Chapter: Environmental Biotechnology: Aerobes and Effluents

Pure Oxygen Systems

Pure Oxygen Systems

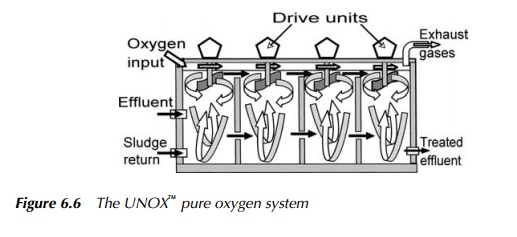

With process efficacy so closely dependent on aeration and the

ability to support a high microbial biomass, the use of pure oxygen to enhance

the effective levels of the gas dissolved in the effluent has an obvious

appeal. The UNOX process, which was developed by the Union Carbide Corporation

is probably amongst the best known of the pure oxygen activated sludge systems

and Figure 6.6 shows the general layout of the bioreactor vessels.

Pure oxygen obviously gives

a better oxygen transfer rate per unit volume of the bioreactor than can be

achieved using conventional aeration methods. In turn, this allows a heavier

organic loading per unit volume to be treated compared with ordinary air-fed

systems, which enables this system to be used to deal with stronger effluents

and permits a high throughput where space is restricted. Typically these

systems are fed using liquid oxygen tanks.

Despite their clear

advantages, pure oxygen systems suffer with some major drawbacks. For one

thing, the capital costs involved in installing them in the first place are

considerable, as are their running costs and maintenance requirement. The pure

oxygen itself represents an explosion risk, thus necessitating intrinsically

However, for some applications and for certain

kinds of effluents, they can prove particularly appropriate.

Related Topics