Chapter: Environmental Biotechnology: Aerobes and Effluents

Trickling Filters

Trickling Filters

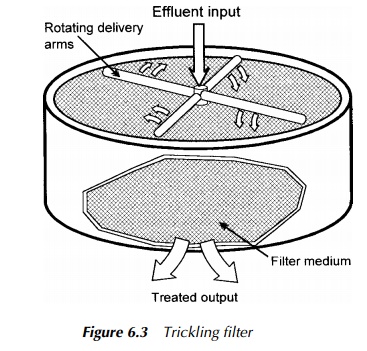

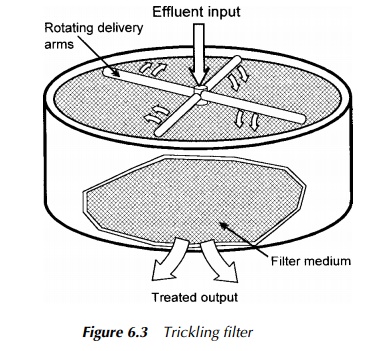

The trickling or biological filter system involves a bed, which is

formed by a layer of filter medium held within a containing tank or vessel,

often cast from concrete, and equipped with a rotating dosing device, as shown

in a stylised form in Figure 6.3.

The filter is designed to

permit good drainage and ventilation and in addition sedimentation and settling

tanks are generally associated with the system. Efflu-ent, which has been

mechanically cleaned to remove the large particles which might otherwise clog

the interparticulate spaces in the filter bed, flows, or is pumped, into the

rotating spreader, from which it is uniformly distributed across the filter

bed. This dosing process can take place either continuously or intermit-tently,

depending on the operational requirements of the treatment works. The

wastewater percolates down through the filter, picking up oxygen as it travels

over the surface of the filter medium. The aeration can take place naturally by

diffusion, or may sometimes be enhanced by the use of active ventilation fans.

The combination of the

available nutrients in the effluent and its enhanced oxygenation stimulates

microbial growth, and a gelatinous biofilm of micro-organisms forms on the

filter medium. This biological mass feeds on the organic material in the

wastewater converting it to carbon dioxide, water and microbial biomass. Though

the resident organisms are in a state of constant growth, ageing and occasional

oxygen starvation of those nearest the substrate leads to death of some of the

attached growth, which loosens and eventually sloughs, passing out of the

filter bed as a biological sludge in the water flow and thence on to the next

phase of treatment.

The filter medium itself is

of great importance to the success of these systems and in general the

requirements of a good material are that it should be durable and long lasting,

resistant to compaction or crushing in use and resistant to frost damage. A

number of substances have been used for this purpose including clinker,

blast-furnace slag, gravel and crushed rock. A wholly artificial plastic

lattice material has also been developed which has proved successful in some

applications, but a clinker and slag mix is generally said to give some of the

best results. The ideal filter bed must provide adequate depth to guarantee

effluent retention time, since this is critical in allowing it to become

sufficiently aerated and to ensure adequate contact between the microbes and

the wastewater for the desired level of pollutant removal. It should also have

a large surface area for biomass attachment, with generous void spaces between

the particles to allow the required biomass growth to take place without any

risk of this causing clogging. Finally, it should have the type of surface

which encourages splashing on dosing, to entrap air and facilitate oxygenation

of the bed.

The trickling filters in use

at sewage works are squat, typically around 8 – 10 metres across and between 1

– 2 metres deep; though these are the most familiar form, other filters of

comparatively small footprint but 5 to 20 metres in height are used to treat

certain kinds of trade effluents, particularly those of a stronger nature and

with a more heavy organic load than domestic wastewater. They are of particular

relevance in an industrial setting since they can achieve a very high

throughput and residence time, while occupying a relatively small base area of

land.

To maximise the treatment

efficiency, it is clearly essential that the trickling filter is properly sized

and matched to the required processing demands. The most important factors in

arriving at this are the quality of the effluent itself, its input temperature,

the composition of the filter medium, detail of the surface-dosing arrangements

and the aeration. The wastewater quality has an obvious signifi-cance in this

respect, since it is this, combined with the eventual clean-up level required,

which effectively defines the performance parameters of the system. Although in

an ideal world, the filter would be designed around input character, in cases where

industrial effluents are co-treated with domestic wastewater in sewage works,

it is the feed rate which is adjusted to provide a dilute liquor of given

average strength, since the filters themselves are already in existence. Hence,

in practice, the load is often adjusted to the facility, rather than the other

way about.

The input temperature has a

profound influence on the thermal relations within the filter bed, not least

because of the high specific heat capacity of water at 4200 J/kg/ ◦ C. This can

be of particular relevance in industrial reed bed systems, which are discussed

in the following, since a warm liquor can help to overcome the problems of cold

weather in temperate climes. By contrast the external air temperature appears

to have less importance in this respect. The situation within the reaction

space is somewhat complicated by virtue of the nonlinear nature of the effect

of temperature on contaminant removal. Although the speed of chemical reactions

is well known to double for every 10 ◦ C rise, at 20 ◦ C, in-filter

biodegradation only represents an increase of 38% over the rate at 10 ◦C. Below

10 ◦C, the risk of clogging rises significantly, since the activity of certain

key members of the microbial community becomes increas-ingly inhibited.

The general properties of

the filter media were discussed earlier. In respect of sizing the system, the

porosity and intergranular spaces govern the interrelation between relative

ease of oxygen ingress, wastewater percolation and nutrient to biofilm contact.

Clearly, the rougher, pitted or irregular materials tend to offer the greatest

surface area per unit volume for microbial attachment and hence, all other

things being equal, it follows that the use of such media allows the overall

filter dimensions to be smaller. In practice, however, this is seldom a major

deciding factor.

In the main, filter systems

use rotational dosing systems to ensure a uniform dispersal of the effluent,

though nozzles, sprays and mechanised carts are not unknown. The feed must be

matched to the medium if the surface aeration effect is to be optimised, but it

must also take account of the fluidity, concentration and quality of the

wastewater itself and the character of the resident biofilm.

Since the biological

breakdown of effluents within the filter is brought about by aerobic organisms,

the effectiveness of aeration is of considerable importance. Often adequate

oxygenation is brought about naturally by a combination of the surface effects

as the wastewater is delivered to the filter, diffusion from atmosphere through

the filter medium and an in-filter photosynthetic contribution from algae.

Physical air flow due to natural thermal currents may also enhance the

oxygenation as may the use of external fans or pumps which are a feature on

some industrial units.

Related Topics