Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Sleepers

Maintenance of Concrete sleepers

Maintenance

of Concrete

sleepers

The

following points need attention in the maintenance of concrete sleepers.

i)

Concrete sleepers should normally be maintained

with heavy on-track tampers. For spot attention, MSP or off-track tampers may

be used. The size of chips for MSP should be 8 mm-30 mm as required

(b) Only 30

sleeper spaces are to be opened out at a time between two fully boxed track

stretches of 30 sleepers length each in case a LWR track exists.

(c) Concrete

sleepers should be compacted well and uniformly to give a good riding surface.

Centre binding of mono-block concrete sleepers should be avoided, for which the

central 800 mm of the sleeper should not be hard packed.

(d) Both ends

of the concrete sleepers should be periodically painted with anticorrosive

paint to prevent corrosion of the exposed ends of prestressing wires. In the

case of two-block sleepers, the tie bars should be examined every year, and if

any sign of corrosion is noticed, the affected portion should be painted with

an approved paint.

(e) Mechanical

equipment should be used for laying and maintaining concrete sleepers as far as

possible.

(f) Wherever

casual renewal of concrete sleepers is to be done, the normal precautions

followed for LWR tracks should be taken.

(g) The

elastic rail clip should be driven properly to ensure that the leg of the clip

is flush with the end face of the insert. Overdriving and underdriving should

be guarded against, as these cause eccentric loading on the insulations,

resulting in their displacement and in the variation of load.

(h) A

vigilant watch should be kept to ensure that no creep occurs in any portion of

the concrete sleeper track or there is no excessive movement near the switch

expansion joint (SEJ).

(i) It must

be ensured that the rubber pads are in their correct positions. Whenever it is

found that the rubber pads have developed a permanent set, these should be

replaced by new ones. Such examinations can be done at the time of destressing.

Toe load can also be lost due to ineffective pads.

(j) Nylon or

composite insulating liners used with Pandrol clips should be examined

periodically for signs of cracking and breakage. Adequate care should be

exercised when driving the clip at the time of installation to prevent damage.

(k) One of

the biggest problems regarding the maintenance of a concrete sleeper track is

that the elastic rail clips get seized with malleable cast iron (MCI) inserts

not only during regular maintenance, but also during destressing, other

incidental works, and derailments. The following remedial measures are

suggested.

(i) At the

base depot, all the elastic rail clips and MCI inserts should be thoroughly

cleaned. Grease should then be applied on the central leg of the elastic rail

clip (ERC) and the eye of the MCI insert. These should then be driven into

place at the time of assembly of the service pan.

ii)

During service all the elastic rail clips must be

taken out from the MCI inserts and cleaned with a wire brush and emery paper,

specially on the central leg. The eyes of the MCI inserts must also be cleaned

of any debris or rusted material. The central leg of the ERC should then be

covered with good quality grease. The eyes of the MCI inserts should be smeared

with the same grease before the treated ERCs are driven back. This has to be

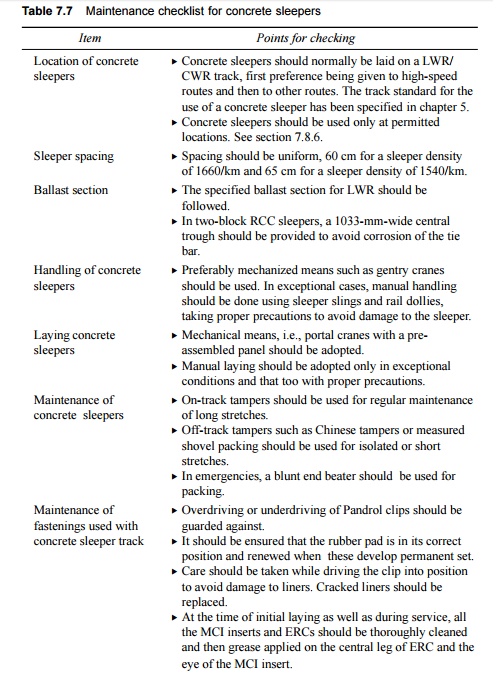

repeated every one year in corrosion prone areas. A maintenance checklist for

concrete sleepers is given in Table 7.7.

Table 7.7 Maintenance checklist

for concrete sleepers

Related Topics