Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Sleepers

Steel Channel Sleepers

Steel Channel Sleepers

In view of the great shortage of

wooden sleepers, steel channel sleepers have been developed by Indian Railways

particularly for use on girder bridges. Steel channel sleepers can be used for

welded plates, riveted plates, as well as open web girders.

Composite sleepers have been

developed indigenously in India as a replacement for wooden sleepers. These are

made from waste products such as used rubber tyres, and the manufacturers claim

a lifespan of about 40 years for these sleepers. The Patel Group of Industries

is one such firm that has developed these composite sleepers.

Composite sleepers are similar to

wooden sleepers and use similar fittings. These sleepers are under trial and

the results so far have been quite encouraging.

Steel Trough Sleeper

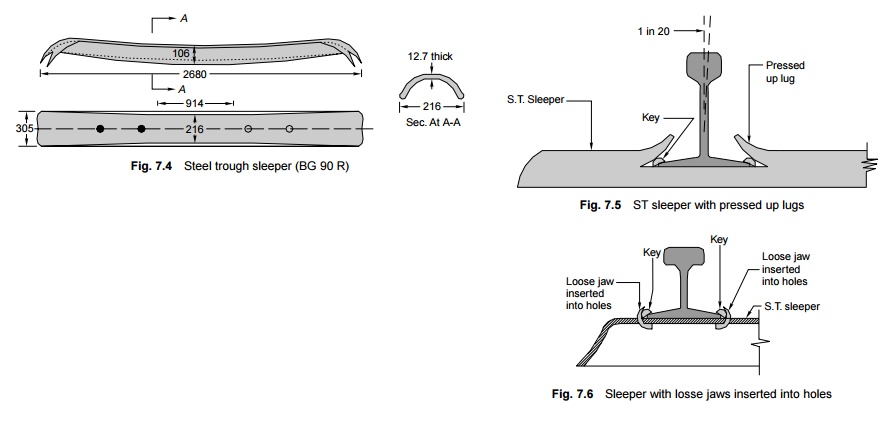

About 27% of the track on Indian Railways is laid on steel

sleepers (Fig. 7.4). The increasing shortage of timber in the country and other

economical factors are mainly responsible for the use of steel sleepers in

India. Steel sleepers have the following main advantages/disadvantages over

wooden sleepers.

Advantages

(a) Long life

(b) Easy to

maintain gauge and less maintenance problems

(c) Good

lateral rigidity

(d) Less

damage during handling and transport

(e) Simple

manufacturing process

(f) Very good

scrap value

(g) Free from

decay and attack by vermin

(h) Not

susceptible to fire hazards

Disadvantages

(a) Liable to

corrode

(b) Unsuitable

for track-circuited areas

(c) Liable to

become centre-bound because of slopes at the two ends

(d) Develops

cracks on rail seats during service

(e) Design is

rail specific

1 Design Features

The steel trough sleeper

essentially consists of a rolled steel plate of about 2 mm thickness pressed

into a suitable trough shape and the rail seat canted to 1 in 20. The ends of

the rolled section are flattened out in the shape of a spade to retain the

ballast. Two alternative types of sleepers have been designed for each rail

section as per the following details.

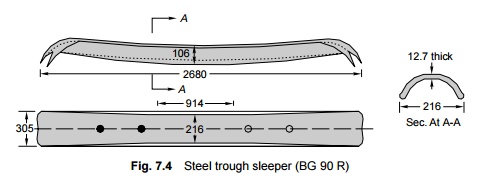

1. In one type, the lugs or jaws are

pressed out of the plate itself to accommodate the foot of the rail and the key

(Fig. 7.5). There are several maintenance problems with these pressed up lugs,

as they give way due to the movement of the keys as well as due to the

vibrations and impact of the moving loads.

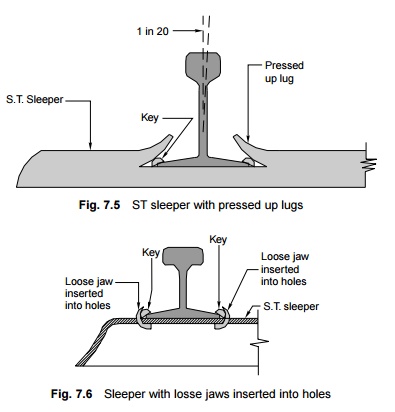

2. In order to obviate this defect,

another sleeper design has been adopted. In this design, two holes are punched

into either side of the plate to accommodate specially designed 'loose jaws'

(Fig. 7.6). The rails are held with the help of two standard keys driven either

into the pressed up lugs or into the loose jaws.

The adjustment of the gauge to

the extent of ± 3 mm is done by properly driving in the keys. In the

double-line section, the keys are driven in the direction of the traffic. The

approximate weight of a standard BG trough sleeper is 81 kg and that of an MG

sleeper is 35 kg. The steel trough (ST) sleeper has an average life of about 50

years. It is an acceptable type of sleeper for use with long welded rails

because of its lateral stability and its adaptability for use along with

elastic fastenings.

2 Classification

All steel sleepers conforming to

Indian Railways specifications T-9 are classified as first quality sleepers.

The sleepers not accepted as first quality but free from the following defects

are termed second quality steel trough sleepers.

(a) Inward

tilt at rail seat beyond the limits of 1 in 15 to 1 in 25

(b) Sleepers

with a twist

(c) Heavy

scale fitting or deep grooves or cuts

(d) Deep

guide marks at heads, blisters, etc.

All first quality sleepers are

normally marked by a green dot. Sleepers that have been rejected as first

quality sleepers on account of pipes, seams, and laps but are free from the

defects indicated above are marked with a cross (×) in yellow paint at the

centre. All other second quality steel trough sleepers are marked distinctly

with a 15-cm-wide strip of yellow paint at one end. Sleepers that are unfit as

second quality are given a distinct red paint mark to avoid mixing them up with

first and second quality sleepers during loading.

3 Maintenance Problems

It has been noticed that the keys

used to fix rails on steel sleepers tend to become loose due to the bending of

the pressed up lugs or due to wear at the rail seat. The holes also get

elongated during service. Special types of shims and liners are provided in

these cases to hold the gauge well. Mota Singh Liner is a very effective type

of liner used for holding the correct gauge for oblong holes with loose jaws.

Another maintenance problem with steel trough sleepers is that these tend to

become centre-bound if due care is not taken while packing. The ballast is

normally removed from the centre of the sleepers after packing so as to ensure

that centre binding of the sleepers does not take place. Sometimes the

alignment of steel sleeper tracks also gets affected by the overdriving of the

keys.

Related Topics