Chapter: Environmental Biotechnology: Aerobes and Effluents

Septic tank - Sewage Treatment

Septic tank

In many respects, the commonest rural solution to sewage treatment

beyond the reach of sewerage, namely the septic tank, makes use of an

intermediate form of land treatment. In the so-called cesspit, a sealed

underground tank, collects and stores all the sewage arising from the

household. At regular intervals, often around once a month dependent on the

capacity, it requires emptying and tanker-ing away, typically for spreading

onto, or injection into, agricultural land. By contrast, a septic tank is a

less passive system, settling and partially digesting the input sewage,

although even with a properly sized and well-managed regime the effluent

produced still contains about 70% of the original nutrient input. In most

designs, this is mitigated by the slow discharge of the liquid via an offtake

pipe into a ground soakaway, introducing the residual contaminants into the

soil, where natural treatment processes can continue the amelioration of the

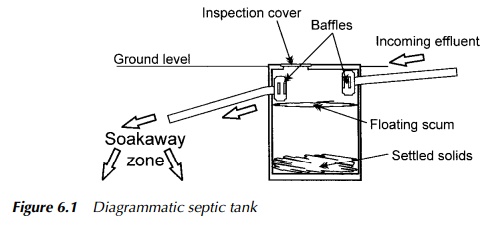

polluting constituents. There are various types of septic systems in use around

the world, though the most common, illustrated in Figure 6.1, is made up of an

underground tank, which is linked to some form of in situ soil treatment system, which usually consists of a land

drainage of some kind.

Since a system that is

poorly designed, badly installed, poorly managed or improperly sited can cause

a wide range of environmental problems, most espe-cially the pollution of both

surface and groundwaters, their use requires great care. One of the most

obvious considerations in this respect is the target soil’s ability to accept

the effluent adequately for treatment to be a realistic possibility

Under proper operation, the

untreated sewage flows into the septic tank, where the solids separate from the

liquids. Surfactants and any fat components tend to float to the top, where

they form a scum, while the faecal residues remaining after bacterial action

sink to the bottom of the tank, to form a sludge. The biodegradation of the

organic effluent in these systems is often only partially complete and so there

tends to be a steady accumulation of sediment within the tank, necessitating

its eventual emptying. This settling effect produces a liquid phase which is

permitted to flow out of the tank, along an overflow pipe situated towards the

top of the vessel and is discharged to the soil as previously described.

Internal baffles inside the tank are designed to retain the floating scum layer

and prevent undegraded faeces from leaving the system prematurely. If these

biosolids were permitted to wash out into the soil its ability to treat the

septic-tank effluent can readily become compromised, leading to a reduction in

the overall system efficiency.

The drainage arrangements

associated with a septic tank system are, arguably, perhaps the most important

part of this whole approach to sewage treatment and may be considered as

effectively forming an underground microbiological processing plant. Clearly,

it is of vital importance that the soil on any given site must be suitable for

the drainage to function reliably. The only way to be certain is, of course, by

means of a percolation test, though as a general rule, clay soils are unsuited

to this purpose. In circumstances of defined clay strata, particularly when

they exist close to the surface, it is highly unlikely that straightforward

drainage arrangements will prove satisfactory. Even in the absence of a high

clay content, soils which are either too fine or very coarse can also reduce

the effectiveness of this phase of the treatment system. The former can be a

problem because, like clay, it also resists effluent infiltration, the latter

because it permits it too quickly and thus retention time becomes inadequate

for the level of treatment needed.

A further consideration

which must be addressed in this respect is the position of the water table,

which may cause problems for the drainage system if it lies within half a metre

of the surface. Consequently in areas where this is a permanent or even

seasonal feature, the drains may be established much higher than would be

typical, frequently in close proximity to the soil surface. This brings its own

inevitable set of concerns, not least amongst them being that there can be a

very real possibility of the relatively untreated effluent breaking through to above

ground.

One solution to this

potential problem that has been used with some success is the sewage treatment

mound. Formed using clean sand or small gravel, the mound elevates the system

so that it sits a metre or so above the level of the seasonal highest water

table. The construction of the mound needs to receive careful consideration to

produce a design which suits the local conditions, while also guaranteeing an

even distribution of the septic tank effluent throughout the mound. Typically,

these systems are intermittently fed by a pump from a collec-tion point and the

rate at which the liquid off-take flows through the soil is a critical factor

in the correct sizing of the drainage mound. In the final analysis, the sizing

of all septic tank systems, irrespective of the details of its specific design,

depends on the amount of sewage produced, the type and porosity of soil at the

site and the rate at which water flows through it. Proper dimensional design

and throughput calculations are of great importance, since the efficacy of

septic systems is readily reduced when the set-up is overloaded.

Most modern installations

use premanufactured tanks, typically made of stable polymer and formed in a

spherical shape with a short shaft like the neck of a bottle forming a ground

level inspection point. They often have a series of internal baffles moulded

within them to facilitate the flow of liquids and retention of solids and

surface scum, together with the appropriate pipework inlets, outlets and gas

vents. This type of tank has become increasingly popular since they are readily

available, easier to site and can be operational much faster than the older

concrete designs.

The most common versions of

these consisted of two rectangular chambers which were originally built out of

brick or stone until the advent of techniques to cast concrete in situ. Sewage digestion was

incompletely divided into two stages, with gas venting from the primary chamber

and secondary also, in better designed systems. These were sometimes associated

with an alternative soil-dosing phase, known as seepage pits and soakaways, in

which the part-treated effluent arising from the septic tank is discharged into

a deep chamber, open to, and contiguous with, the soil at its sides and base.

This permitted the free translocation of liquid from the seepage pit into the

surrounding soil, the whole of the surrounding ground becoming, in effect, a

huge soakaway, allowing dilution and dispersal of the effluent and its

concomitant biotreatment within the body of the soil. In practice, provided the

character of the ground is truly suitable for this approach, effluent

infiltration and remediation can be very effective. How-ever, if the soil

porosity precludes adequate percolation, the potential problems are obvious.

Related Topics