Chapter: Mechanical and Electrical : Power Plant Engineering : Coal Based Thermal Power Plants

Principles of Fluidized Bed Combustion Operation

The

working principle of

(a) Fluidized Bed Combustion

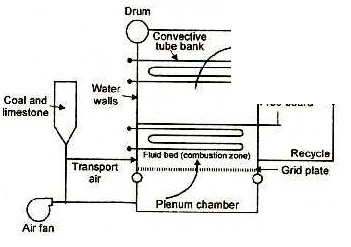

(b)Atmospheric bubbling bed combustor

(c) Circulating bed combustor

And

write the advantages of fluidized bed combustion:

Principles

of Fluidized Bed Combustion Operation:

A fluidized bed is composed of fuel (coal, coke, biomass,

etc.,) and bed material (ash, sand, and/or sorbent) contained within an

atmospheric or pressurized vessel. The bed becomes

fluidized

when air or other gas flows upward at a velocity sufficient to expand the bed.

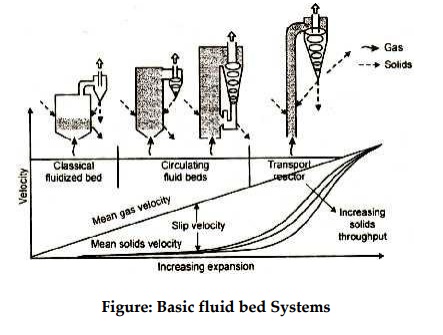

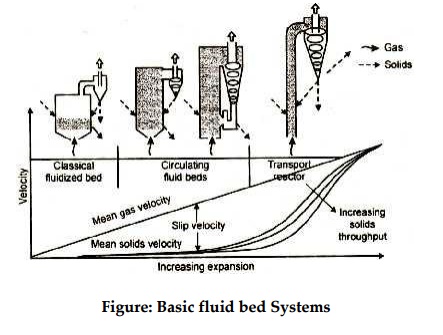

The process is illustrated in figure. At low fluidizing velocities (0.9 to 3

m/s). relatively high solids densities are maintained in the bed and only a

small fraction of the solids are entrained from the bed. A fluidized bed that

is operated in this velocity range is refered to as a bubbling fluidized bed

(BFB). A schematic of a typical BFB combustor is illustrated in figure.

Figure:

Basic fluid bed Systems

ller

particles are entrained in the gas stream and ell-defined for a BFB combustor

becomes more . A fluidized bed that is operated at velocities in fluidized bed,

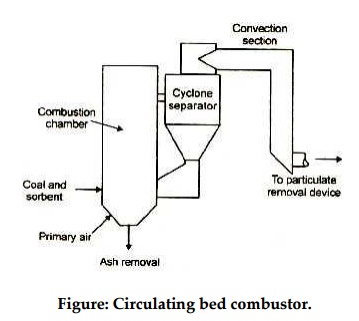

or CFB. A schematic of a typical

Figure: Circulating bed combustor.

Advantages

of fluidized bed combustion

The advantages of FBC in comparison to conventional

pulverized coal-fueled units can be summarized as follows:

1.

SO2

can be removed in the combustion process by adding limestone to the fluidized

bed, eliminating the need for an external desulfurization process.

2.

Fluidized

bed boilers are inherently fuel flexible and, with proper design provision, can

burn a variety of fuels.

3.

Combustion

FBC units takes place at temperatures below the ash fusion temperature of most

fuels. Consequently, tendencies for slagging and fouling are reduced with FBC.

4.

Because

of the reduced combustion temperature, NOx emissions are inherently low.

Related Topics