Chapter: Environmental Biotechnology: Aerobes and Effluents

Deep Shaft Process - Aerobes and Effluents

Deep Shaft Process

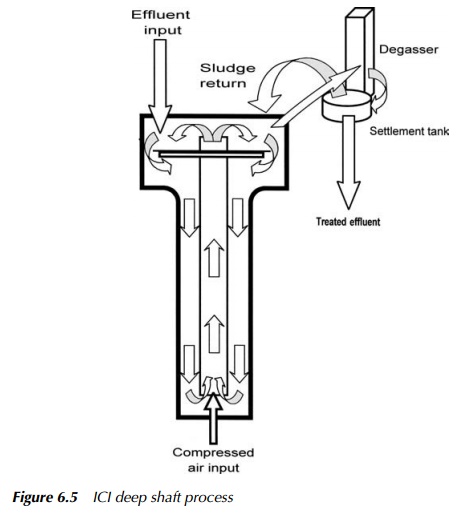

In many respects this is an activated sludge derivative, which was

borne out of ICI’s work on the production of proteins from methanol in the

1970s. Figure 6.5 shows the main features of the system, which is based around

a shaft 50 – 100 metres deep.

The shaft contains the

wastewater to be treated, compressed air being blown in at the base, which

travels up the central section, setting up an opposing counter flow in the

outer part of the shaft. Screened secondary effluent is allowed to settle and a

portion of the sludge produced is returned to the input zone, just as in a

traditional activated sludge tank, though degassing is required to remove

nitrogen and carbon dioxide bubbles from the floc to allow for proper sedimentation.

The high pressures at the

base force far more oxygen into solution than nor-mal, which aids aeration

enormously and allows the process to achieve an oxygen utilisation of around

90%, which is some 4.5 times better than conventional acti-vated sludge systems.

The bubble contact time produced, averaging 90 seconds or more, is over 6 times

longer than in standard diffused air systems. It has a low footprint, making it

ideal for use in restricted areas.

Related Topics