Chapter: Mechanical and Electrical : Power Plant Engineering : Coal Based Thermal Power Plants

Natural Draught

Natural

Draught with advantages and disadvantages applications in Natural Draught:

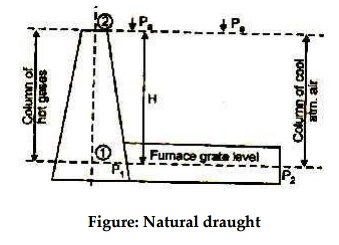

Natural draught system employs a tall chimney as shown in

figure. The chimney is a vertical tubular masonry structure or reinforced

concrete. It is constructed for enclosing a column

of exhaust gases to produce the draught. It discharges the

gases high enough to prevent air pollution. The draught is produced by this

tall chimney due to temperature difference of hot gases in the chimney and cold

external air outside the chimney.

Where H-

Height of the Chimney (m)

pa –Atmospheric pressure (N/m2)

p1 –Pressure acting on the grate from

chimney side (N/m2)

p2 –Pressure acting on the grate from

atmospheric (N/m2)

Due to this pressure difference (p), the atmospheric air

flows through the furnace grate and the flue gases flow through the chimney.

The pressure difference can be increased by increasing the height of the

chimney or reducing the density of hot gases.

Merits

of Natural Draught

1.

No

external power is required for creating the draught.

2.

Air

pollution is prevented since the flue gases are discharged at a higher level

3.

Maintenance

cost is practically nil since there are no mechanical parts.

4.

It

has longer life.

5.

Capital

cost is less than that of an artificial draught

Demerits

of natural draught

1.

Maximum

pressure available for producing draught by the chimney is less.

2.

Flue

gases have to be discharged at high temperature since draught increases with

the increase in temperature of flue gases.

3.

Heat

cannot be extracted from the flue gases for economizer, superheater, air

pre-heater, etc. since the effective draught will be reduced if the temperature

of the flue gases is decreased.

4.

Overall

efficiency of the plant is decreased since the fluid gases are discharged at

higher temperatures.

5.

Poor

combustion and specific fuel consumption is increased since the low velocity of

air affects thorough mixing of air and fuel.

6.

Not

flexible under peak loads since the draught available for a particular height

of a chimney is constant.

7.

A

considerable amount of heat released by the fuel (about 20%) is lost due to

flue gases.

Applications

Natural draught system is used only in small capacity

boilers and it is not used in high capacity thermal plants.

Related Topics