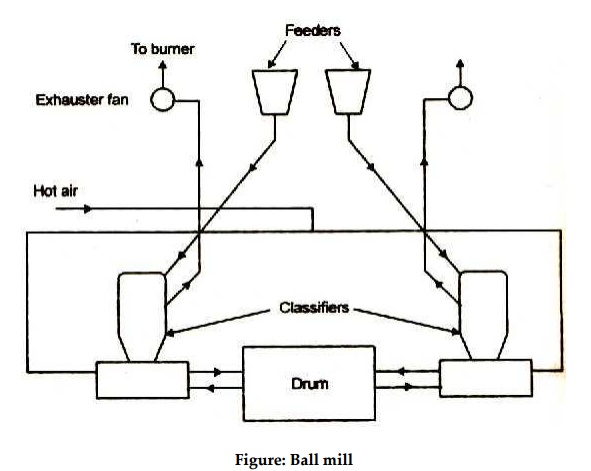

A line diagram of ball mill using two classifiers is shown

in figure. It consists of a slowly rotating drum which is partly filled with

steel balls. Raw coal from feeders is supplied to the classifiers from where it

moves to the drum by means of a screw conveyor. As the drum rotates the coal

get pulverized due to the combine impact between coal and steel balls. Hot air

is introduced into the drum. The powdered coal is picked up by the air and the

coal air mixture enters the classifiers, where sharp changes in the direction

of the mixture throw out the oversized coal particles. The over-sized particles

are returned to the drum. The coal air mixture from the classifier moves to the

exhauster fan and then it is supplied to the burners.

Ball

and Race Mills

Figure: shows a ball and race mill

In this mill the coal passes between the rotating elements

again and again until it has been pulverized to desired degree of fineness. The

coal is crushed between two moving surfaces, namely, balls and races. The upper

stationary race and lower rotating race driven by a worm and gear hold the

balls between them. The raw coal supplied falls on the inner side of the races.

The moving balls and races catch coal between them to crush it to a powder. The

necessary force needed for crushing is applied with the help of springs. The

hot air supplied picks up the coal dust as it flows between the balls and races

and then enters the classifier. Where oversized coal particles are returned for

further grinding. Where as the coal particles of required size are discharged

from the top of classifier.

Advantages:

i) Lower capital cost

ii) Lower power consumption

iii)

Less

space required.

iv) Less weight

Related Topics